Support roller bearing of high-accuracy wide and thick plate straightening machine

A plate leveling machine, high-precision technology, applied in the field of bearings, can solve the problems that the leveling machine bearing, supporting outer ring and rotating shaft affect the production quality of precision plates, the backing bearing cannot be assembled with high precision, and the use and installation are cumbersome. The effect of saving mechanical space, compact structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof.

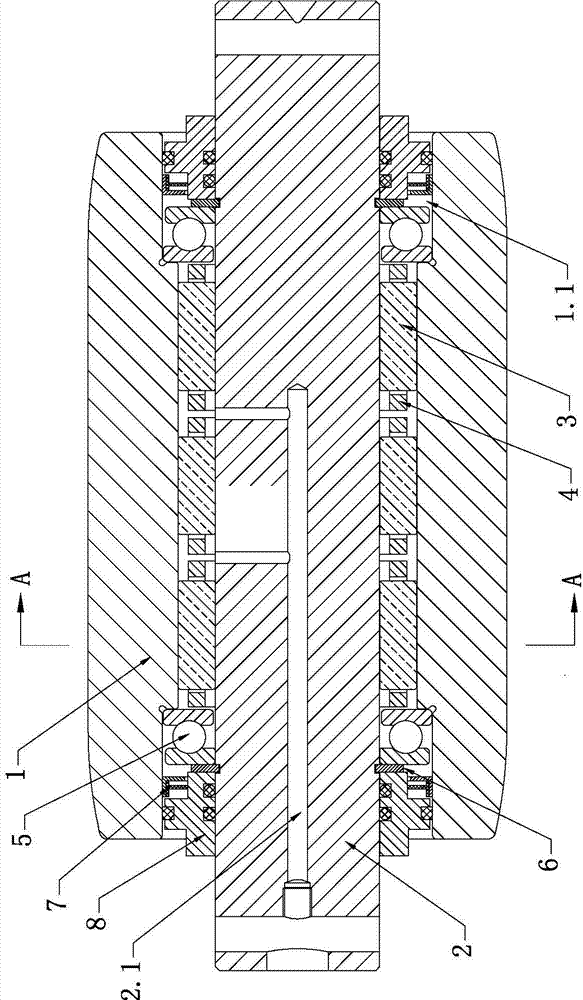

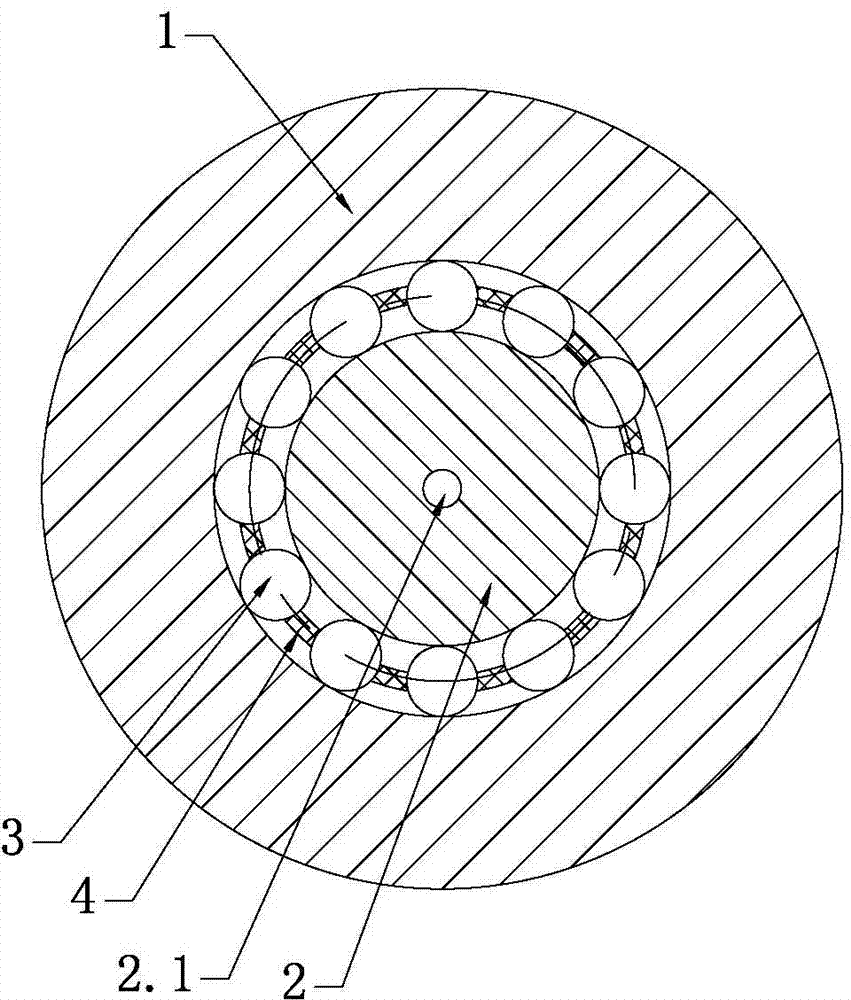

[0009] Such as figure 1 and figure 2 As shown, the high-precision wide and thick plate leveler support roller bearing is characterized in that it includes a support outer ring 1, a rotating shaft 2, a needle roller 3, a needle roller cage 4, a thrust ball bearing 5, a retaining ring 6, a sealing ring 7 and Dust-proof ring 8; a notch 1.1 is provided on the inner side of the two ports of the supporting outer ring 1, the rotating shaft 2 is set in the supporting outer ring 1, and three needle roller cages 4 are arranged on the rotating shaft 2, and each needle roller holds A number of needle rollers 3 are provided on the frame 4; a thrust ball bearing 5 is provided in the notch 1.1 of the supporting outer ring 1, and a retaining ring is arranged on the rotating shaft 2 outside each thrust ball bearing 5 from inside to outside in sequence 6. The sealing ring 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com