Oil well cavitation method physicochemical heat blockage relieving technology

A legal and oil well technology, applied in the field of physical and chemical thermal blockage removal technology of oil well cavitation method, can solve the problems of low temperature of injection liquid, inconvenient popularization and application, affecting chemical reaction, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

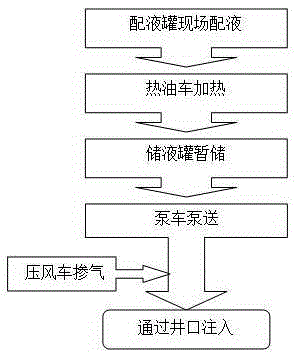

[0042] Embodiment 1: as attached figure 2 As shown, the working system is composed of a liquid distribution tank, a hot oil truck, a pump truck, a wind press, and ground pipeline connections; the liquid is prepared in the liquid distribution tank or at the liquid distribution station, heated by a hot oil truck, connected to the liquid storage tank, and then The injection is injected through the wellhead under pressure by the pump truck with the assistance of the wind press.

[0043] The construction process is:

[0044] 1. Preparations before construction: Check that the wellhead and wellbore meet the construction conditions; connect ground equipment and pipelines; detect high-pressure manifolds and various components, and conduct pressure tests on pipelines to ensure that the pipelines are pressure-bearing.

[0045] 2. Preparation of blockage-removing liquid: prepare blockage-removing liquid in the liquid dispensing tank according to the design formula and liquid volume, or...

Embodiment 2

[0048] Embodiment 2: as attached image 3 As shown, there is no major change in the process system, and different liquid preparation methods and heating methods can be used. In the present invention, the core of the heating device principle is energy conversion, and the most extensive one is the conversion of electrical energy into thermal energy. When conditions permit, electric energy and other methods can also be used for heating.

[0049] In the above, the working system uses surface pump trucks to establish a controllable and periodic oil layer plugging removal process system for oil layers, which can work together with different types of plugging fluids. Send it downhole to make it generate high-speed liquid flow in the wellbore.

[0050] In the foregoing, construction equipment should be versatile for the same type of operation. To adapt to the nature of the fluid medium; to be able to cope with the adjustment of injection parameters. Commonly used construction equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com