Workboat moving in hydraulic stay bar mode

A workboat, hydraulic technology, applied in the direction of propulsion components, ship construction, ship propulsion, etc., can solve problems such as insufficient propulsion force and obstacle-surmounting ability, difficulty in normal work of crawler-type walking mechanism, and no good solution, etc., to achieve improvement The effect of promoting efficiency and good obstacle-surpassing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

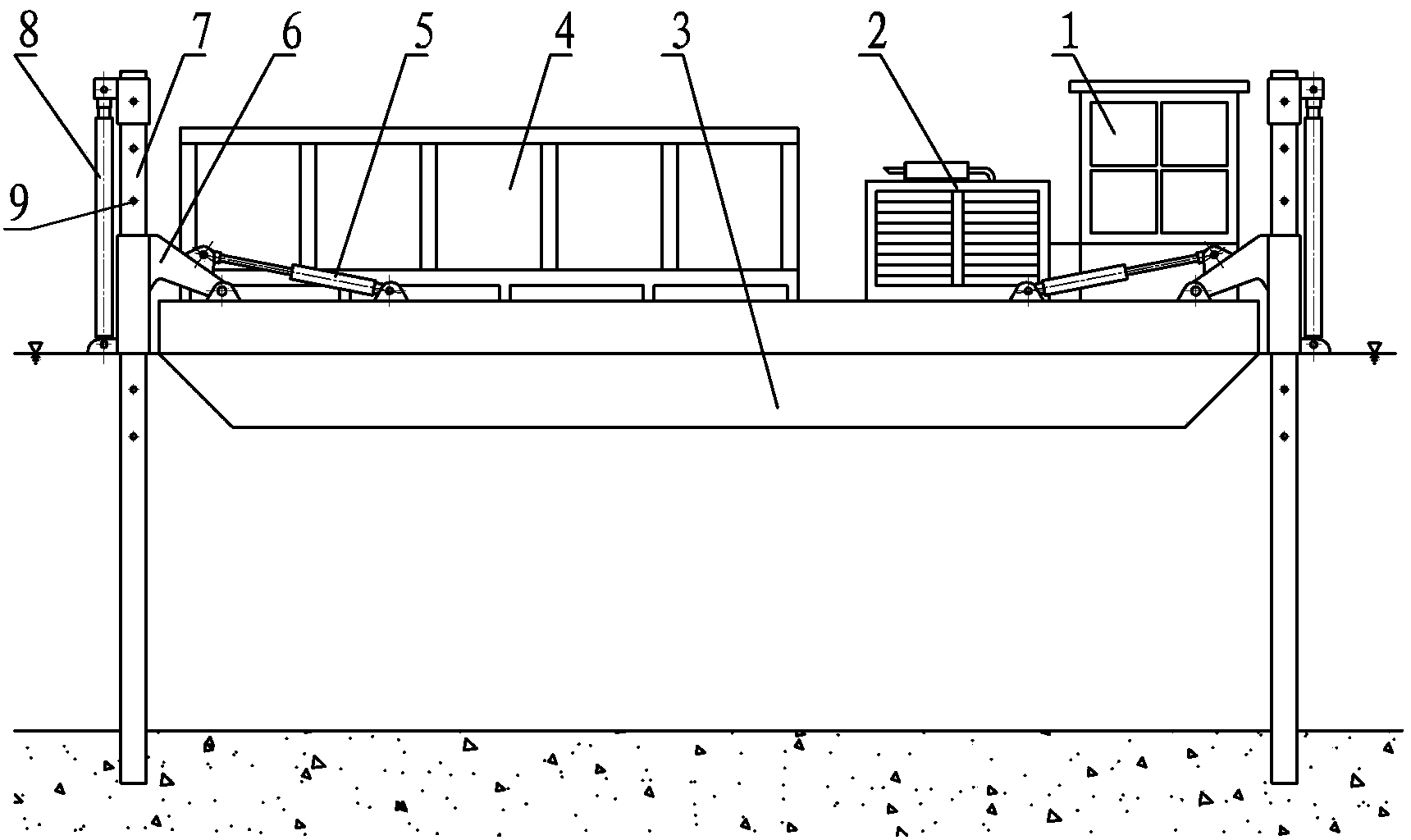

