Low-speed state stably-accelerating throttle valve

A throttle and throttle shaft technology, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of precise control of flow balance between two throttle valves and difficult adjustment methods, so as to avoid sudden and sudden increase , stable change, precise control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

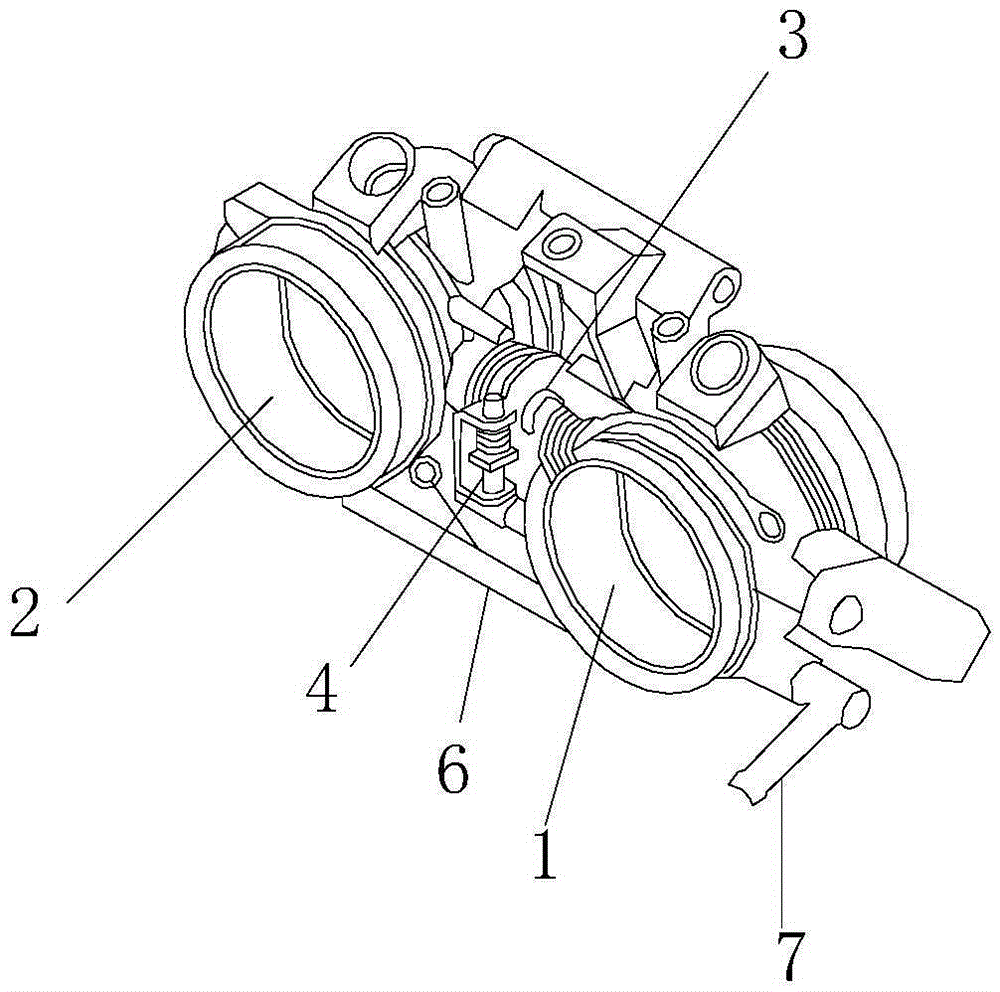

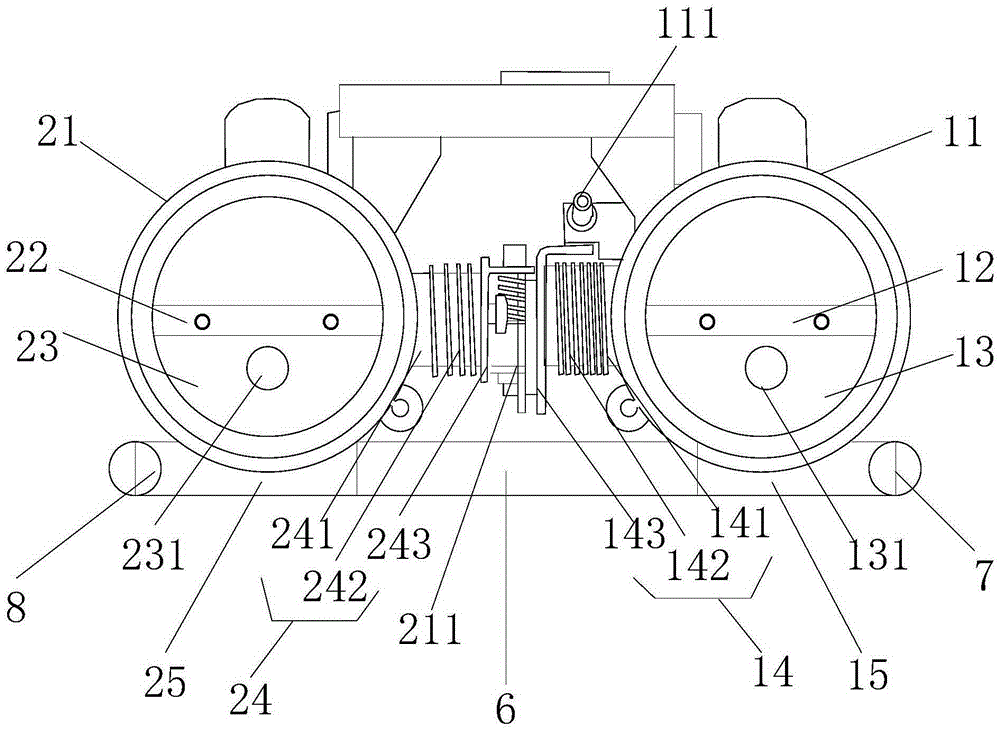

[0055] As shown in the figure, a throttle valve for a two-cylinder engine provided in this embodiment includes a first throttle valve 1, a second throttle valve 2 and a connecting mechanism 3;

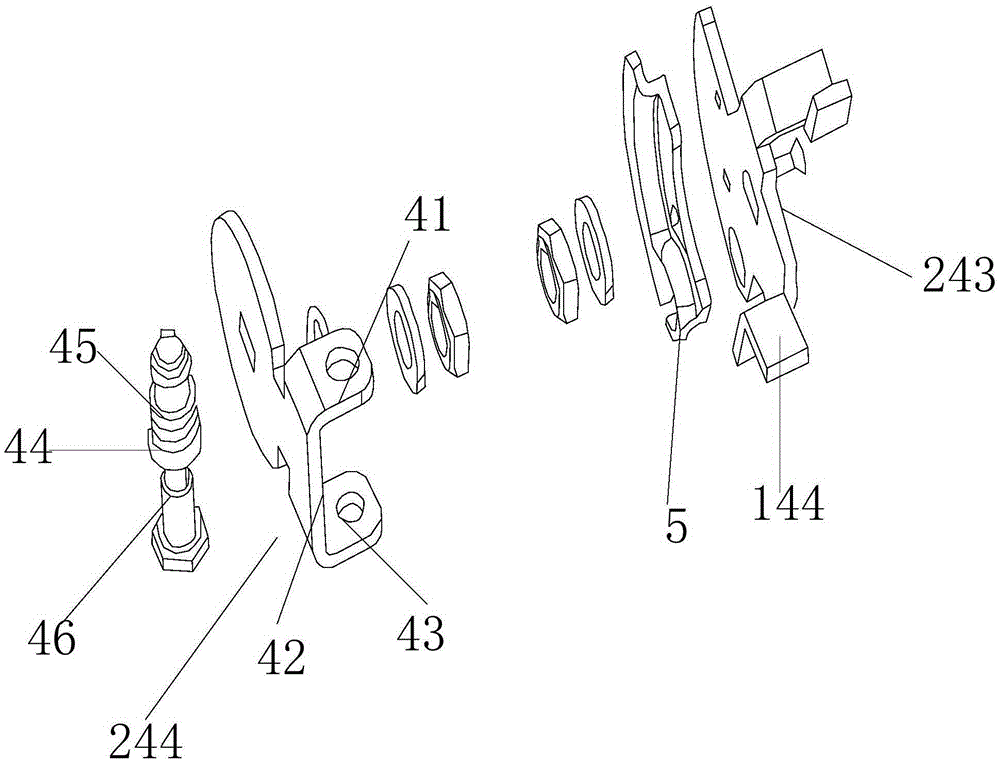

[0056] The first throttle valve includes a first throttle body 11, a first throttle shaft 12, a first throttle plate 13 and a first return mechanism 14; the first throttle shaft extends along the radial direction of the first throttle body Setting; the first throttle plate is set along the first throttle shaft; the first throttle plate is used to control the air flow of the pipeline formed by the first throttle body; the first return mechanism is set on the first The throttle body is connected to the first throttle shaft; the first return mechanism is used to restore the idle state of the first throttle plate;

[0057]The second throttle valve includes a second throttle body 21, a second throttle shaft 22, a second throttle plate 23 and a first return mechanism 24; the second throttle ...

Embodiment 2

[0096] The dual-cylinder engine throttle valve provided by this embodiment, the throttle valve body provided by this embodiment is made of aluminum die-casting, and then the throttle valves of two kinds of master-slave mechanisms that produce throttle valves are set on the main body; two throttle valves The diameters are 46 to 52mm respectively, and are used for two engine displacements; the first throttle valve provided in this embodiment is arranged on the right side of the main body, and the throttle valve is the master cylinder valve; the second throttle valve is arranged on the left side, and the throttle valve is Auxiliary cylinder throttle; there is a mud-proof cover between the main and auxiliary cylinder throttle; the mud-proof cover must be between the two throttles; the fuel injector and fuel rail are assembled on the engine assembly line; the fuel injector is installed on the on the subject. The fuel injector and fuel rail are fixed on the main body, and the fuel r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com