Method for electrochemically synthesizing beta-PbO2 on rotating disk electrode

A technology of rotating disk electrodes and disk electrodes, which is applied in the field of material preparation and electrochemistry, and achieves high stability and good reproducibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

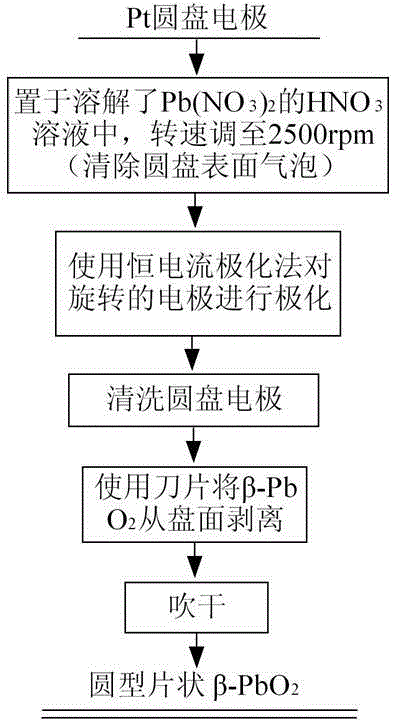

[0016] Such as figure 1 As shown, the β-PbO was electrochemically synthesized on the rotating disk electrode 2 method, using a three-electrode system: the working electrode is a Pt disc electrode (the surface area of the Pt disc is 0.196cm 2 , the rotation speed of the Pt disc is 200rpm), the reference electrode is a saturated calomel electrode, and the auxiliary electrode is a surface area of 2cm 2 Platinum sheet placed in β-PbO 2 In the bath (β-PbO 2 The plating solution is composed of Pb(NO 3 ) 2 Join HNO 3 solution, where Pb(NO 3 ) 2 Medium Pb 2+ with HNO 3 The molar ratio is 4:1, HNO 3 The concentration of the solution is 0.15mol / L), at a synthesis temperature of 40°C and a polarization current of 40mA / cm 2 β-PbO can be deposited on the surface of the Pt disk under constant current polarization for 2h 2 , the β-PbO 2 Circular flaky β-PbO was prepared by peeling off the surface of Pt disk and blowing dry 2 .

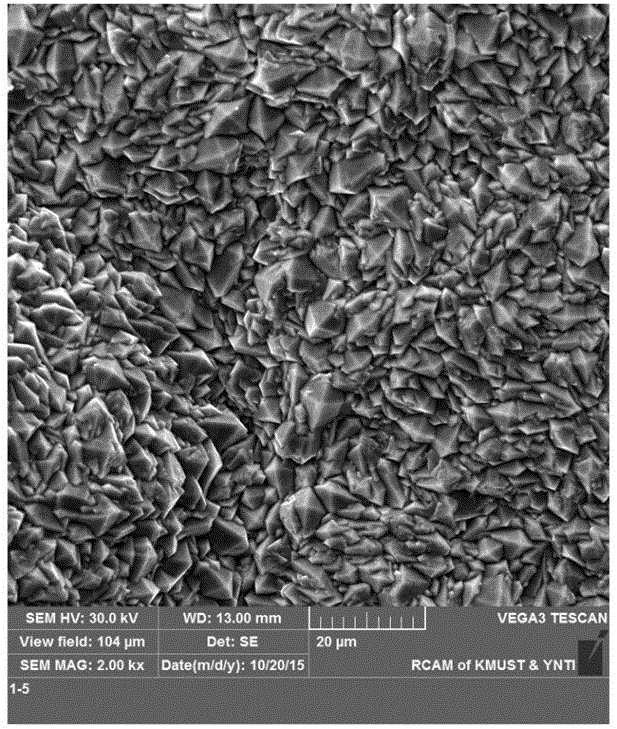

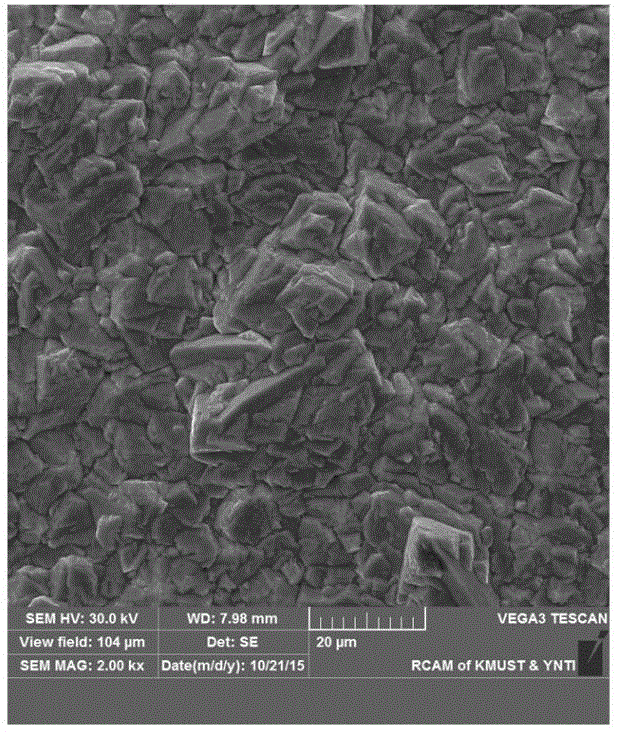

[0017] The circular flake-shaped β-PbO prepa...

Embodiment 2

[0019] Such as figure 1 As shown, the β-PbO was electrochemically synthesized on the rotating disk electrode 2 method, using a three-electrode system: the working electrode is a Pt disc electrode (the surface area of the Pt disc is 0.196cm 2 , Pt disc rotation speed is 300rpm), the reference electrode is a saturated calomel electrode, and the auxiliary electrode is a surface area of 2cm 2 Platinum sheet placed in β-PbO 2 In the bath (β-PbO 2 The plating solution is composed of Pb(NO 3 ) 2 Join HNO 3 solution, where Pb(NO 3 ) 2 Medium Pb 2+ with HNO 3 The molar ratio is 7:1, HNO 3 The concentration of the solution is 0.1mol / L), at a synthesis temperature of 40°C and a polarization current of 40mA / cm 2 β-PbO can be deposited on the surface of the Pt disk under constant current polarization for 2h 2 , the β-PbO 2 Circular flaky β-PbO was prepared by peeling off the surface of Pt disk and blowing dry 2 .

[0020] The circular flake-shaped β-PbO prepared in this ...

Embodiment 3

[0022] Such as figure 1 As shown, the β-PbO was electrochemically synthesized on the rotating disk electrode 2 method, using a three-electrode system: the working electrode is a Pt disc electrode (the surface area of the Pt disc is 0.196cm 2 , Pt disc rotation speed is 300rpm), the reference electrode is a saturated calomel electrode, and the auxiliary electrode is a surface area of 2cm 2 Platinum sheet placed in β-PbO 2 In the bath (β-PbO 2 The plating solution is composed of Pb(NO 3 ) 2 Join HNO 3 solution, where Pb(NO 3 ) 2 Medium Pb 2+ with HNO 3 The molar ratio is 5:1, HNO 3 The concentration of the solution is 0.12mol / L), at a synthesis temperature of 50°C and a polarization current of 50mA / cm 2 β-PbO can be deposited on the surface of Pt discs under constant current polarization for 4h 2 , the β-PbO 2 Circular flaky β-PbO was prepared by peeling off the surface of Pt disk and blowing dry 2 .

[0023] The circular flake-shaped β-PbO prepared in this em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com