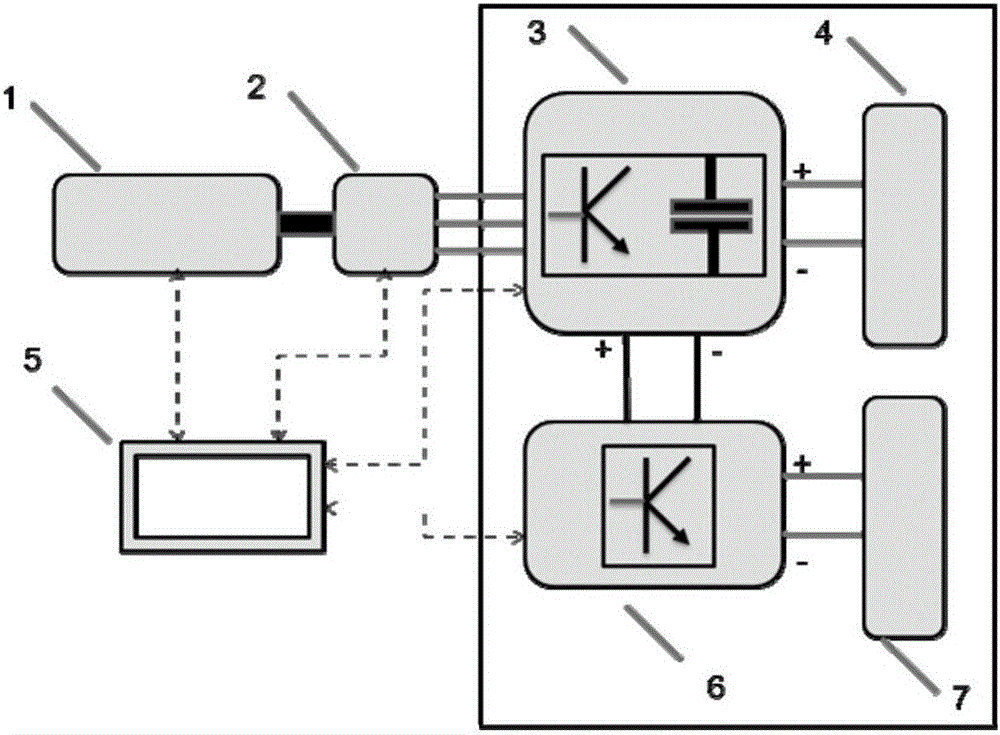

An energy feedback system and method for an electric drive automatic transmission

A technology of automatic transmission and energy feedback, applied in electric braking system, electric vehicle, electric energy management, etc., can solve the problems of high cost and complex structure, and achieve the effect of reducing cost and simplifying system structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

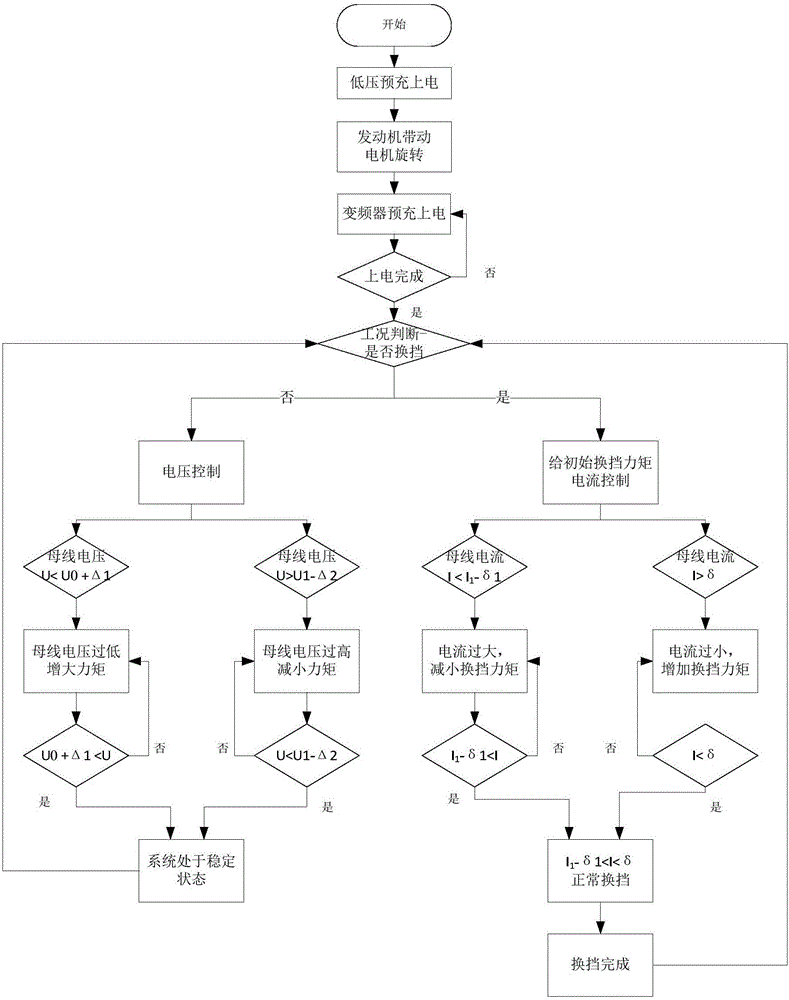

[0040] An energy feedback method for driving an automatic transmission, such as figure 2 As shown, it includes the following steps:

[0041] S1. Low-voltage pre-charging: Use the vehicle-mounted low-voltage DC power supply to perform low-voltage pre-charging on the capacitor of the inverter.

[0042] S2. Power on: The permanent magnet motor is driven and rotated by the engine, and the IGBT of the permanent magnet motor controller rectifies the three-phase alternating current at the permanent magnet motor end into direct current to charge the capacitor of the frequency converter, and the charging is controlled by controlling the rotational speed of the engine The process until the threshold voltage value of the permanent magnet motor controller is reached.

[0043] S3. Normal operation: After the inverter is powered on, it controls the permanent mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com