Solvent-free synthetic leather and manufacturing method thereof

A manufacturing method and technology of synthetic leather, applied in textiles and papermaking, etc., can solve the problems of inability to achieve diversification of color, quality and trend effect, affect the service life of release paper, affect the peeling of paper leather, etc., and achieve international market competitiveness Improve, improve service life, prevent excessive penetration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

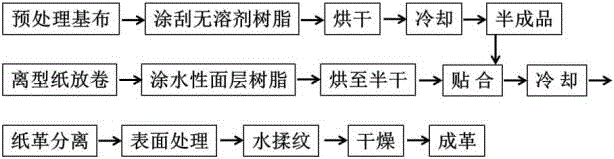

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 The manufacture of solvent-free sofa leather

[0040] (1) Preparation of solvent-free polyurethane slurry and water-based surface layer slurry (parts by weight)

[0041]a) Preparation of solvent-free slurry: 100 parts of hydroxyl-terminated aromatic solvent-free polyurethane, 12.0 parts of polycarbodiimide crosslinking agent, 5.0 parts of color paste, 10.0 parts of wood powder, and 0.3 parts of TegoFlow300 type leveling agent at room temperature Mix evenly;

[0042] b) Preparation of water-based surface layer slurry: 100 parts of internal cross-linked aromatic water-based surface layer polyurethane with a modulus of 60Mpa and a solid content of 40%, 20 parts of water-based color paste, and 0.3 parts of BYK-034 water-based defoamer , 0.5 parts of RM-2020NPR water-based thickener are mixed evenly, and made into a surface layer slurry with a viscosity of 3000mPa.s;

[0043] (2) Base cloth pretreatment

[0044] The base fabric is unrolled, stretched, and the...

Embodiment 2

[0052] The manufacture of embodiment 2 solvent-free garment leather

[0053] (1) Preparation of solvent-free polyurethane slurry and water-based surface layer slurry (parts by weight)

[0054] a) Preparation of solvent-free polyurethane slurry: 100 parts of amino-terminated aliphatic solvent-free polyurethane, 10.0 parts of dicyclohexyl diisocyanate, 10.0 parts of color paste, 5.0 parts of light calcium carbonate, 1.0 parts of TEGOGlide100 type leveling agent at room temperature Mix evenly;

[0055] b) Preparation of water-based surface layer slurry: 100 parts of internal cross-linked aliphatic water-based surface layer polyurethane with a modulus of 50Mpa and a solid content of 30%, 10 parts of water-based color paste, 0.3 parts of Foamex1495 water-based defoamer, TT Mix 0.5 parts of -935 water-based thickener evenly, and make a surface layer slurry with a viscosity of 3000mPa.s;

[0056] (2) Base fabric pretreatment: Base fabric is unrolled, stretched, and then sprayed wit...

Embodiment 3

[0064] Embodiment 3 The manufacture of solvent-free automotive interior leather

[0065] (1) Preparation of solvent-free polyurethane slurry and water-based surface layer slurry (parts by weight)

[0066] a) Preparation of solvent-free polyurethane slurry: 50 parts of amino- and hydroxyl-terminated aliphatic solvent-free polyurethanes, 7.5 parts of polycarbodiimide and polyaziridine crosslinking agents, 8.0 parts of color paste, and 2.0 parts of carbon black , 3.0 parts of pottery clay, 3.0 parts of barium sulfate, 0.8 parts of Silok8450 type leveling agent and mix well at room temperature;

[0067] b) Preparation of water-based surface layer slurry: 100 parts of internal cross-linked aliphatic water-based surface layer polyurethane with a modulus of 50Mpa and a solid content of 35%, 15 parts of water-based color paste, 0.2 parts of Silok4650 water-based defoamer, ASE Mix 0.4 parts of -60 type water-based polyurethane thickener evenly, and make a surface layer slurry with a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com