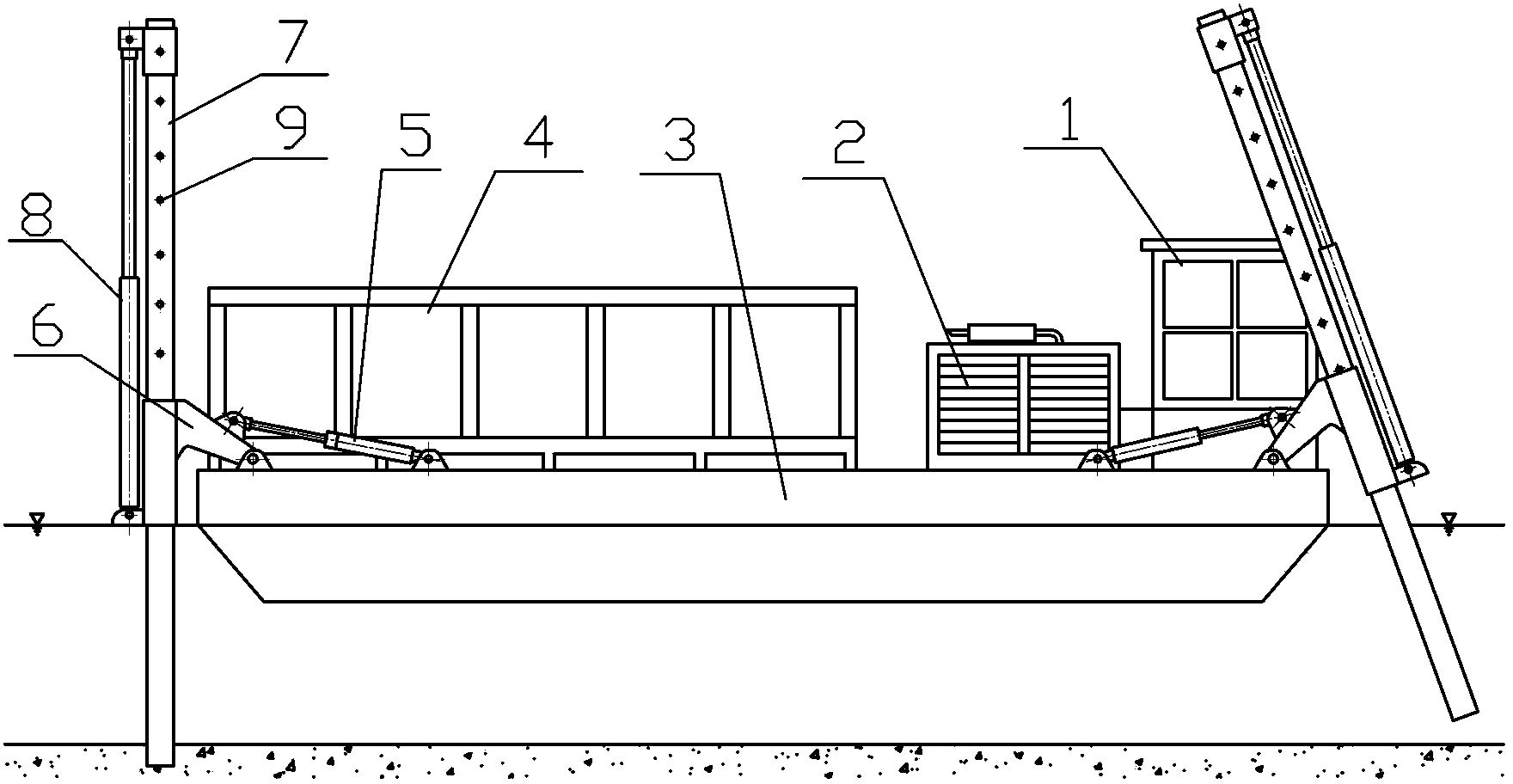

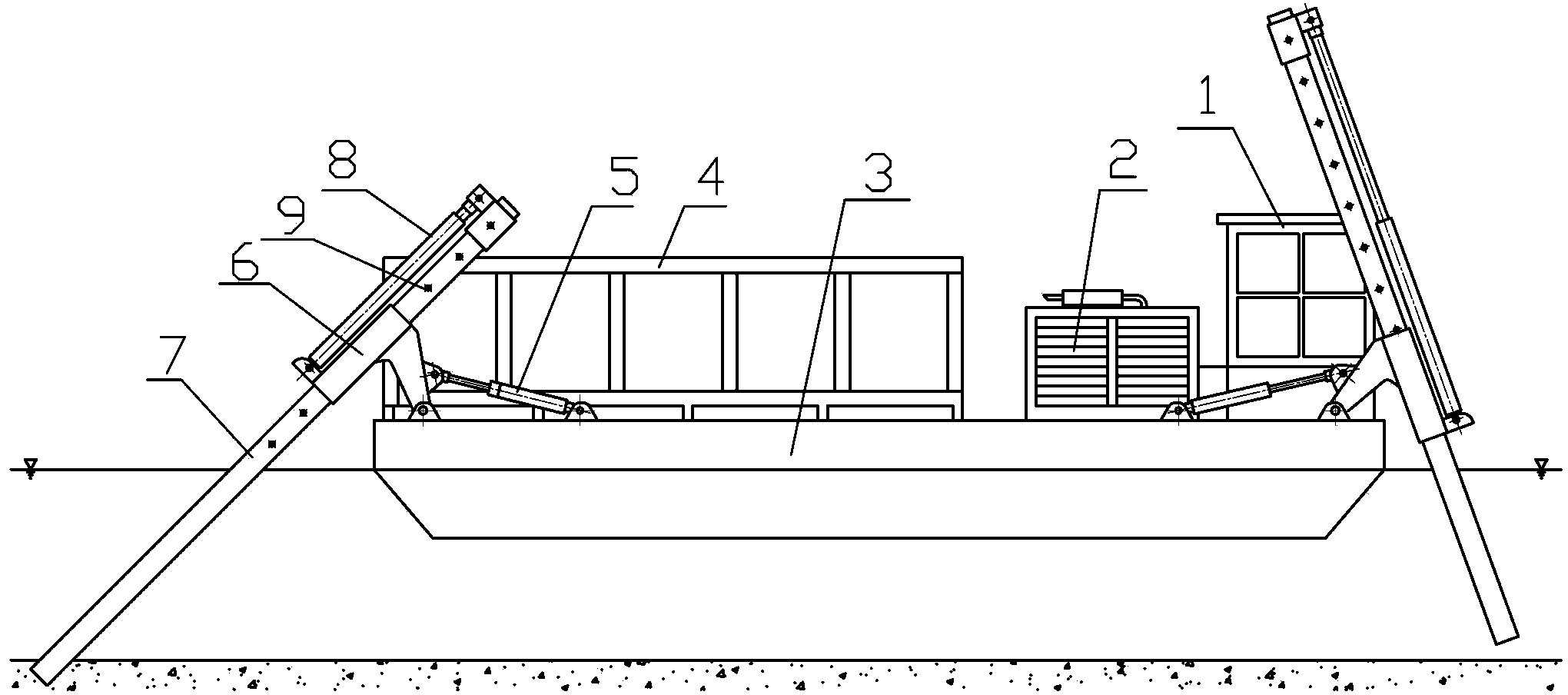

[0022] Refer to the attached figure 1 to attach Figure 6 A hydraulic strut-type traveling workboat of the present invention will be described in detail below.

[0023] A hydraulic strut type working boat of the present invention, its structure includes a hull 3, a control room 1 and an operating device 4, the operating device 4 and the control room 1 are respectively arranged on the upper part of the hull 3, and the hull The front and rear sides of 3 are respectively equipped with hydraulic strut devices, and the hydraulic strut device and the control room 1 are respectively connected with the hydraulic pump station 2, the power of the hydraulic strut device comes from the hydraulic pump station, and the The control room can manipulate the power output of the hydraulic pump station, and the hydraulic pump station 2 is arranged on the upper part of the hull 3 .

[0024] The hydraulic strut device includes a strut 7, a grip arm 6, a swing cylinder 5 and a lift cylinder 8, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com