A crushing and decomposing combined rag machine

A rag rag, decomposing technology, which is applied in the directions of decomposing fibrous substances, textile decomposition and recovery, and cutting of textile materials, etc. Rag efficiency, complete crushing, and satisfying the effect of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

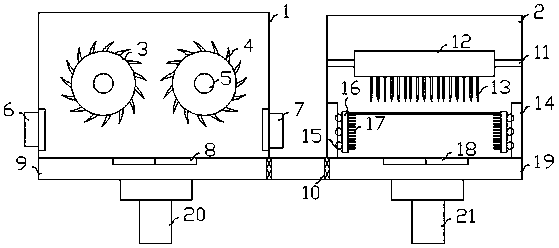

[0016] Such as figure 1 As shown, a crushing and decomposing combined rag machine includes a crushing rag 1 and a decomposing rag 2, the crushing rag 1 and the decomposing rag 2 are connected through a through hole 10, and the broken A rag roller 3 is arranged inside the rag 1, a rag knife 4 is arranged on the cylindrical surface of the rag roller 3, a rotating shaft 5 is arranged inside the rag roller 3, and the two sides of the rag 1 are respectively The first blower 6 and the second blower 7 are provided, and the bottom of the crushing rag machine 1 is provided with a crushing rag machine discharge pipe 9, between the crushing rag machine 1 and the crushing rag machine discharge pipe 9 Connected by the broken rag machine valve 8, the inside of the decomposed rag machine 2 is provided with a fixed frame 12, the decomposed rag machine 2 and the fixed frame 12 are connected by a swing rod 11, and the bottom of the fixed frame 12 is connected with several Decomposition needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com