Application of hyperbranched poly(amide amine)s in plastic processing

A polyamidoamine and amino-terminated hyperbranching technology, which is applied in the field of plastic processing aids, can solve the problems of limited application and poor thermal stability of plastic processing, and achieves the advantages of enhanced melt fluidity, easy extrusion into film, and reduced processing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

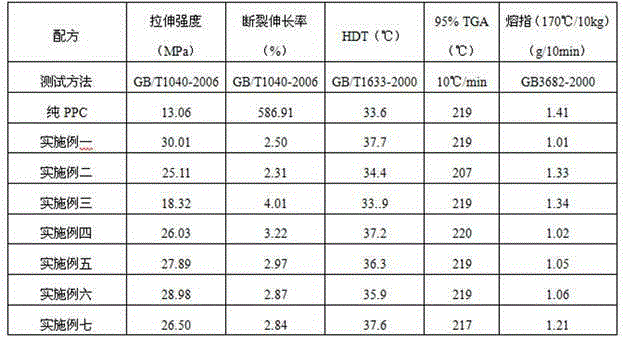

Examples

Embodiment 1

[0020] Mix 0.5 parts by weight of amino-terminated hyperbranched polyamidoamine and 100 parts by weight of PPC uniformly, extrude, granulate, and dry to obtain a modified PPC product.

Embodiment 2

[0022] Mix 5 parts by weight of amino-terminated hyperbranched polyamidoamine and 100 parts by weight of PPC uniformly, extrude, granulate, and dry to obtain a modified PPC product.

Embodiment 3

[0024] Dry the amino-terminated hyperbranched polyamidoamine for later use; take 100 parts by weight of PPC and 0.1 part by weight of the above-mentioned amino-terminated hyperbranched polyamidoamine, and mix them to obtain a mixture for later use; raise the temperature of the twin-screw extruder to 160°C, After preheating for 1 hour, put the above mixture into a twin-screw extruder, extrude and granulate; dry the granules at 50°C for 1 hour to obtain a modified PPC product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com