A coal yard mechanical moisture-proof and pressure-resistant cable

A mechanical and cable technology, applied in the field of mechanical moisture-proof and compression-resistant cables in coal yard, can solve problems such as limited strength, moisture-damaged cables, damaged and exposed cables, etc., to achieve the effect of improving strength, improving tensile performance, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

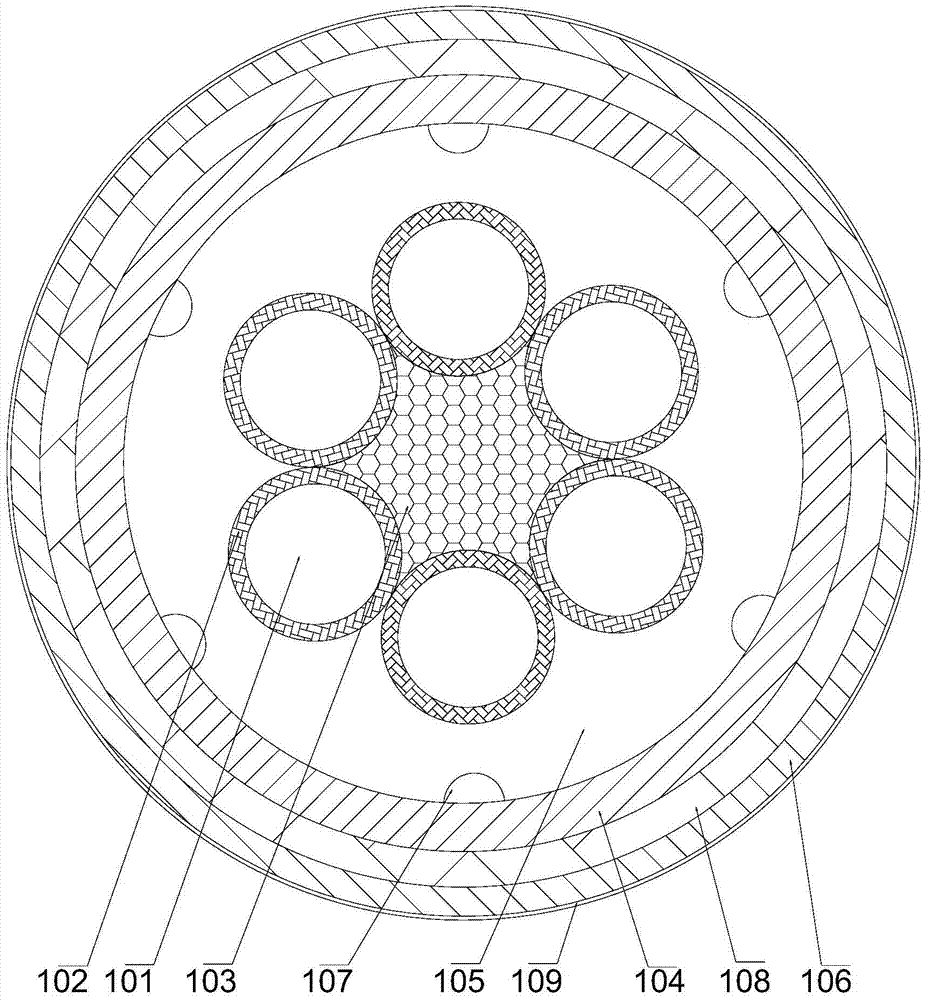

[0018] Such as figure 1 As shown, a coal yard mechanical moisture-proof and pressure-resistant cable includes at least three aluminum alloy conductors 101 and an insulating layer 102 arranged outside the aluminum alloy conductors 101. Above, an eyelet layer 104 is arranged outside the aluminum alloy wire 101, a rubber cushion layer 105 is arranged inside the eyelet layer 104, and a helical row is arranged on the inner wall of the rubber cushion layer 105. The groove of the cloth, the outer wall of the insulating layer 102 is attached to the inner side of the groove, the outer insulating layer 106 is arranged outside the metal ring layer 104, and the outer wall of the rubber cushion layer 105 is arranged There are concave structures 107 arranged in a spiral direction, and sponges are filled inside the concave structures 107, and the spiral direction of the concave structures 107 is opposite to that of the grooves.

[0019] When the present invention is subjected to external ex...

Embodiment 2

[0021] In order to improve the moisture-proof performance of the overall structure, in this embodiment, on the basis of Embodiment 1, preferably, a bamboo charcoal layer 108 is sheathed outside the eyelet layer 104 . By using the bamboo charcoal layer, it can absorb external moisture. Since the bamboo charcoal has a reversible moisture absorption effect, after a period of use, the moisture on the corresponding parts of the bamboo charcoal can be volatilized by drying.

[0022] In this embodiment, preferably, the eyelet layer 104 is a sheet metal strip wound helically on the outer wall of the rubber cushion layer 105 . By adopting a spiral winding manner, the production of the eyelet layers can be facilitated, and at the same time, the strength of the eyelet layers can be enhanced by covering and winding each other.

[0023] In order to improve the tensile performance of the cable, in this embodiment, preferably, the helical winding direction of the eyelet layer 104 is opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com