Spring-loaded screen

A spring type and screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of removal and screen filter effect, and achieve the effect that it is not easy to be cleaned and handled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

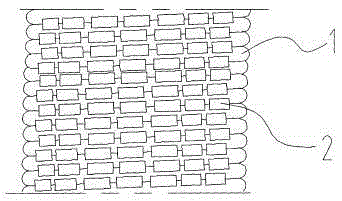

[0012] The sieve of the present invention can be made by winding a metal wire, metal strip, plastic strip or plastic wire into a compression spring type structure, and then processing the sieve hole 2 in the middle of the adjacent rib ring 1; It is also possible to set concave holes of the same specification on the corresponding two sides of a metal wire, metal strip, plastic strip or plastic wire respectively, and the distance between adjacent concave holes is equal, and then the metal wire, metal with concave holes Strips, plastic strips or plastic wires are wound into a compressed spring structure, and in the middle of adjacent rib rings 1, two concave holes can form a screen hole 2.

[0013] combine Figures 1 to 3 , the screen mesh of the present invention is made up of several rib rings 1, the ends and end tails of the two ends of the rib ring 1 are not connected, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com