LED power source, filling glue and encapsulating technique for filling glue

A technology of LED power supply and filling glue, which is applied in the direction of light source, circuit layout, lighting device, etc., can solve the problems of waterproof performance damage, LED power supply damage, power supply component extrusion damage, etc., to maintain waterproof performance, improve service life, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

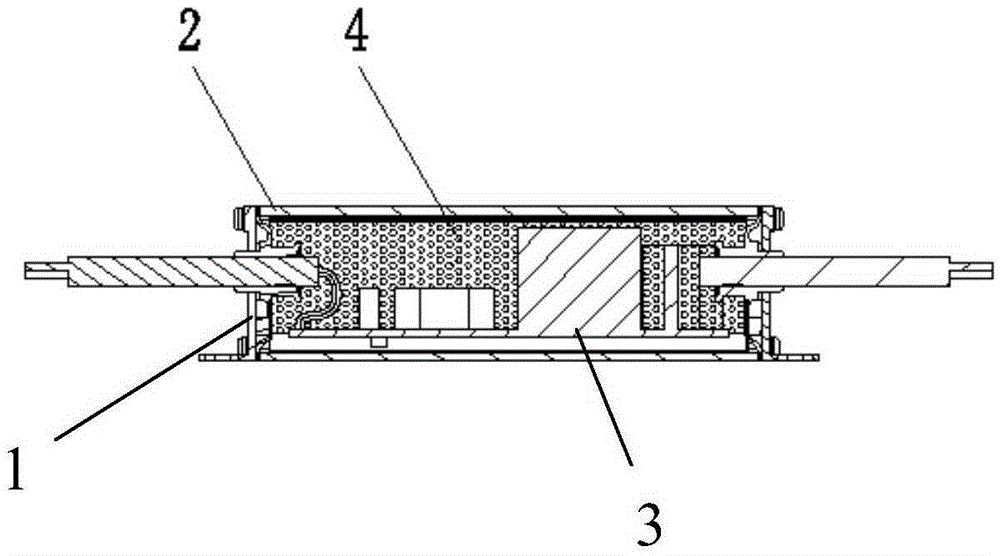

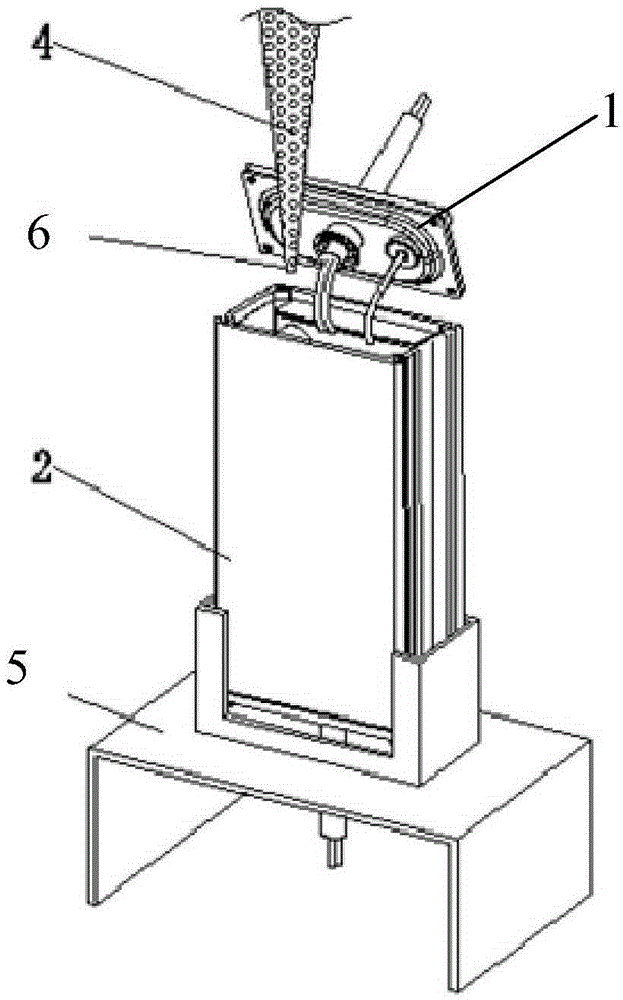

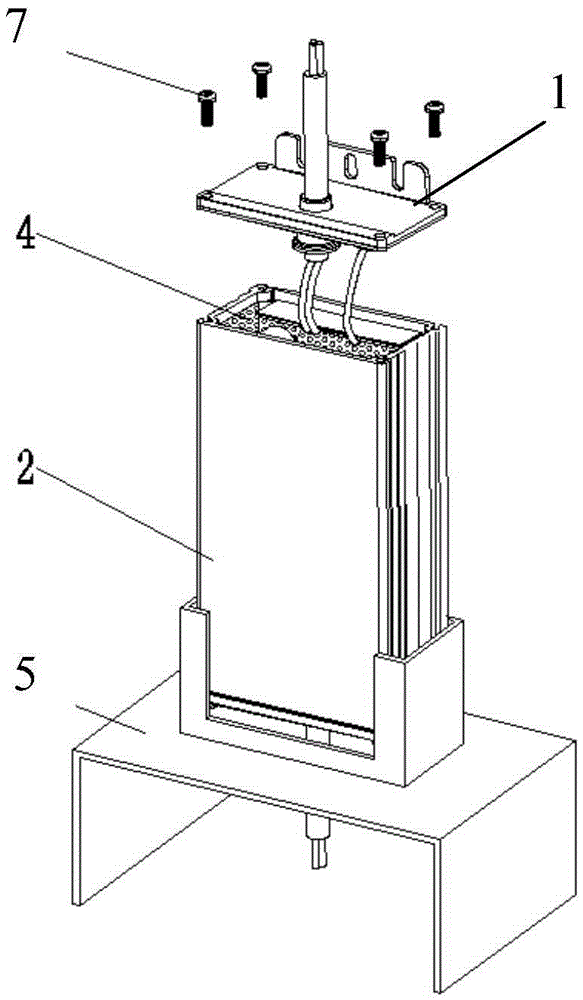

[0025] Such as figure 1 As shown, this embodiment provides an LED power supply, including a power supply housing 2, an end cover 1, a power supply assembly 3 and a filler 4; the two ends of the power supply housing 2 are respectively covered with end covers 1, and The inside of 2 is provided with the above-mentioned power supply assembly 3 and filled with filling glue 4 .

[0026] Among them, the filler includes filler and thermally conductive potting glue; the filler accounts for 20% to 80% of the components. The filler can be any one or a combination of quartz sand, glass beads and ceramic sand. The thermally conductive potting compound can be any one or a combination of silica gel, polyurethane, and epoxy resin.

[0027] For the manufacture of the above-mentioned LED power supply, it is necessary to provide a potting process of filling glue, such as figure 2 and image 3 shown, with the following steps:

[0028] Step 101, use potting equipment to mix and stir the fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com