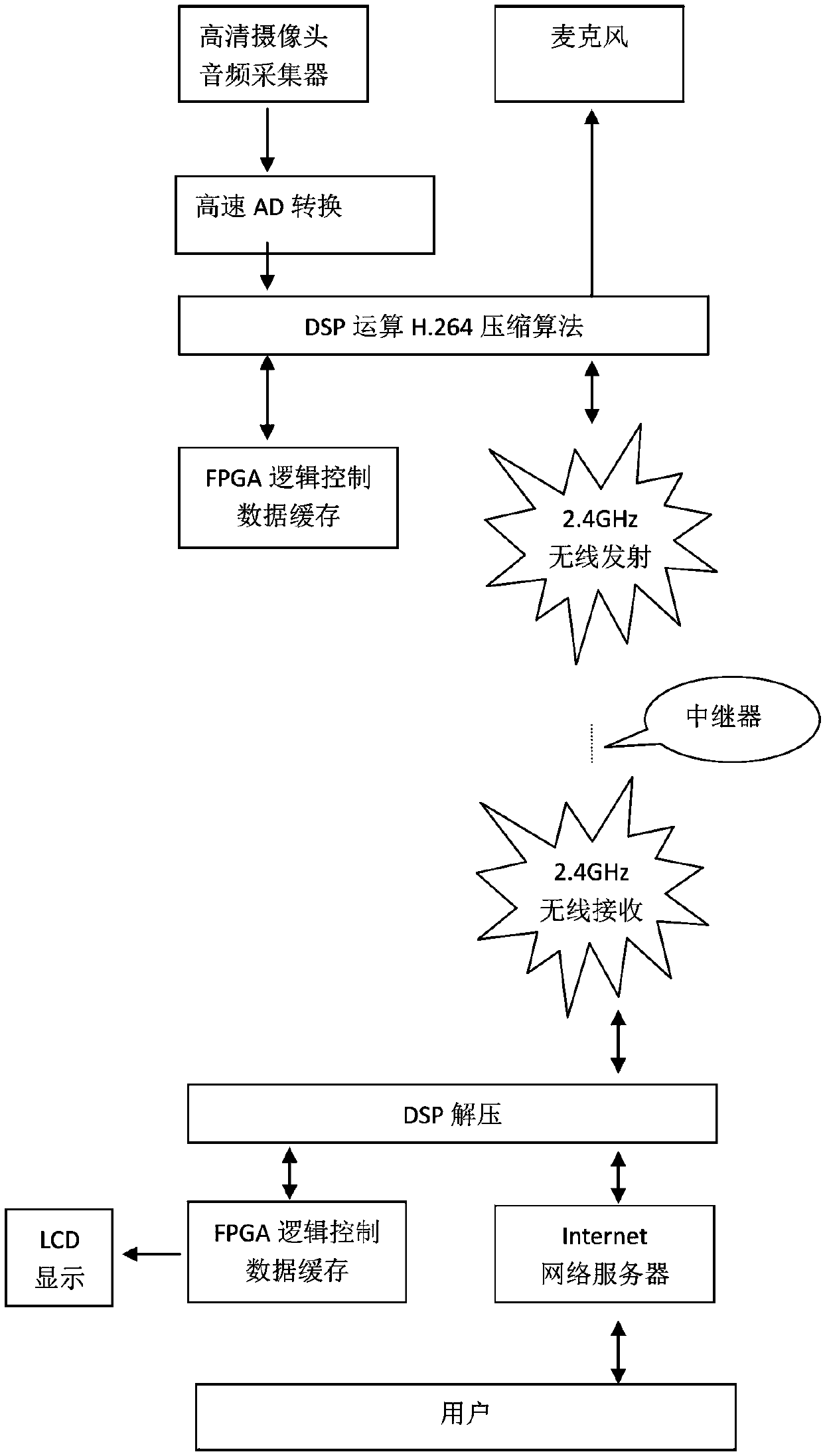

Remote inspection system

An inspection system and remote technology, applied in the field of remote inspection systems, can solve problems such as signal distortion, missed detection and wrong detection, and difficulty in meeting resolution requirements, and achieve the effect of small environmental interference and preventing missed inspections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0021] The difference between embodiment 2 and embodiment 1 is that it also includes a detection alarm module, which includes a feature extraction module, a temperature detection module and an alarm device; the feature extraction module mainly performs preset image features Extract and process, and transmit the information to the alarm device. This module is mainly used to monitor the instrument dial. When the active pointer points to a specific area, the alarm device will issue an alarm. The alarm device is an alarm indicator light and an alarm buzzer; The temperature detection module includes an infrared temperature sensing probe and a temperature data processing sub-module. The infrared temperature sensing probe is responsible for detecting the temperature of the entire equipment to be inspected, and transmits the temperature data to the temperature data processing sub-module in real time. The temperature data processing sub-module and the alarm device When the temperature r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com