High-voltage explosion-proof three-phase asynchronous motor with low temperature rise

A three-phase asynchronous, flame-proof technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems affecting the performance and reliability of the whole machine, poor heat dissipation effect, temperature rise, etc., to ensure performance and convenience. Process quality control, to achieve the effect of temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

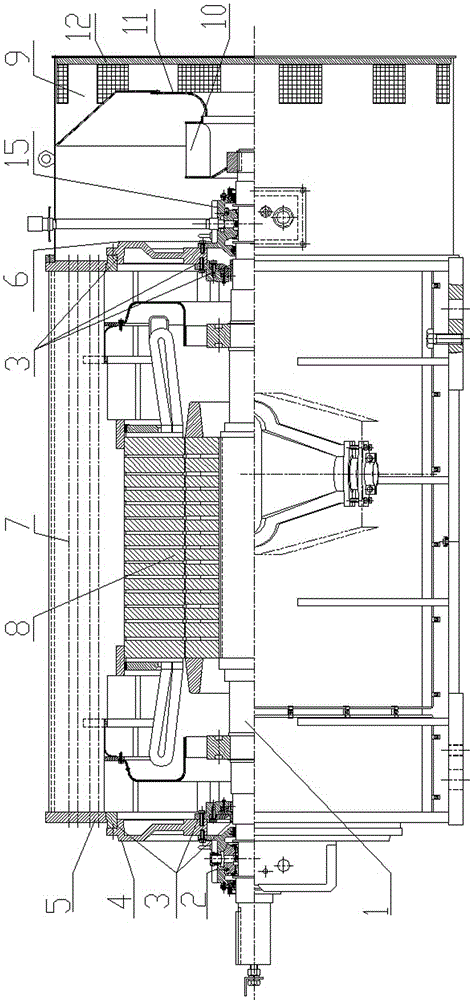

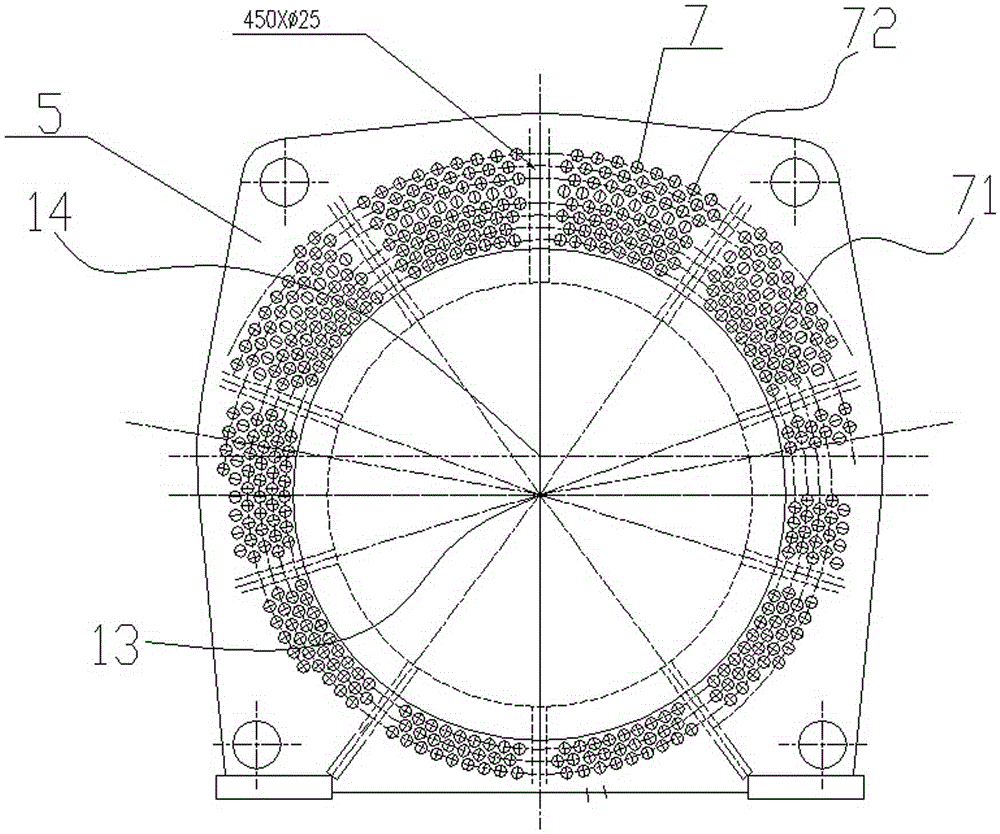

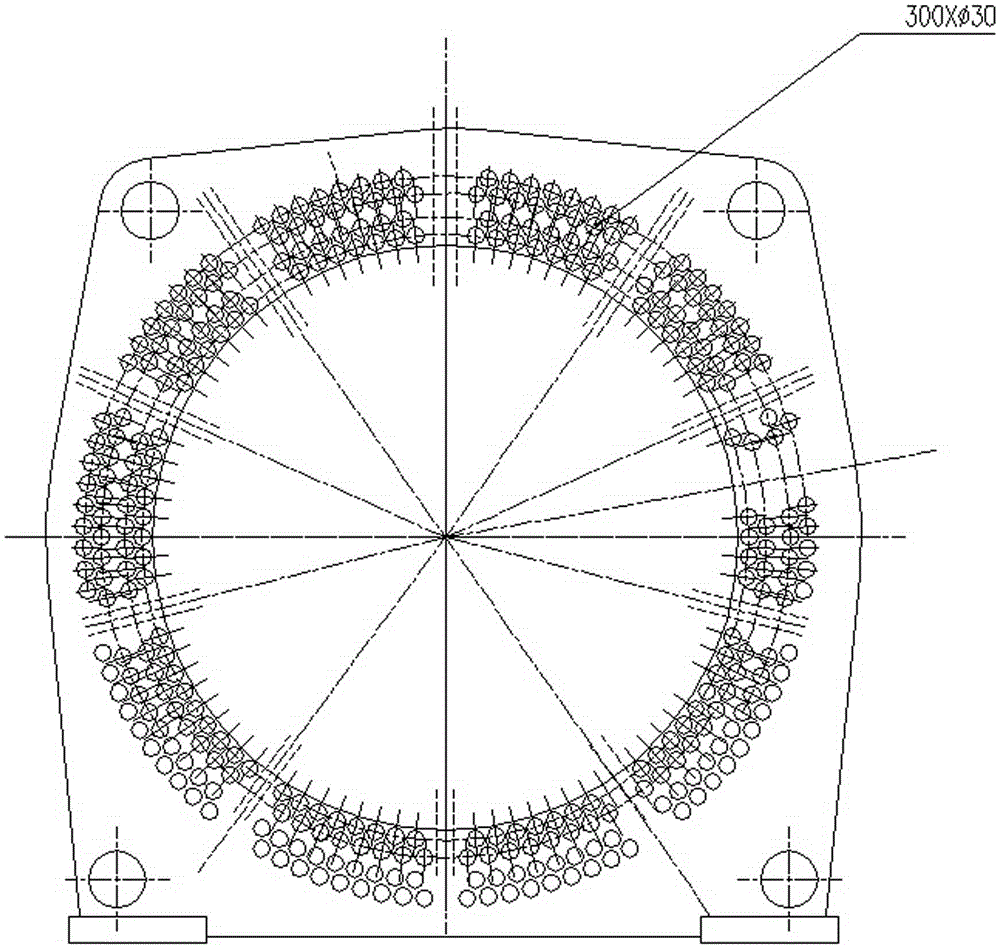

[0026] Such as figure 1 and figure 2 As shown, a low-temperature rising high-voltage flameproof three-phase asynchronous motor of the present invention includes a frame 5, a rotor 1 and a stator 8 are arranged in the frame 5, and a motor and a motor are arranged at the front and rear ends of the rotor 1 respectively. The front end cover 4 and the rear end cover 6 connected by the base 5, the center of circle 13 of the rotor 1 and the stator 8 are lower than the center of circle 14 of the base 5, and the base 5 adopts an eccentric structure so that the center of the base 5 is aligned with the center of the rotor 1 and the stator. 8 The center of the circle is different, the center height of the motor is reduced by one frame size due to the eccentricity of the frame, and the vibration of the motor and the field installation are improved. Both the front end cover 4 and the rear end cover 6 are cast iron end covers, which are optimized to cast iron end covers compared with the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com