Combined propeller cap for reducing rotating flow and hub vortex and enhancing propulsion efficiency

A propeller hub and propulsion efficiency technology, which is applied in the direction of rotating propellers and rotary propellers, can solve the problems of increasing manufacturing difficulty and increasing production costs, and achieve the effects of improving propulsion efficiency, low cost, and reducing hub vortex cavitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

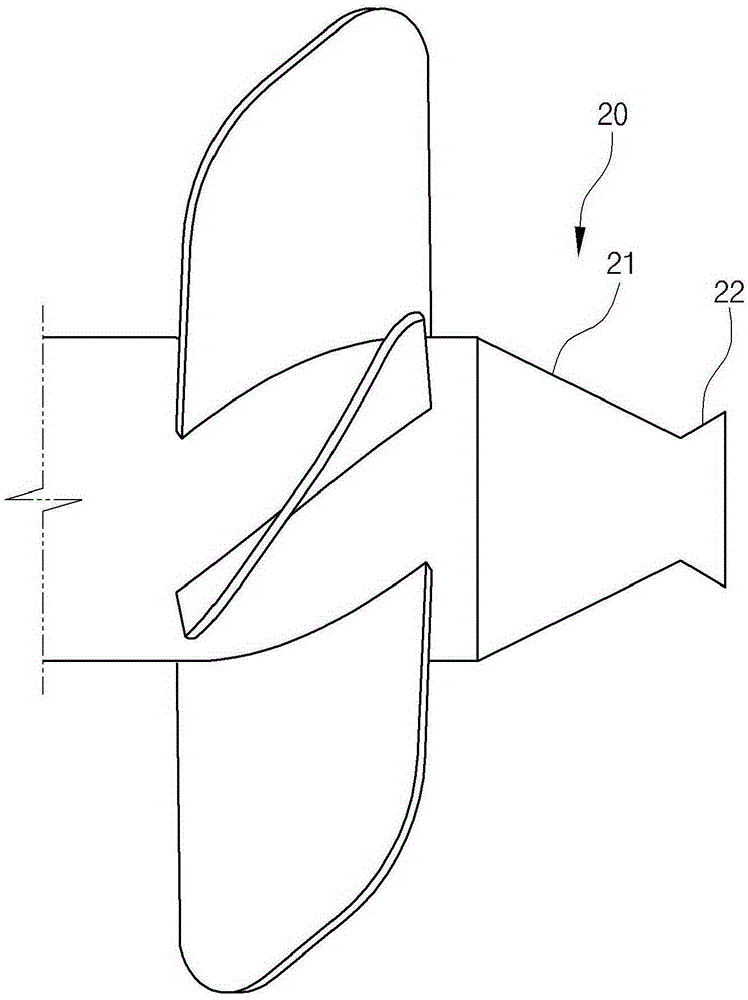

[0065] Specific embodiments of the composite propeller hub cap for reducing swirling flow and hub vortex and improving propulsion efficiency according to the present invention will be described in detail below with reference to the accompanying drawings.

[0066] It is stated in advance that the content described below is only an embodiment for implementing the present invention, and the present invention should not be limited to the content of the embodiment described below.

[0067] In order to simplify the description when describing the following embodiments of the present invention, the detailed description of the parts that are the same or similar to the prior art or can be easily understood and implemented by those skilled in the art will be omitted.

[0068] Meanwhile, in order to pursue simplification of description when describing the following embodiments of the present invention, the same or similar constituent elements are given the same symbol and detailed descrip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com