High-pressure liquid cutting system and application thereof as well as dismantling method for waste lithium ion battery

A lithium-ion battery, high-pressure liquid technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve problems such as inability to completely eliminate sparks, dust, and inability to flexibly adapt to batteries of various sizes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

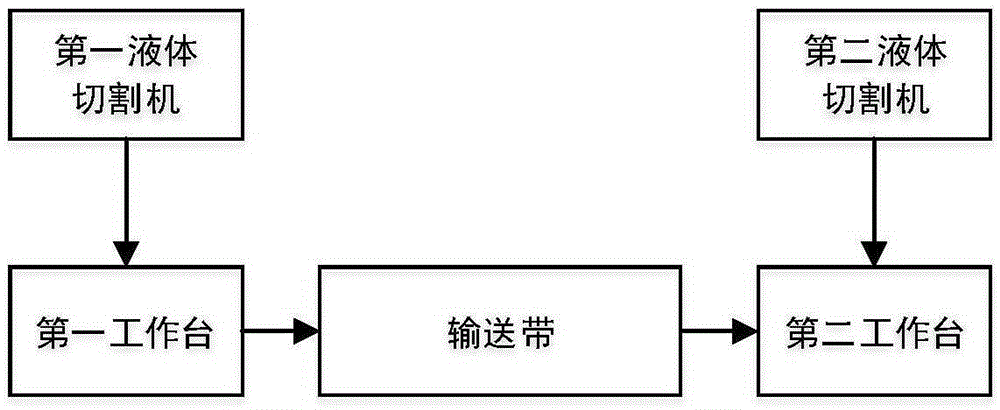

[0079] See attached figure 1 , The high-pressure liquid cutting system provided in Embodiment 1 of the present invention includes a first workbench, a first liquid cutter, a conveyor belt, a second workbench, and a second liquid cutter;

[0080] The high-pressure liquid injection point of the first liquid cutting machine is set above the first workbench, and the first liquid cutting machine is used to cut the object to be cut once to obtain a disassembled object;

[0081] One end of the conveyor belt is set near the first workbench, and the other end of the conveyor belt is set near the second workbench, and the conveyor belt is used to transport the primary dismantled objects from the first workbench to the second workbench;

[0082] The high-pressure liquid injection point of the second liquid cutting machine is arranged above the second workbench, and the second liquid cutting machine is used for performing secondary cutting on the primary dismantling object to obtain the s...

Embodiment 2

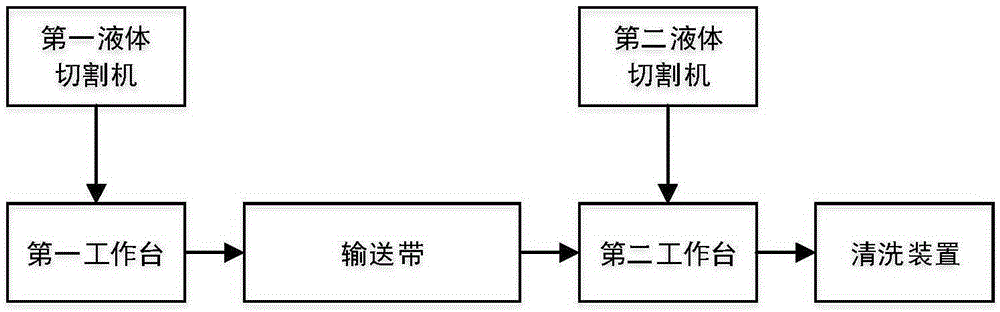

[0097] See attached figure 2 , improve on the basis of the high-pressure liquid cutting system provided in Embodiment 1 of the present invention, the high-pressure liquid cutting system provided in Embodiment 2 of the present invention also includes a rinsing device, which is used for rinsing the secondary dismantled objects .

Embodiment 3

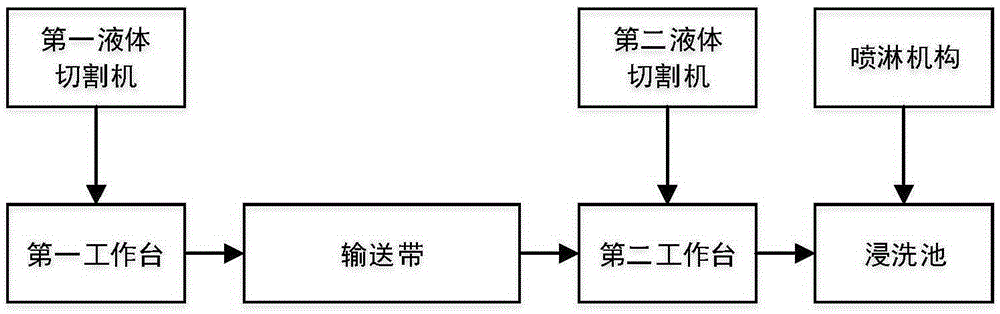

[0099] As a specific implementation of the high-pressure liquid cutting system provided in Embodiment 2 of the present invention, in the high-pressure liquid cutting system provided in Embodiment 3 of the present invention, the rinsing device includes a spray mechanism, a dipping pool,

[0100] The spray mechanism is used to spray the immersion liquid to the secondary dismantling objects,

[0101] The immersion tank is used to soak and contain the secondary dismantling materials.

[0102] Wherein, the soaking liquid is an alkaline solution.

[0103] Wherein, the alkaline solution is an aqueous solution of one or more solutes selected from sodium carbonate, sodium bicarbonate, calcium hydroxide, and sodium hydroxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com