Self-bearing tensile wind energy power cable

A power cable and tensile type technology, applied in the field of self-supporting tensile type wind energy power cables, can solve the problems of not very long life of conductors and conductive cores, not very tight stranded conductors, general flexibility of conductors, etc. Moisture-proof and good sealing, not easy to break, the effect of reducing the weight of the cable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

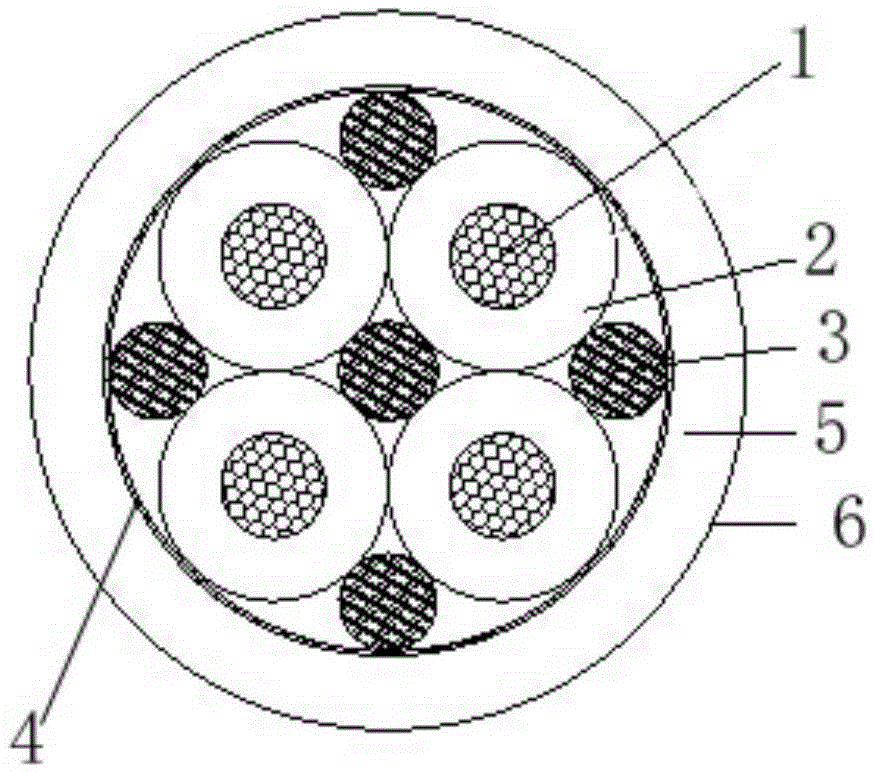

[0014] Such as figure 1 As shown, a self-supporting tensile type wind energy power cable includes a cable core, which is extruded on the outer isolation belt 4 and the outer sheath 6 of the cable core; the main improvement is that the plurality of tubular conductors 2 of the cable core It is twisted with the rubber filling strip 3 extruded between the tubular conductor 2; a load-bearing core 1 is provided at the center of the tubular conductor, and the stress point of the conductor is concentrated on the central load-bearing core. During the winding process of the cable, The annealed copper wire of the inner conductor is protected, and it is not easy to break; a metal tensile tube 5 is provided between the isolation belt 4 and the outer sheath 6, so that the cable has good compression resistance, moisture resistance and sealing performance, and embossing can improve its performance. bending properties.

[0015] The use of tubular conductors can save metal materials and reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com