Electromagnetic type verticality controller

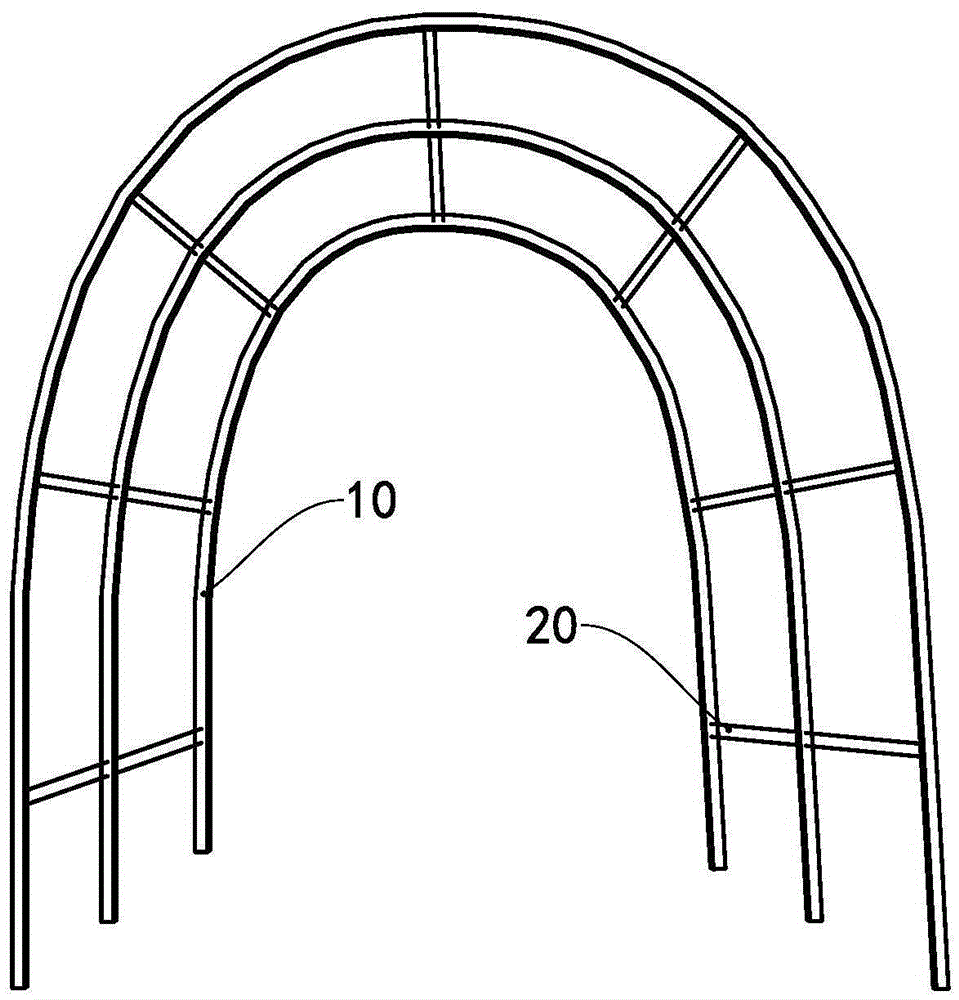

A verticality, electromagnetic technology, applied in the field of electromagnetic verticality controller, can solve the problems of difficult control of the spacing and verticality of the initial steel arch installation, inability to ensure safety, inconvenient construction and operation, etc., to shorten the process. The effect of cycle time, labor intensity reduction, and construction efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

