Transfer tape

A technology without substrates and tapes, applied in the direction of adhesives, natural rubber adhesives, film/sheet adhesives, etc., can solve problems such as damage to electronic devices such as batteries, etc., to achieve convenient operation, simple synthesis, and good adhesion. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

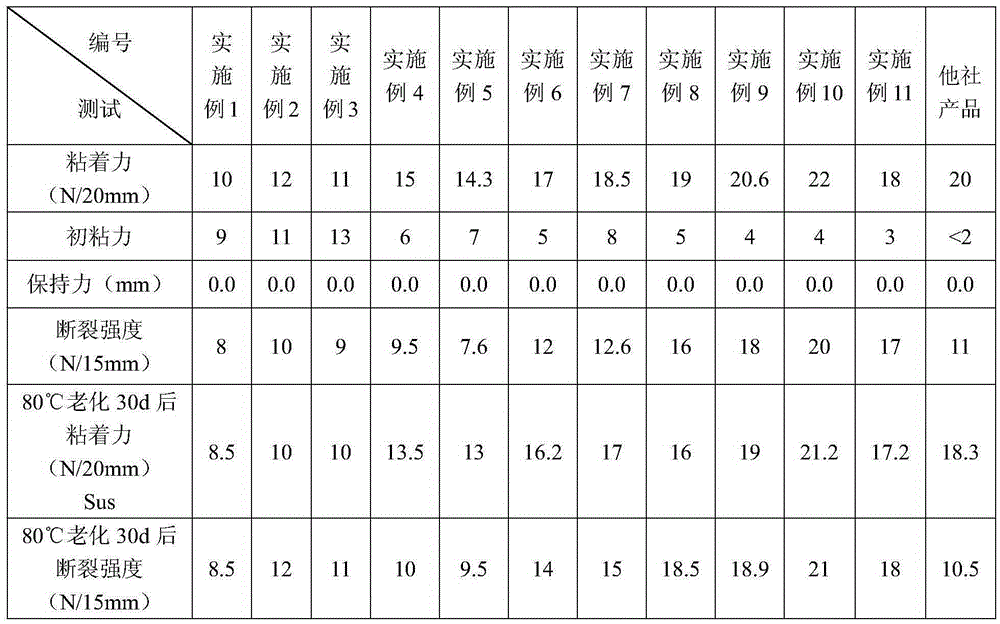

Examples

Embodiment 1

[0025] The base material-free tape of this embodiment comprises an adhesive layer with a thickness of 150 μm and a coated double-sided release paper layer, wherein the ratio of the two-sided release force of the double-sided release paper layer is 1:3, and the adhesive layer and the release paper layer The side with the higher release force of the paper layer is bonded. The raw materials for the preparation of the adhesive layer include the following components in parts by weight: 80 parts of styrene-butadiene rubber, 80 parts of terpene resin, 40101.0 parts of naphthenic oil, 1.0 part of dioctyl phthalate (DOP), 2,2' - 4.0 parts of methylenebis(4-methyl-6-tert-butylphenol), 4.8 parts of color paste (HolcoflexWhite216.2867).

[0026] The preparation method of the adhesive layer is as follows:

[0027] (1) Dissolving at least one of the rubber elastic body in toluene, ethyl acetate, butanone solvent, the solid content of the rubber solution made is 50%;

[0028] (2) dissolvin...

Embodiment 2

[0032] The non-substrate adhesive tape of this embodiment includes an adhesive layer with a thickness of 150 μm and a coated double-sided release paper layer, wherein the ratio of the release force on both sides of the double-sided release paper layer is 1:3. The raw materials for the preparation of the adhesive layer include the following components in parts by weight: 80 parts of styrene-butadiene rubber, 100 parts of terpene resin, 1.0 parts of naphthenic oil, 1.0 part of dioctyl phthalate (DOP), 2,2' - 4.0 parts of methylenebis(4-methyl-6-tert-butylphenol), 4.8 parts of color paste (HolcoflexWhite216.2867).

[0033] The preparation method and coating process of the adhesive layer are the same as in Example 1.

Embodiment 3

[0035] The non-substrate adhesive tape of this embodiment includes an adhesive layer with a thickness of 150 μm and a coated double-sided release paper layer, wherein the ratio of the release force on both sides of the double-sided release paper layer is 1:3. The raw materials for the preparation of the adhesive layer include the following components in parts by weight: 80 parts of styrene-butadiene rubber, 80 parts of terpene resin, 1.0 part of dioctyl phthalate (DOP), 2,2'-methylene bis( 4-methyl-6-tert-butylphenol) 4.0 parts, color paste (HolcoflexWhite216.2867) 4.8 parts.

[0036] The preparation method and coating process of the adhesive layer are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com