Energy-saving and environment-friendly production process of isobutyl lactate

An energy-saving and environmentally-friendly technology of isooctyl lactate, which is applied in the preparation of ester groups and hydroxyl groups, organic chemistry, etc., can solve the problems of high corrosion of equipment, environmental pollution of waste water, and influence on the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

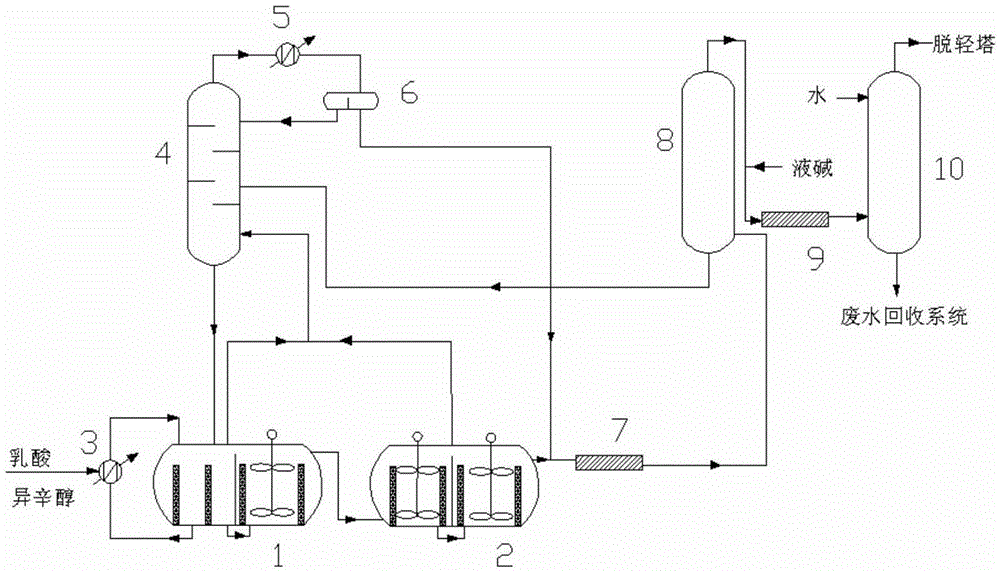

[0021] Such as figure 1 As shown, the device of the production process of isooctyl lactate of the present invention adopts continuous feeding, isooctanol and lactic acid are mixed according to the alkyd molar ratio of 1.8:1 and then thrown into the heater 3, and flow to the first reaction kettle after heating 1, the total flow rate is 1000L / h, when the conversion rate of lactic acid in the first reactor 1 reaches about 60%, it can be discharged into the second reactor 2, when the conversion rate of lactic acid in the second reactor 2 reaches about 85% % can be discharged into the water washing mixer 7 to fully mix with water, then flow into the water washing tower 8 and carry out standing stratification, the top oil phase of the water washing tower 8 is mixed with the liquid caustic soda through the alkali washing mixer 9, and then Go into the alkali washing tower 10 and stratify. The water phase at the bottom of the water washing tower 8 enters the middle part of the dehydra...

Embodiment 2

[0023] Such as figure 1 As shown, the device of the production process of isooctyl lactate of the present invention adopts continuous feeding, isooctanol and lactic acid are mixed according to the alkyd molar ratio of 1.8:1 and then thrown into the heater 3, and flow to the first reaction kettle after heating 1, the total flow rate is 1500L / h, when the conversion rate of lactic acid in the first reactor 1 reaches about 60%, it can be discharged into the second reactor 2, when the conversion rate of lactic acid in the second reactor 2 reaches about 85% % can be discharged into the water washing mixer 7 to fully mix with water, then flow into the water washing tower 8 and carry out standing stratification, the top oil phase of the water washing tower 8 is mixed with the liquid caustic soda through the alkali washing mixer 9, and then Go into the alkali washing tower 10 and stratify. The water phase at the bottom of the water washing tower 8 enters the middle part of the dehydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com