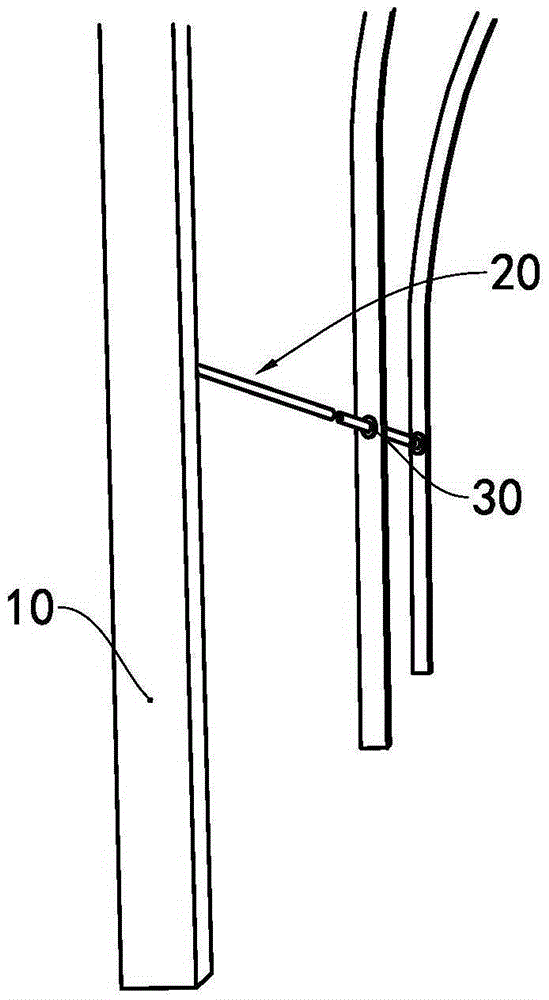

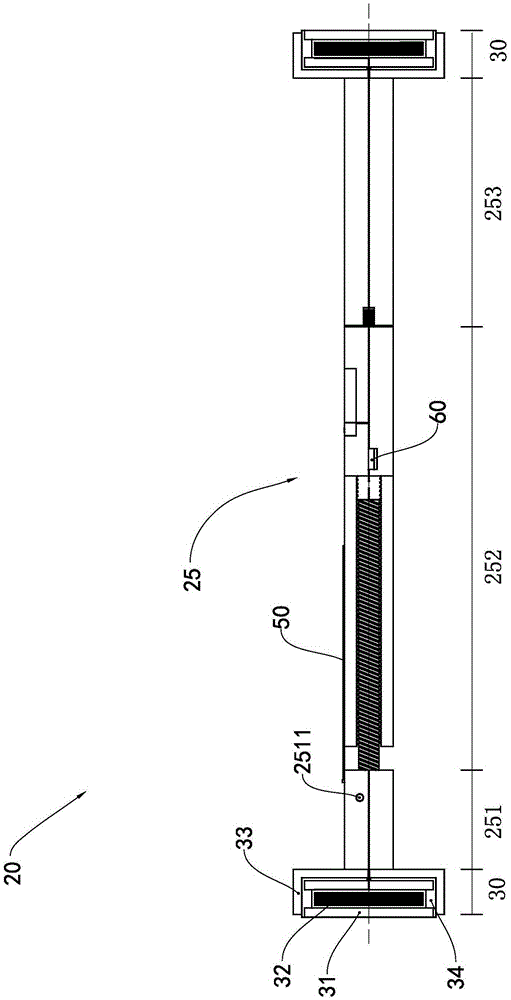

[0029] see image 3 , the electromagnetic verticality controller 20 of the present embodiment includes a main shaft 25 that can be telescopically adjusted, two electromagnetic chucks 30 are respectively arranged at both ends of the main shaft 25, and electric wires 40 connecting the main shaft 25 and the two electromagnetic chucks 30 , also includes a power supply 71 installed on the main shaft 25 (such as Figure 4 shown) and a control switch (not shown), and the power supply 71 and the control switch are connected in series with the two electromagnetic chucks 30 .

[0030] see Figure 4 with Figure 5 , the main shaft 25 includes a front shaft 251, a middle shaft 252 and a rear shaft 253, a scale 50 is installed on the front shaft 251, one end is fixedly connected with the electromagnetic chuck 30, the other end is movably connected with the middle shaft 252, and the two ends of the rear shaft 253 are respectively It is fixedly connected with the central shaft 252 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com