Method for electrochemically synthesizing alpha-PbO2 on rotating disk electrode

A technology of rotating disk electrode and disk electrode, which is applied in the fields of material preparation and electrochemistry to achieve the effect of high stability and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

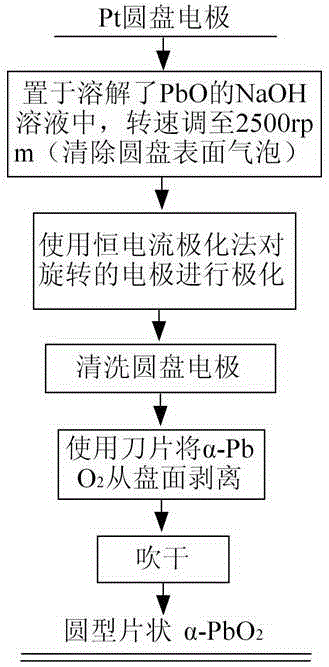

[0016] like figure 1 As shown, the α-PbO was electrochemically synthesized on the rotating disk electrode 2 method, using a three-electrode system: the working electrode is a Pt disc electrode (the surface area of the Pt disc is 0.196cm 2 , Pt disc rotation speed is 400rpm), the reference electrode is a saturated calomel electrode, and the auxiliary electrode is a surface area of 2cm 2 Platinum sheet placed in α-PbO 2 In the bath (α-PbO 2 The plating solution is added from PbO to NaOH solution, where NaOH and PbO are dissolved in HPbO - The molar ratio is 30:1, the concentration of NaOH solution is 3mol / L), the synthesis temperature is 40℃, and the polarization current is 15mA / cm 2 α-PbO can be deposited on the surface of the Pt disk under constant current polarization for 4h 2 , the α-PbO 2 Circular flaky α-PbO prepared by peeling off the surface of Pt disk and blowing dry 2 .

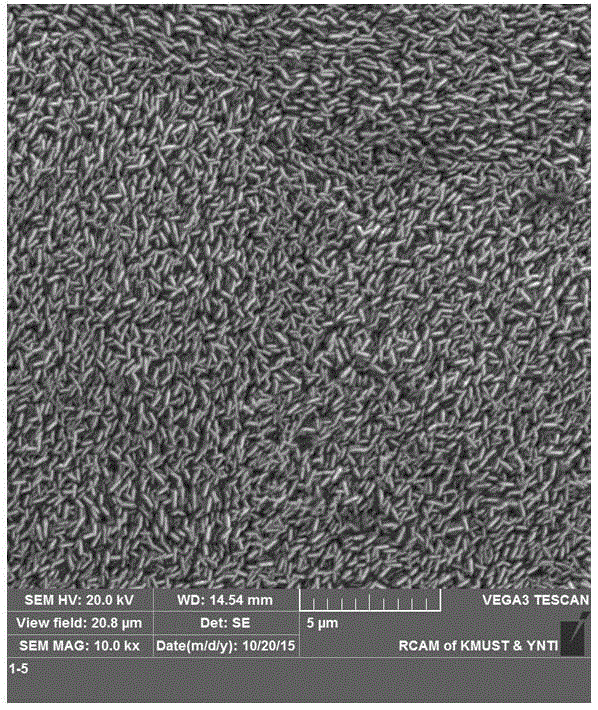

[0017] The circular flake-shaped α-PbO prepared in this example 2 It is black, with m...

Embodiment 2

[0019] like figure 1 As shown, the α-PbO was electrochemically synthesized on the rotating disk electrode 2 method, using a three-electrode system: the working electrode is a Pt disc electrode (the surface area of the Pt disc is 0.196cm 2 , Pt disc rotation speed is 400rpm), the reference electrode is a saturated calomel electrode, and the auxiliary electrode is a surface area of 1cm 2 Platinum sheet placed in α-PbO 2 In the bath (α-PbO 2 The plating solution is added from PbO to NaOH solution, where NaOH and PbO are dissolved in HPbO - The molar ratio is 20:1, the concentration of NaOH solution is 3mol / L), the synthesis temperature is 30℃, and the polarization current is 10mA / cm 2 α-PbO can be deposited on the surface of the Pt disk under constant current polarization for 4h 2 , the α-PbO 2 Circular flaky α-PbO prepared by peeling off the surface of Pt disk and blowing dry 2 .

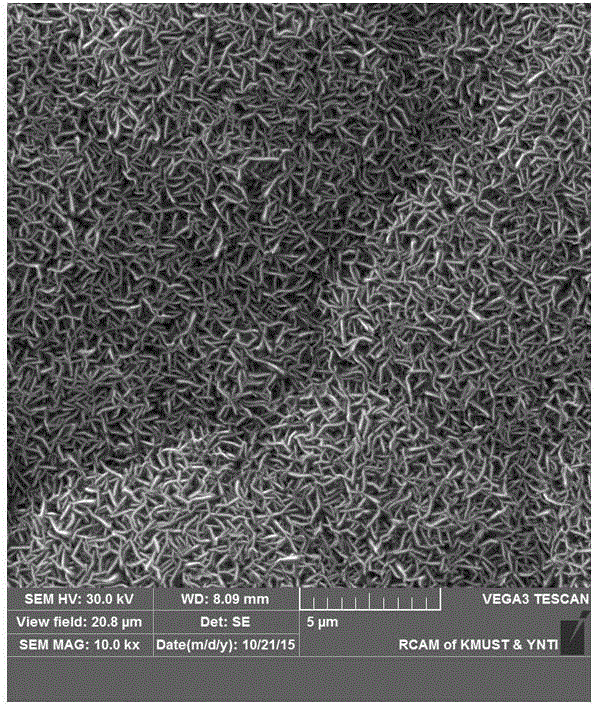

[0020] The circular flake-shaped α-PbO prepared in this example 2 It is black, with m...

Embodiment 3

[0022] like figure 1 As shown, the α-PbO was electrochemically synthesized on the rotating disk electrode 2 method, using a three-electrode system: the working electrode is a Pt disc electrode (the surface area of the Pt disc is 0.196cm 2 , Pt disc rotation speed is 400rpm), the reference electrode is a saturated calomel electrode, and the auxiliary electrode is a surface area of 1cm 2 Platinum sheet placed in α-PbO 2 In the bath (α-PbO 2 The plating solution is added from PbO to NaOH solution, where NaOH and PbO are dissolved in HPbO - The molar ratio is 40:1, the concentration of NaOH solution is 4mol / L), the synthesis temperature is 40℃, and the polarization current is 15mA / cm 2 α-PbO can be deposited on the surface of Pt discs under constant current polarization for 8 hours 2 , the α-PbO 2 Circular flaky α-PbO prepared by peeling off the surface of Pt disk and blowing dry 2 .

[0023] The circular flake-shaped α-PbO prepared in this example 2 It is black, with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com