Ultrasonic self-focusing phased-array detecting device for butt weld of small diameter tubes

An ultrasonic phased array and butt weld technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of small space between pipes, inability to move detection, and many welding seams, etc., to achieve mass detection , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is further described in conjunction with the following examples.

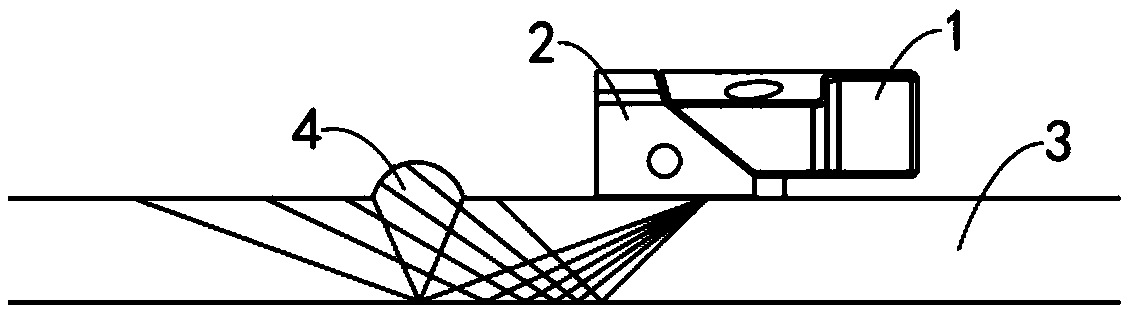

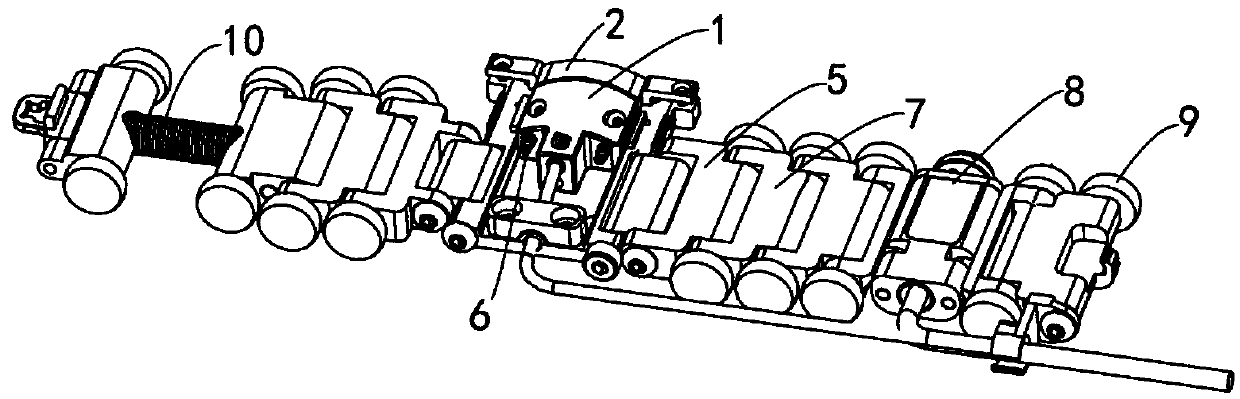

[0021] Ultrasonic self-focusing phased array testing device for small-diameter pipe butt welds, including ultrasonic phased array instrument, 60° shear wave wedge 2, 7.5Mhz self-focusing ultrasonic phased array probe 1, chain scanning frame 5, miniature encoder 8 and Water coupler.

[0022] The chain scanning frame 5 can be movably installed on the small diameter pipe 3 relative to the small diameter pipe 3, and the 60° shear wave wedge 2 and the 7.5Mhz self-focusing ultrasonic phased array probe 1 are connected to each other and fixed on the chain scanning rack 5.

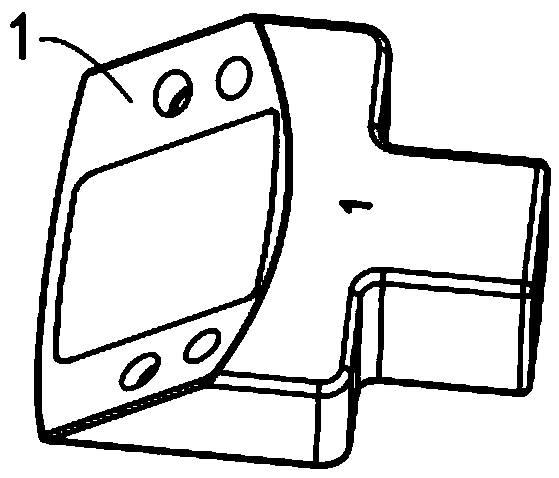

[0023] Such as figure 1 As shown, the surface of the 7.5Mhz self-focusing ultrasonic phased array probe 1 is a curved surface matching the junction of the 60° shear wave wedge 2, and the 7.5Mhz self-focusing ultrasonic phased array probe 1 is a curved surface array probe, The chip of the 7.5Mhz self-focusing ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com