Feeding apparatus for industrial production line

A feeding device and production line technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems of large working noise, large energy consumption, and large volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

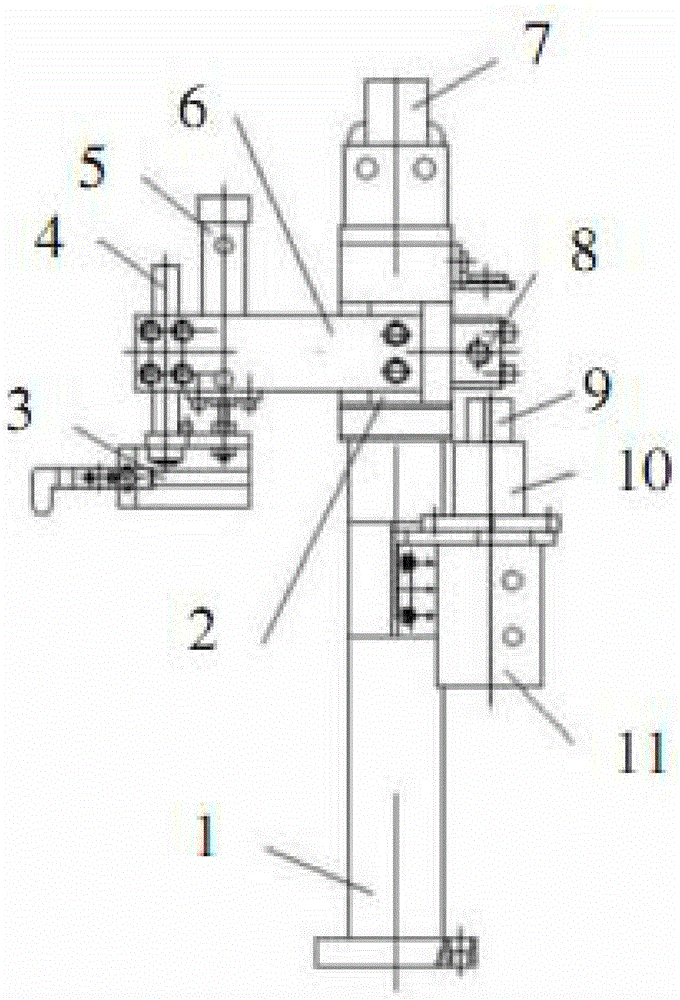

[0020] Fix the cylindrical base 1 on the ground, and the hydraulic cylinder 11 is installed on the cylindrical base sleeve, which is designed in the middle of the cylindrical base 1, as shown in the figure, the cylindrical base sleeve can rotate around the cylindrical base 1 , and can be fixed at any position, the positioning shaft 9 is connected to the top of the hydraulic cylinder 11, and the cylindrical sleeve 10 is installed on the positioning shaft 9. The height of the positioning shaft 9 can be adjusted by a hydraulic cylinder 11. The rotating rod 6 is installed on the rotating shaft 2, and the baffle plate 8 is fixed to the rotating rod 6, and performs circular motion together with the rotating rod 6. There is a slot at the end of the rotating rod 6, which is used to install the telescopic hydraulic cylinder 5, and the hydraulic cylinder 3 is installed on the telescopic hydraulic cylinder 5. As can be seen from the figure, the feeding plate is fixed on the extension sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com