A Diaphragm Pump Diaphragm Fatigue Testing Machine

A technology of fatigue testing machine and diaphragm pump, which is applied in the field of fatigue testing machine, can solve the problems of long time consumption and high power consumption, and achieve the effects of reducing power usage, improving efficiency and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

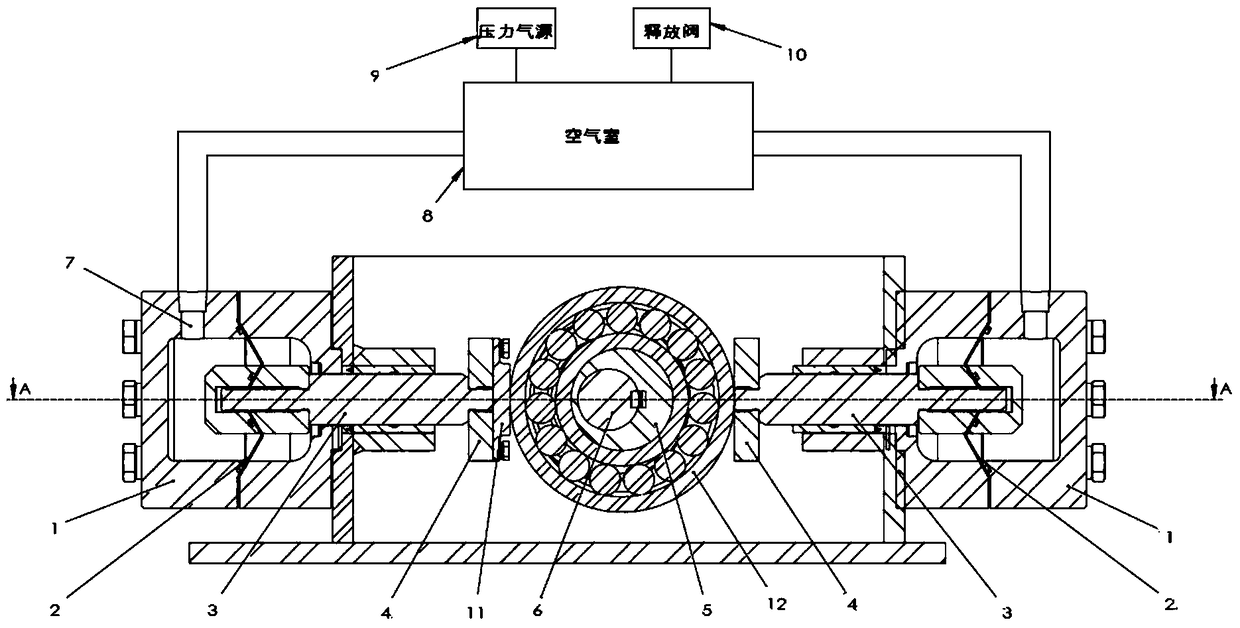

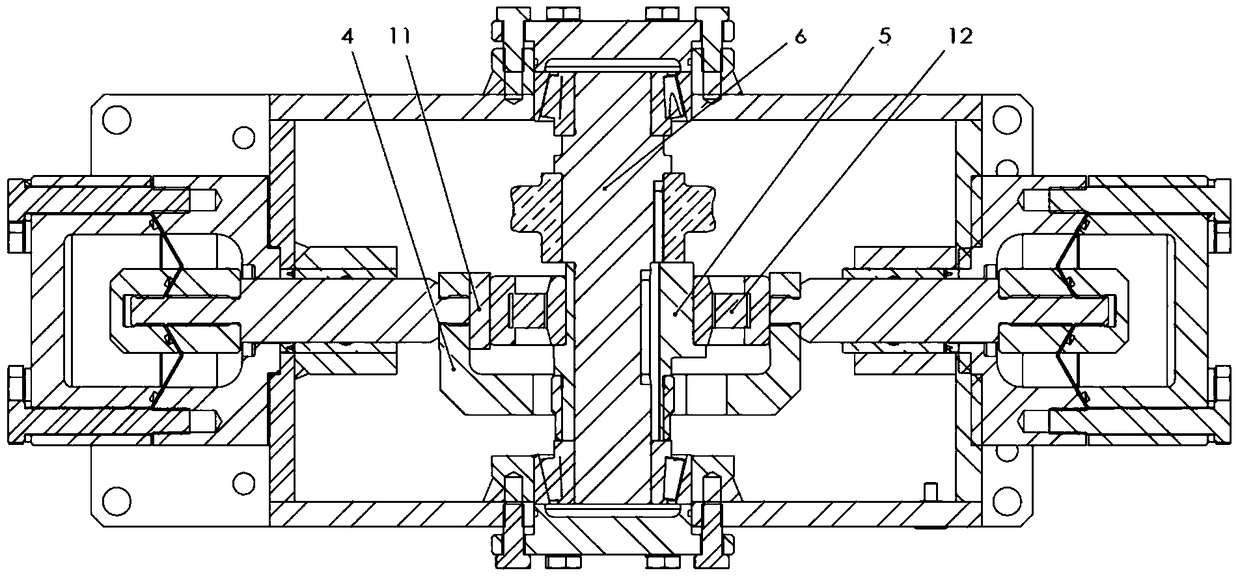

[0021] like figure 1 As shown in -2, a diaphragm fatigue testing machine for a diaphragm pump includes a drive unit, a linkage unit, a pump head 1 and a pressure control unit connected in sequence.

[0022] The drive unit includes an eccentric wheel 5 and a drive shaft 6. The drive shaft 6 is sleeved in the eccentric wheel 5. The outer edge of the eccentric wheel 5 is covered with a rolling bearing 12 to reduce friction loss. The drive shaft 6 The eccentric wheel 5 is driven to rotate under the drive of the motor.

[0023] The linkage unit includes a U-shaped drive block 4 and a plunger rod 3. The U-shaped drive block 4 is connected to a rolling bearing 12, and a wear-resistant backing plate 11 is provided at the joint to reduce the friction between the U-shaped drive block and the rolling bearing. , to extend the service life, one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com