Soymilk machine with separate motor and blade

A soymilk machine and blade technology, applied in beverage preparation devices, household appliances, applications, etc., can solve problems such as machine head damage, motor temperature rise, difficult cleaning, etc., to prevent water ingress, increase service life, and facilitate cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

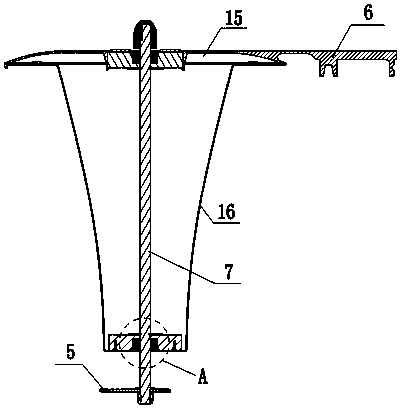

[0020] A soymilk machine in which the motor and the blade are separated, including a machine base 1, a cup body 2, a machine head and a blade 5, a motor 4 is arranged in the machine head, and a motor mounting seat 3 is extended upward on one side of the machine base, and the motor 4 can be installed on the motor The seat moves up and down; the cup body 2 is arranged on the machine base, a cup cover 6 is arranged on the cup body 2, a connecting shaft 7 is arranged in the center of the cup cover 6, the blade 5 is arranged at the lower end of the connecting shaft 7, and the upper end of the connecting shaft 7 is connected to the motor The output shaft of the motor drives the rotation of the connecting shaft through the rotation of the motor, and finally drives the blade to rotate to crush the beans. The invention separates the design of the motor from the blade, and the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com