Oily sludge gel particle profile control agent and preparation method thereof

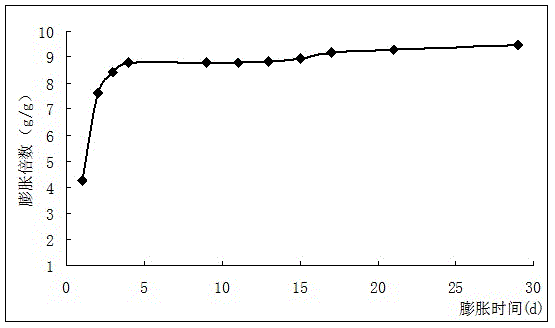

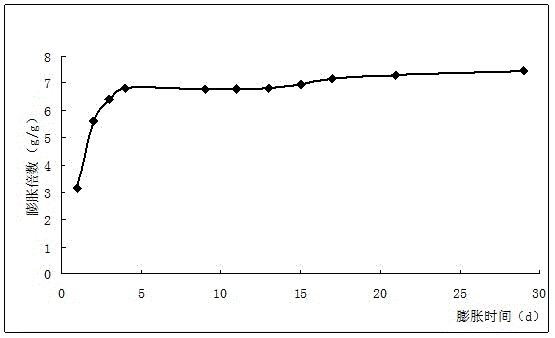

A technology of mud gel particles and profile control agent, which is applied in the field of oily sludge gel particle profile control agent and its preparation, which can solve the problems of poor suspension and achieve good swelling ability, delayed swelling performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

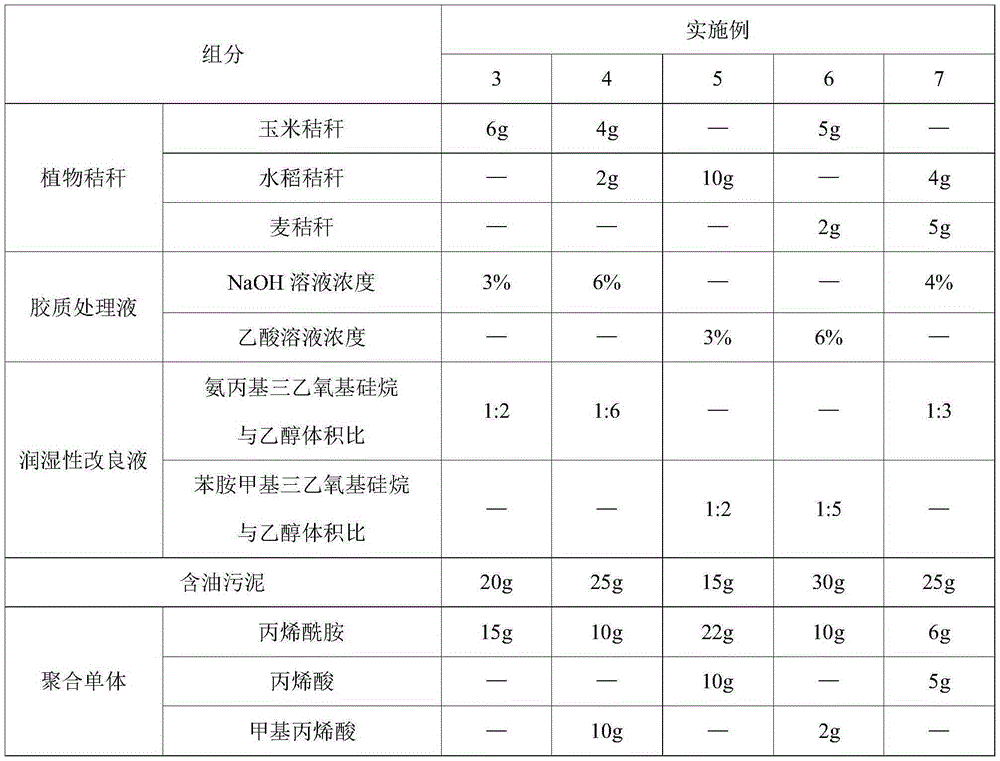

Examples

Embodiment 1

[0028] A profile control agent for oily sludge gel particles, achieved through the following steps:

[0029] Physically and mechanically pulverize the corn stalks, cut them into 6mm, soak them with clean water, shake off the excess water and let them hang in the air, then soak the corn stalks with 5% NaOH solution for 48 hours, rinse them with tap water until neutral, put Dry in an oven set at 105°C; then soak the corn stalks with a solution made of aminopropyltriethoxysilane and ethanol at a volume ratio of 1:4 for 6 hours, take it out, and put it in an oven set at 105°C After drying, add 10 g of the treated corn stalks to 25 g of oily sludge slurry, mix and stir evenly, and obtain oily sludge wrapped with corn stalks.

[0030] In a mixing container with a stirring device, add 20 g of 40% acrylamide, 0.09 g of N-methylol propionamide, 35 g of oily sludge wrapped with corn stalks, 44.84 g of pure water, and adjust the pH with the reaction regulator sodium carbonate When the v...

Embodiment 2

[0035] A profile control agent for oily sludge gel particles, achieved through the following steps:

[0036] Physically and mechanically pulverize the rice straw, cut it into 8mm, soak it with clean water, shake off the excess water and let it air, then soak the rice straw with 4% acetic acid solution for 36 hours, rinse it with tap water until neutral, put Dry in an oven set at 105°C; then soak the rice straw with a solution made of anilinomethyltriethoxysilane and ethanol at a volume ratio of 1:6 for 4 hours, take it out, and put it in an oven set at 105°C After drying, add 8 g of the treated rice straw into 20 g of oily sludge slurry, mix and stir evenly, and obtain oily sludge wrapped with rice straw.

[0037] In a mixing container with a stirring device, add 20 g of 40% acrylamide, 0.09 g of N-methylol propionamide, 28 g of oily sludge wrapped with rice straw, 51.81 g of pure water, and adjust the pH with the reaction modifier sodium carbonate When the value reaches 7, 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com