Dynamometer with self-check function

A dynamometer and functional technology, applied in the field of dynamometers, can solve the problems that the dynamometer cannot be fixed, the detection test cannot be carried out, etc., and achieve the effects of easy observation and reading, simple structure and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

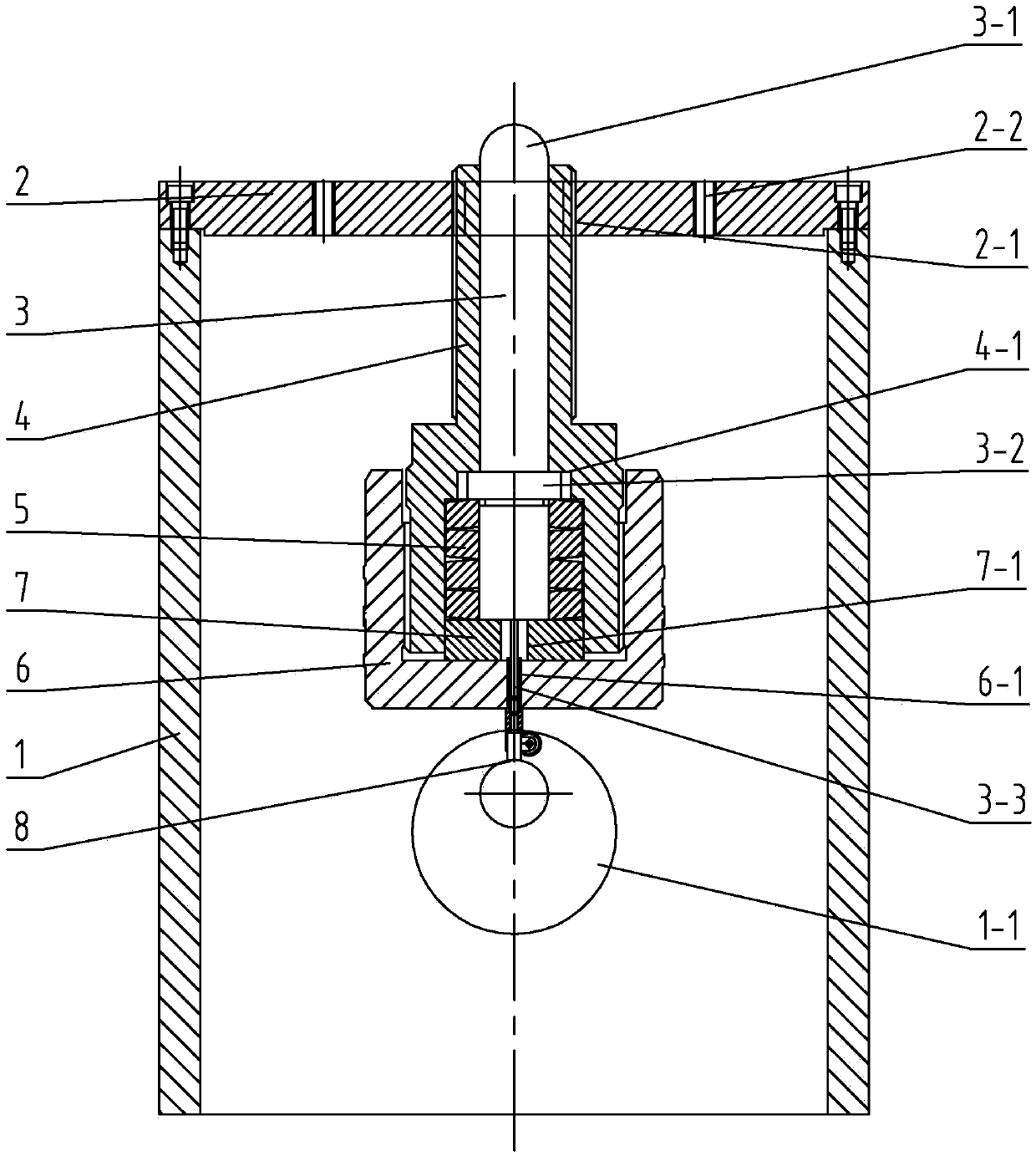

[0008] Specific implementation mode one: combine figure 1 Explain that a dynamometer with self-test function described in this embodiment includes an outer shell 1, an upper cover plate 2, a push rod 3, a sleeve 4, a spring leaf 5, a fixing seat 6, a bottom plate 7 and a dial indicator 8 , the outer casing 1 is a cylindrical body with openings at both ends, the upper end surface of the outer casing 1 is fixedly connected with an upper cover plate 2, the middle part of the upper cover plate 2 is provided with a first threaded through hole 2-1, and the sleeve 4 is arranged on In the outer shell 1, the upper end of the sleeve 4 is screwed into the first threaded through hole 2-1, the inside of the sleeve 4 is inserted with a push rod 3, and the inside of the lower end of the sleeve 4 is provided with a positioning groove 4-1, and the top The middle part of the rod 3 is provided with a boss 3-2, and the boss 3-2 is arranged at the bottom of the positioning groove 4-1, the outer si...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 Explain that the side wall of the upper end of the ejector rod 3 and the inner side wall of the upper end of the sleeve 4 in this embodiment are slidably connected in the vertical direction, and the side wall of the tail rod 3-3 is connected with the hole wall of the through hole 6-1 of the fixing seat in the vertical direction. Swipe to connect. Other compositions and connection methods are the same as those in Embodiment 1.

[0011] Such a design can ensure that the ejector rod 3 moves up and down in the vertical direction, and prevent the ejector rod 3 from tilting, thereby affecting the measurement effect.

specific Embodiment approach 3

[0012] Specific implementation mode three: combination figure 1 To illustrate, the lower end of the sleeve 4 in this embodiment is fixedly connected to the fixing seat 6 . Other compositions and connection modes are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com