Radar monitoring method and device for long-term security risk of chemical equipment

A long-term technology with operational safety risks, applied to instruments, character and pattern recognition, computer components, etc., can solve problems such as inability to accurately and effectively monitor abnormal working conditions in chemical processes, so as to reasonably avoid adverse risk events and ensure safety Reliable operation and the effect of eliminating the root cause of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

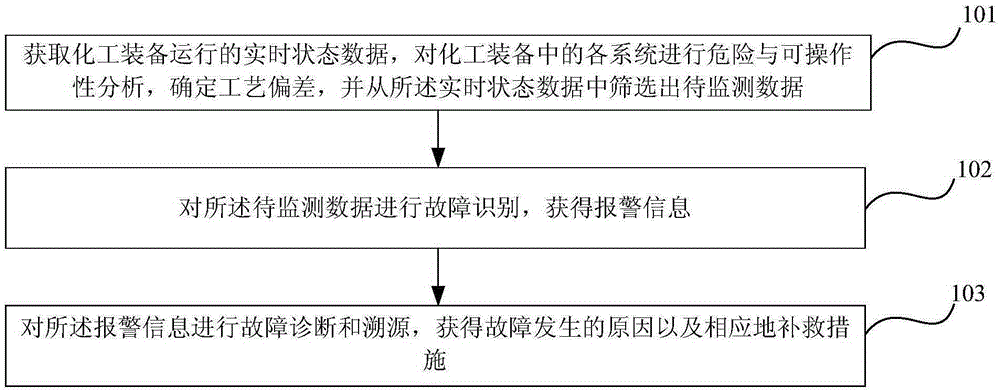

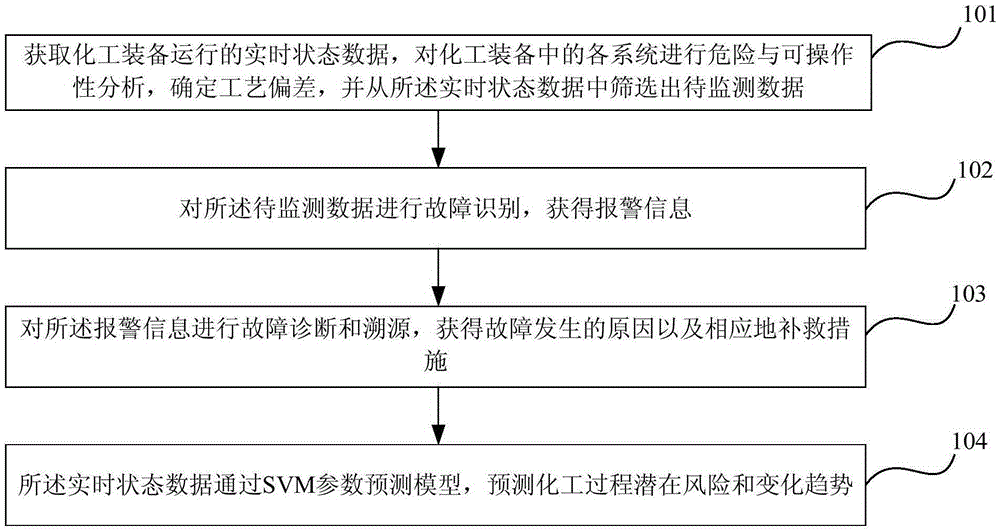

[0042] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

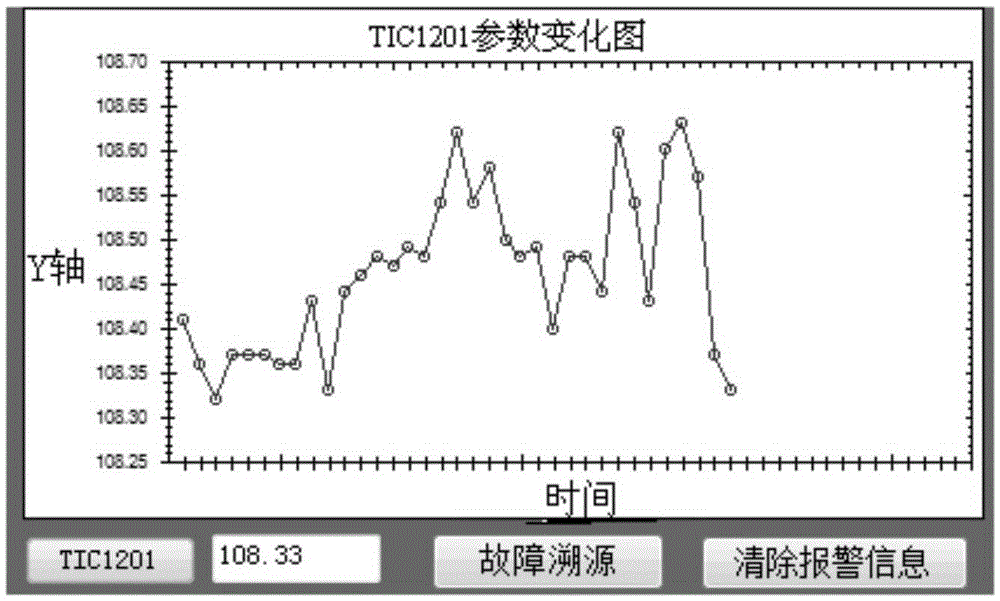

[0043] The working principle of this technical solution: This technical solution first combines the enterprise distributed control system and production information management system, adopts OPC technology, conducts research on data acquisition topology and interface with the Internet of Things network, obtains real-time status data of device operation, and Store data into SQL database in real time. Carry out risk and operability analysis on each system in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com