Grass impurity removing machine for wool

A wool and miscellaneous machine technology, applied in the direction of animal fiber impurity remover, etc., can solve the problems of increasing subsequent processes, lack of wool weeding equipment, difficulties, etc., and achieve the effect of reducing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

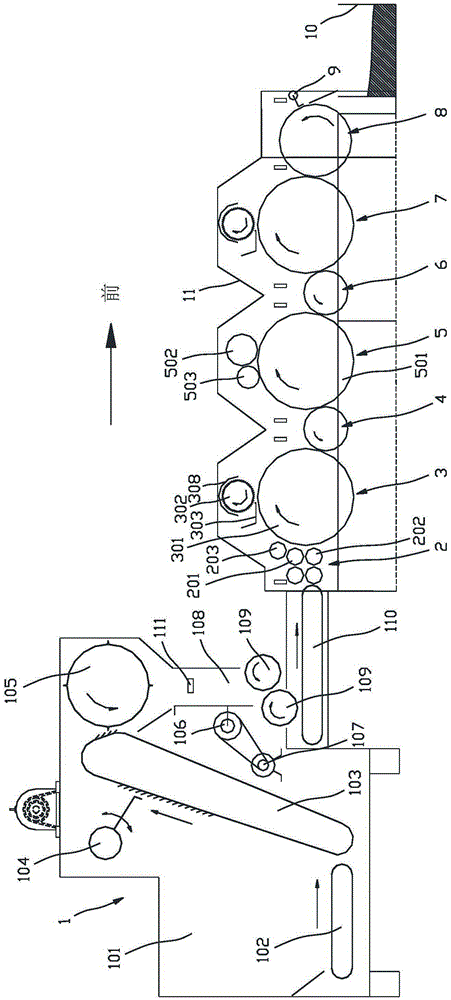

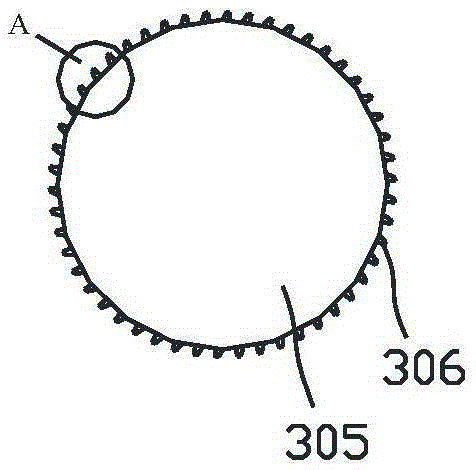

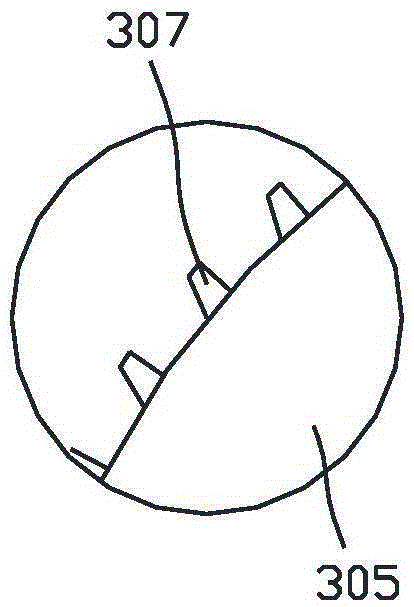

[0024] combine figure 1 As shown, a wool weeding machine includes a feeding mechanism 2, a first weeding mechanism 3, a No. 1 transfer roller 4, an opening mechanism 5, a No. 2 transfer roller 6, and a second weeding mechanism arranged sequentially from back to front. 7. Doffer 8 and stripping mechanism 9.

[0025] Behind the feeding mechanism 2, a vibrating volumetric wool feeding machine 1 is arranged. specific,

[0026] The vibrating volumetric wool feeding machine 1 comprises a wool feeding box 101, a bottom flat curtain 102, an oblique nail curtain 103, an even rake 104, a stripping roller 105, a vibrating plate 106, a vibrating plate motor 107, a volume box 108, a pair of pressing Hair roller 109 and conveying flat curtain 110.

[0027] The bottom flat curtain 102 is located at the bottom of the rear side of the hair feeding box 101, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com