Boiler roof expansion joint sealing device

A technology for expansion joints and corrugated expansion joints is applied in the field of boiler ceiling expansion joint sealing devices, which can solve the problems of affecting the safe operation of the heating surface and being easy to be pulled and cracked, and achieve the effects of simple structure, convenient workshop processing, and convenient on-site construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

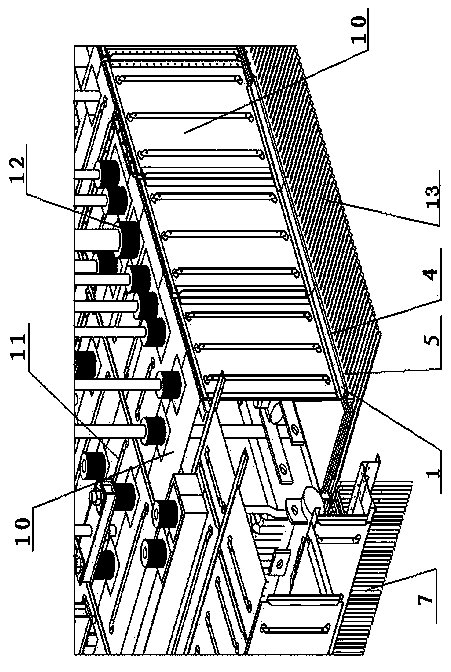

[0019] A boiler ceiling expansion joint sealing device, which consists of: ceiling pipe 13, guard plate 10, comb plate 4, corrugated expansion joint 1, circular expansion joint 12, pressure plate and ceramic fiber paper 3, the connection form is divided into ceiling film Type wall, surrounding membrane type wall, pipe 9 passing through furnace roof and suspender 8 are connected with the guard plate, and the ceiling membrane type wall and surrounding membrane type wall are connected with the guard plate by The comb-shaped plate is welded on the ceiling pipe and the water-cooled wall 7, the corrugated expansion joint is added between the guard plate and the comb-shaped plate, and the comb-shaped plate and the The ceramic fiber paper is placed between the corrugated expansion joints, and the corrugated expansion joints are welded to the guard plate.

Embodiment 2

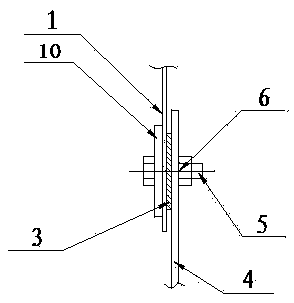

[0021] According to the boiler ceiling expansion joint sealing device described in Example 1, the ceiling membrane wall and surrounding membrane walls are connected to the guard plate, which is a ceiling metal inner guard plate covering the header and pipe joints Solder connection is used between them.

Embodiment 3

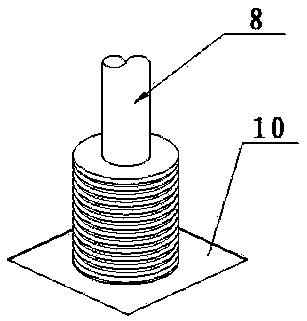

[0023] According to the boiler ceiling expansion joint sealing device described in embodiment 1 or 2, the pipe connection through the furnace roof adopts the method of adding the circular expansion joint, that is, the pipe passes through the circular expansion joint , and one end of the circular expansion joint is welded to the guard plate, and the other end is welded to the pre-welded part of the pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com