Full-control profiling elevating cotton top-cutting machine

A topping machine and cotton technology, applied to agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve the problems of low automation, high replacement frequency, and reduced immediacy of topping operations, and achieve stable and controllable performance. High degree of automation and low operating power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

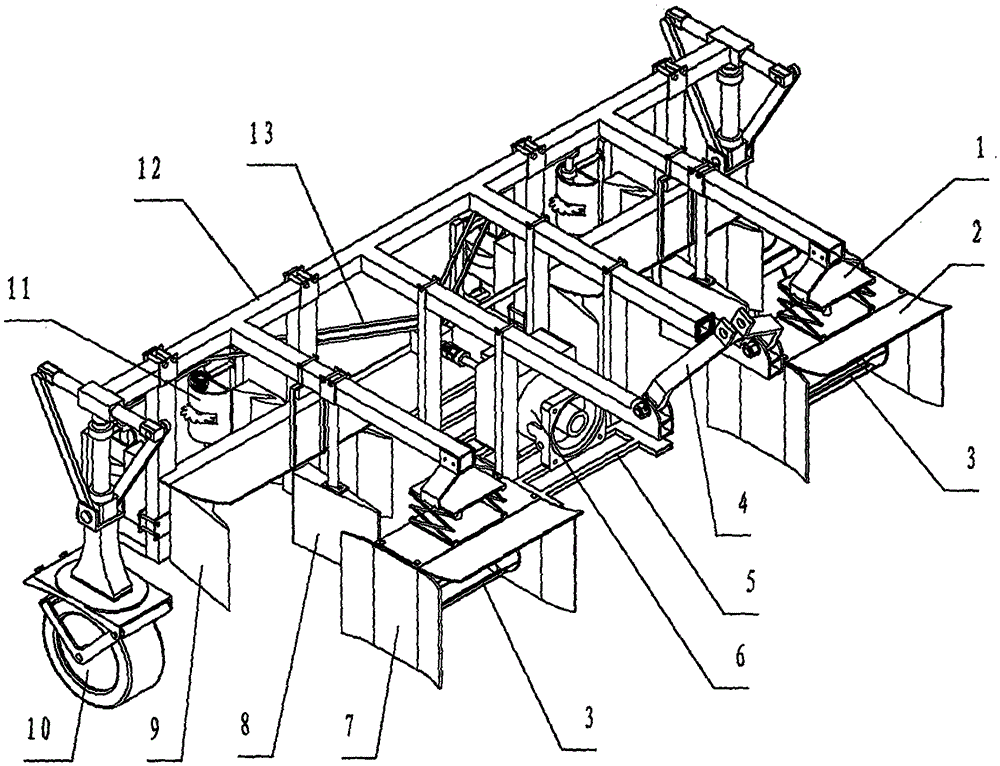

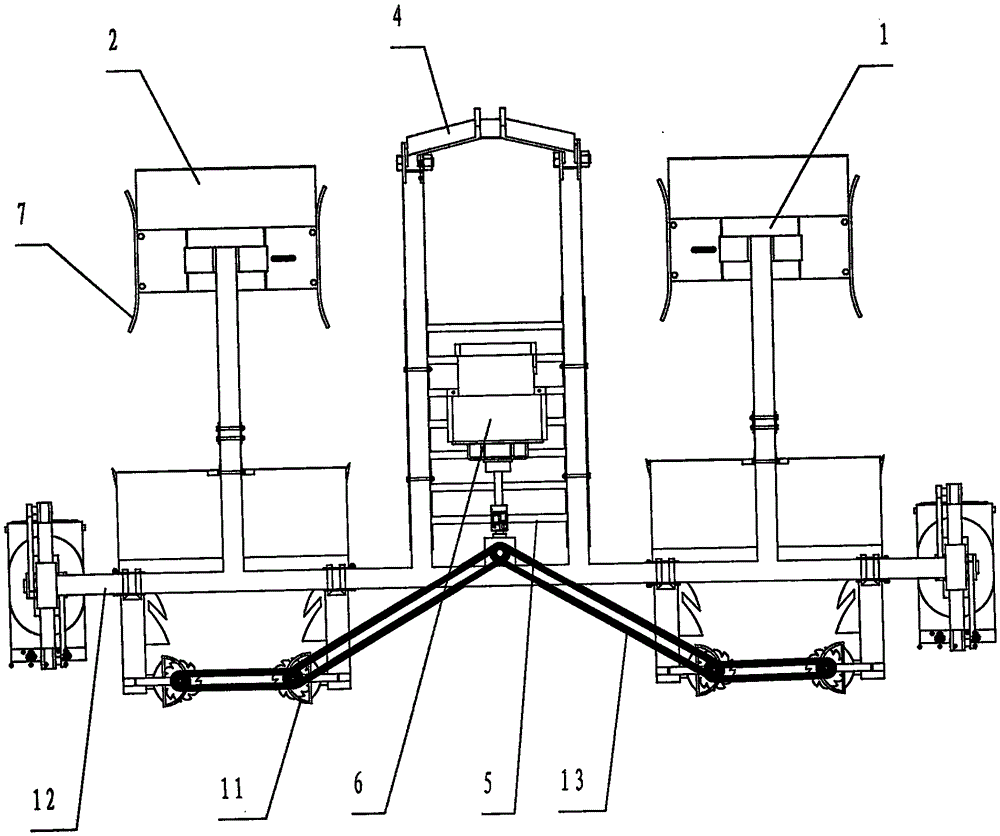

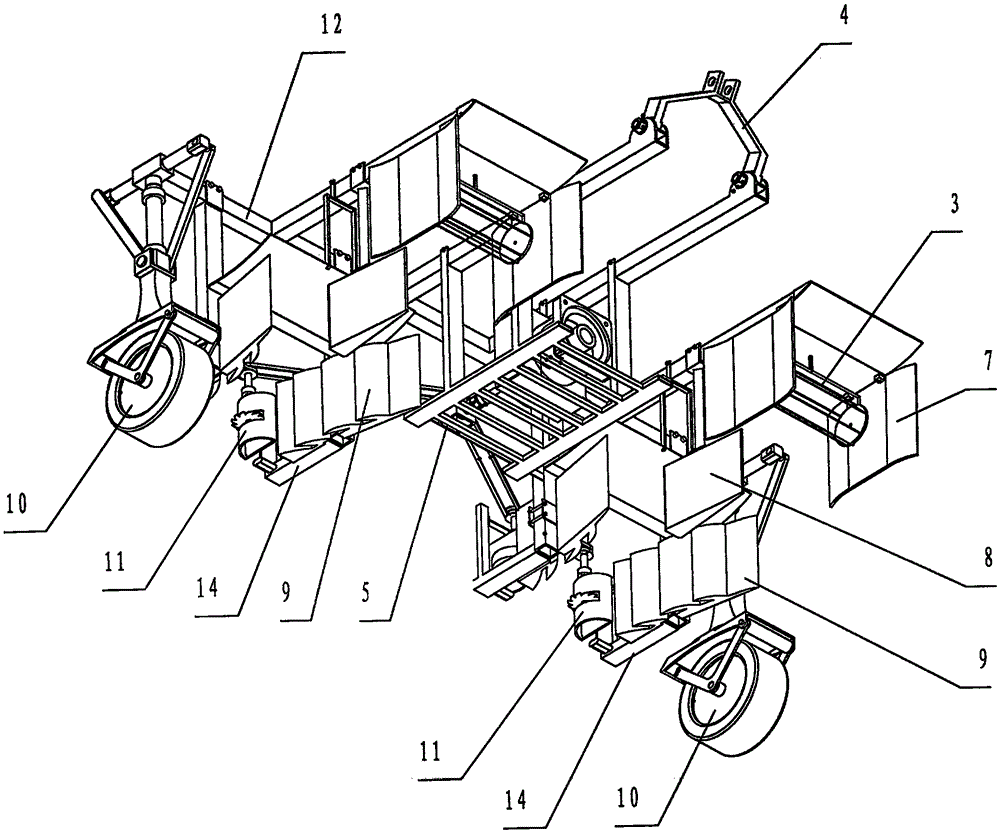

[0021] Example: see attached Figures 1 to 6 , the present invention is composed of a frame 12, a suspension frame 4, a topping device, a profiling device, a lifting device, an overhead shock-absorbing ground wheel 10, a grass-supporting and dividing device and a transmission device; the suspension frame 4 is arranged on the frame. 12 Front; the front part of the frame is provided with an electric lifting plate 1, the topping device is composed of a front topping device and a rear topping device, and the front topping device is arranged under the electric lifting plate 1 , the front topping device is a drum cutter 3, the drum cutter 3 is located under the profiling device, and the rear topping device is a knife cylinder 11, and the knife cylinder 11 is provided under the rear of the frame 12; The profiling device is arranged in front of the electric lifting plate 1, and the profiling device is a profiling induction curved plate 2; the frame 12 is provided with a motor table 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com