Device and method for conveying bobbins

A bobbin and bobbin technology, which is applied in the field of bobbin conveying devices, can solve the problems of complex mechanical structure and large space occupation of bobbins conveyed by horizontal steel belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0015] The present invention solves the deficiencies of the prior art and provides a bobbin conveying device and method. The device and method enable the spinning frame to be equipped with only one set of bobbin arranging device and full bobbin lifting device, which saves mechanical space and is structurally Also becomes simple.

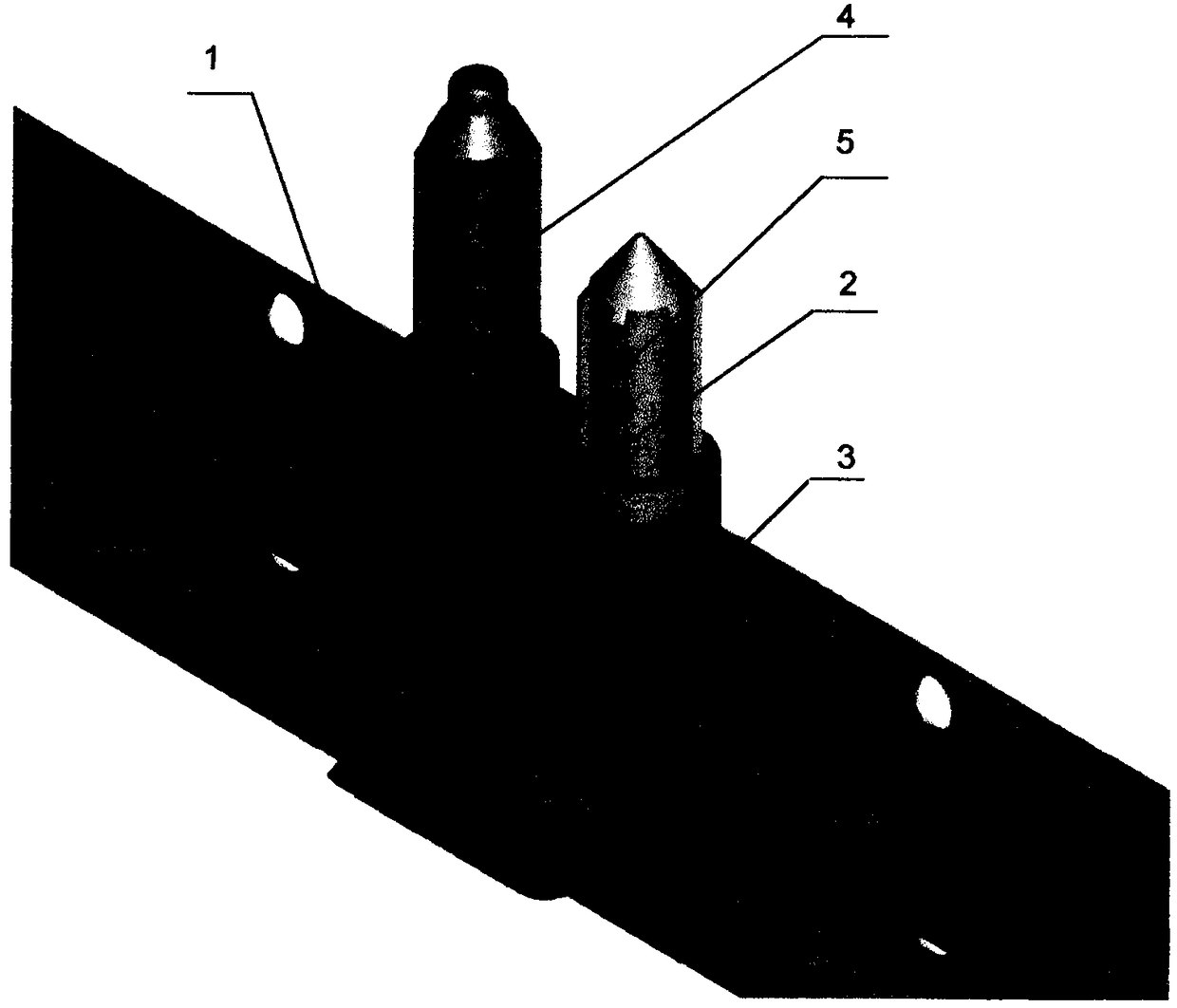

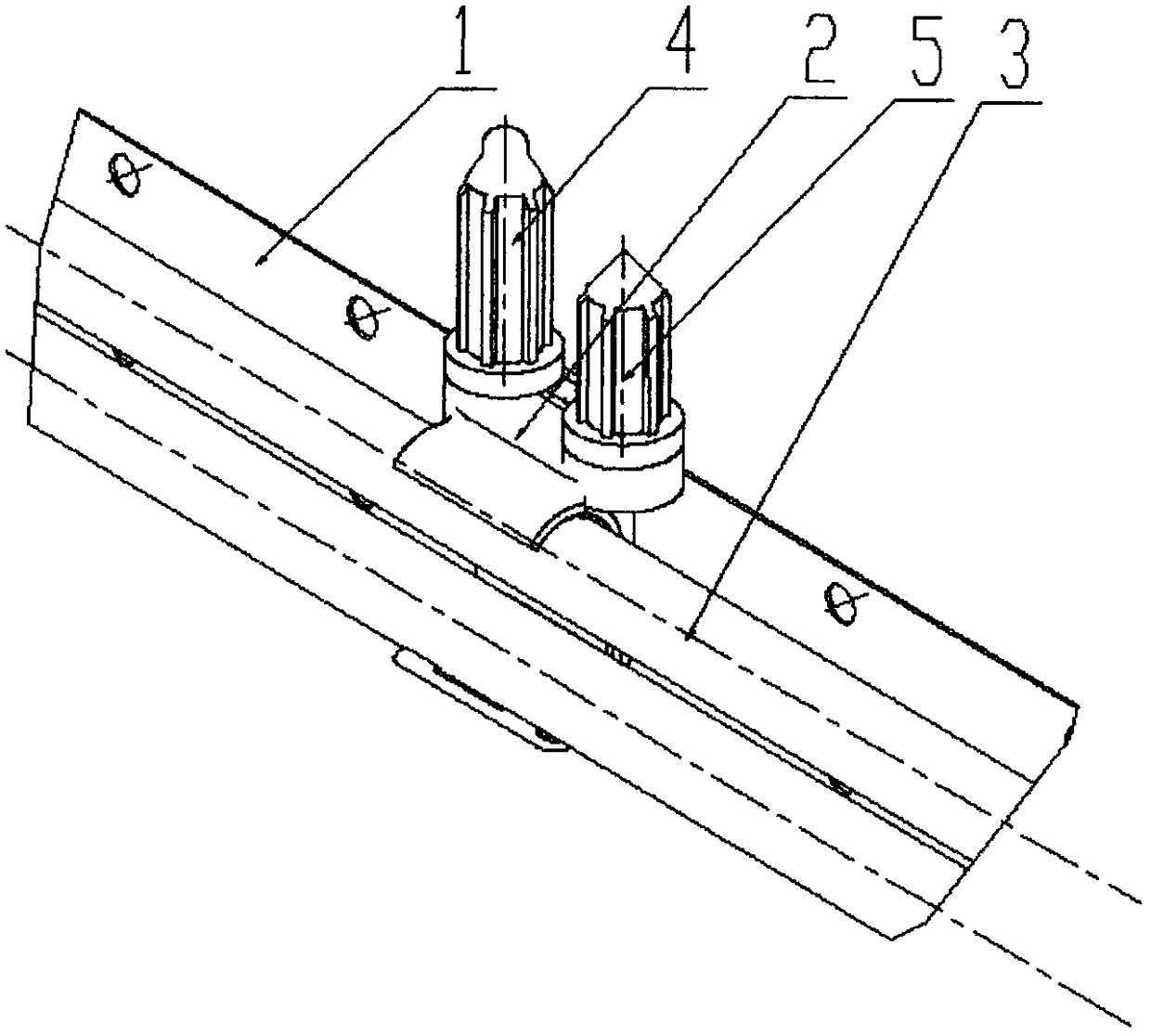

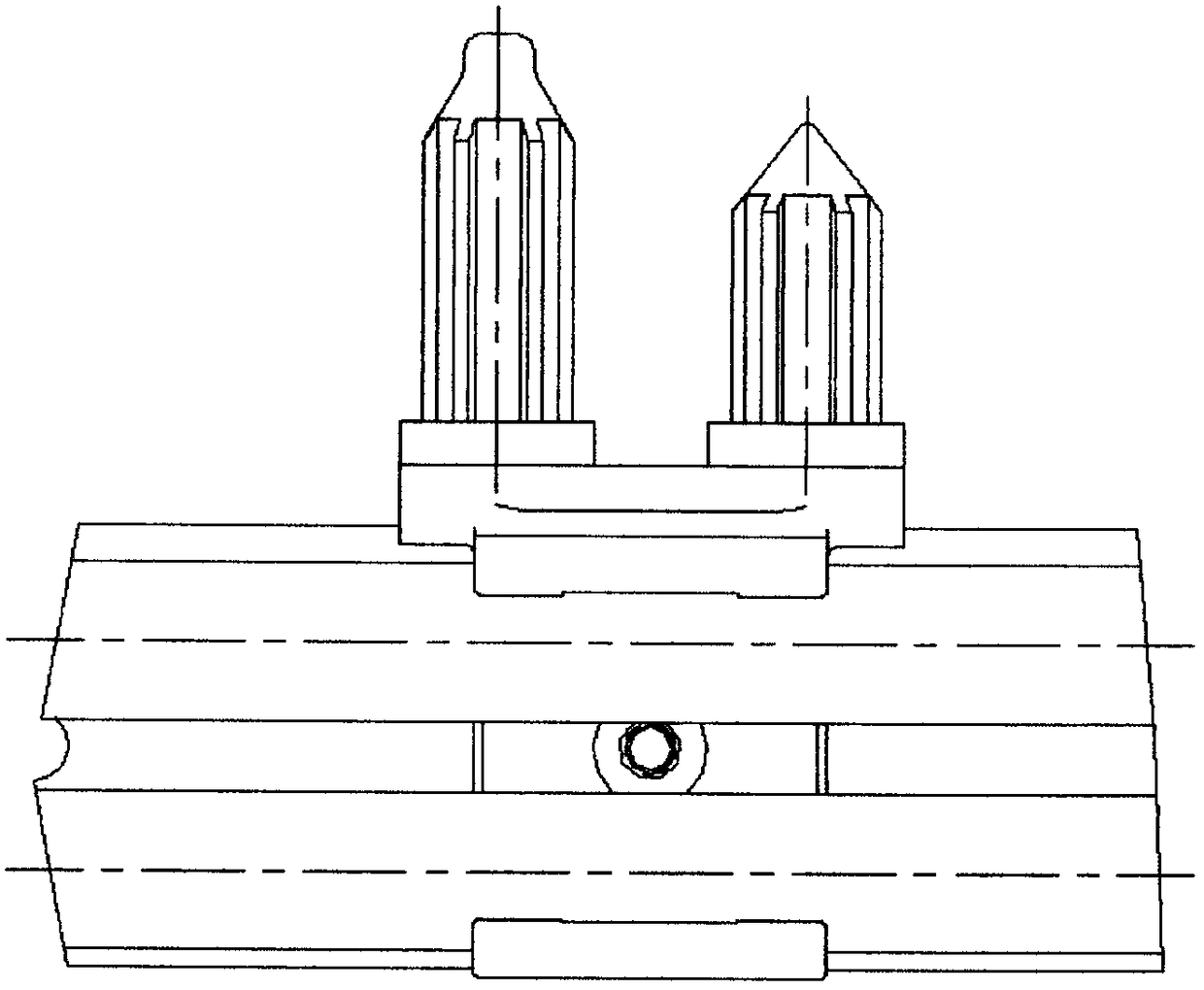

[0016] figure 1 It is a three-dimensional schematic diagram of a bobbin conveying device and method provided in an embodiment of the present invention. Such as figure 1 As shown, a device and method for conveying bobbins, said device and method comprising: a steel belt (1), a double-ended pipe bolt seat (2), a guide rail (3), a first pipe bolt (4), a second pipe bolt Bolt (5); the guide rail (3) is provided with a vertical steel strip (1) and a double-head pipe bolt seat (2).

[0017] Spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com