Anti-cold bridge node for window of steel structure industrial plant

A technology for preventing cold bridges in industrial plants, applied to building components, building structures, and thermal insulation. It can solve the problems of reduced building thermal insulation performance, reduced thermal performance, and cold bridges, so as to achieve good heat insulation and eliminate cold bridges. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail in conjunction with the accompanying drawings.

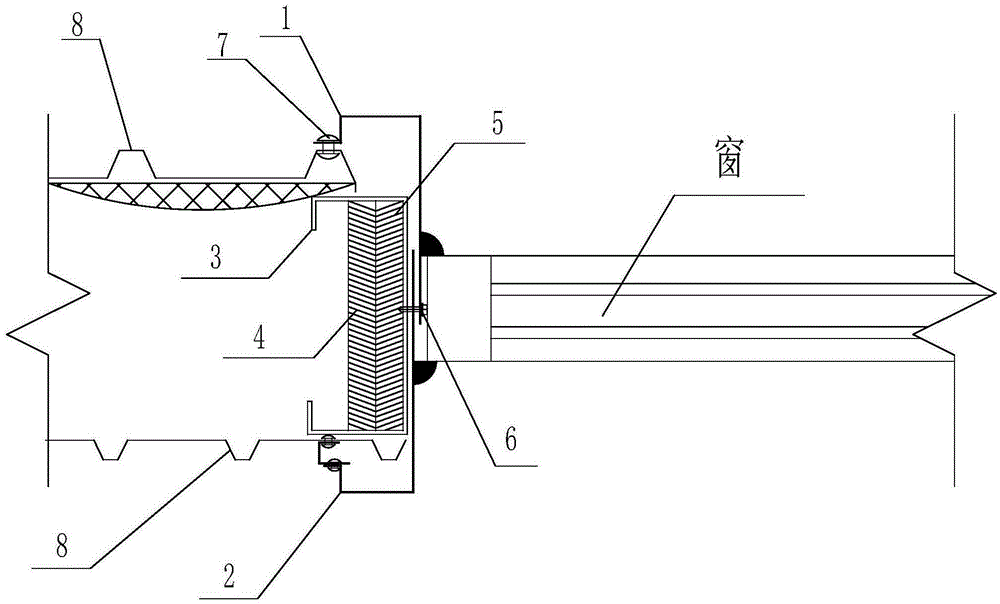

[0010] Such as figure 1 As shown, a window anti-cold bridge node of a steel structure industrial factory building includes a first window profiled steel plate 1, a second window profiled steel plate 2, purlins 3, extruded plastic plates 4, and adhesive tape 5;

[0011] After the straight end of the first window profiled steel plate 1 is connected with the straight end of the second window profiled steel plate 2 by self-tapping screws, it is then firmly connected to the square groove purlin 3;

[0012] The bent ends of the first window profiled steel plate 1 and the second window profiled steel plate 2 are fixedly connected to the color steel plate 6 through the fixing cap 7;

[0013] An adhesive tape 5 is arranged in the purlin 3 of the square groove;

[0014] An extruded board 4 is arranged on the outside of the adhesive tape.

[0015] The connection between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com