Flexible graphite alkene nanometer wall magnetic field detection device and preparation method

A graphene nano wall and detection device technology, which is applied in the measurement device, the size/direction of the magnetic field, and the use of permanent magnets for magnetic field measurement, etc., can solve the problems of low measurement accuracy, low sensitivity, poor stability, etc., and achieve high measurement accuracy , high sensitivity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

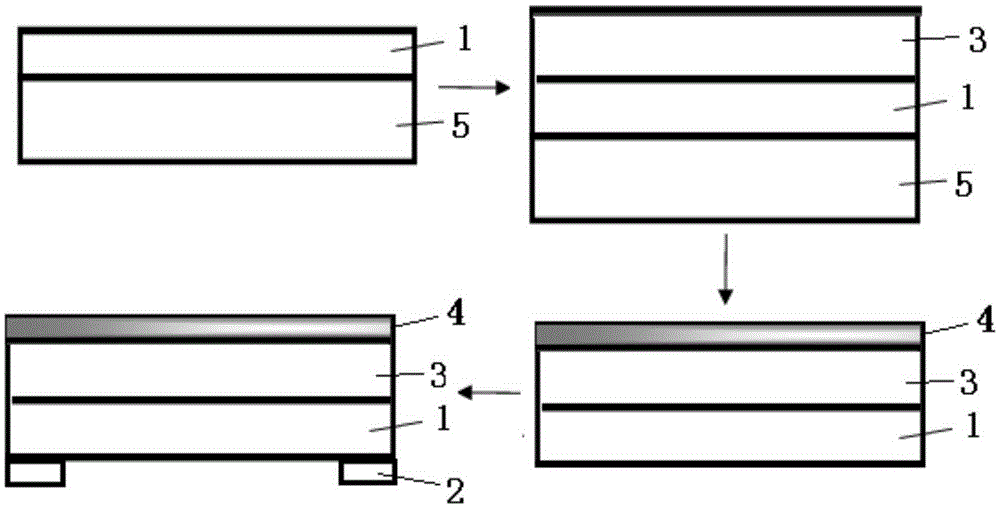

[0031] as per figure 1 The schematic flow chart of the preparation steps is shown to prepare the flexible graphene nano-wall magnetic field detection device, where 1 represents the graphene nano-wall film, 2 represents the parallel electrodes, 3 represents the flexible substrate, 4 represents the magnetic field sensing layer, and 5 represents the substrate.

[0032] Specific steps are as follows:

[0033] 1) Cleaning of the substrate: ultrasonically clean the copper foil 5 in acetone, ethanol and deionized water for 5 minutes respectively, and dry it with nitrogen gas for later use;

[0034] 2) Graphene growth: place the dried copper foil 5 in the vacuum chamber of the CVD system, and feed a mixed gas of hydrogen and methane with a volume ratio of 2:3 into the vacuum chamber at a temperature of 550°C and a pressure of 20Pa Under the conditions of growth for 30min, the graphene nano-wall 1 was obtained, and the graphene nano-wall was scanned by an electron microscope, and the ...

Embodiment 2

[0040] Prepare a flexible graphene nano-wall magnetic field detection device according to the schematic diagram of the preparation steps shown in Question 1. The specific steps are as follows:

[0041] 1) Substrate cleaning: place the quartz 5 in acetone, ethanol and deionized water for ultrasonic cleaning respectively for 5 minutes, and dry it with nitrogen for later use;

[0042] 2) Graphene growth: place the dried quartz in the vacuum chamber of the CVD system, and feed a mixture of hydrogen and methane with a volume ratio of 2:3 into the vacuum chamber at a temperature of 700°C and a pressure of 100Pa. Grow for 25 minutes to obtain graphene nanowall 1;

[0043] 3) Coating flexible substrate material: coating TPU3 on the surface layer of the graphene nanowall 1, and then curing in a vacuum oven at a temperature of 100°C for 1 hour;

[0044] 4) Coating the magnetic field sensing layer material: peeling off the graphene nanowall 1 from the substrate 5, and coating the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com