A screen printing method of automobile glass heating wire and its printing screen

A technology of automotive glass and screen printing, which is applied to screen printing machines, printing machines, printing machines, etc. It can solve the problems of adjusting the printing thickness of metal heating wires and welding heads, so as to save capital costs, save usage, and avoid automobiles. The effect of cracked glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

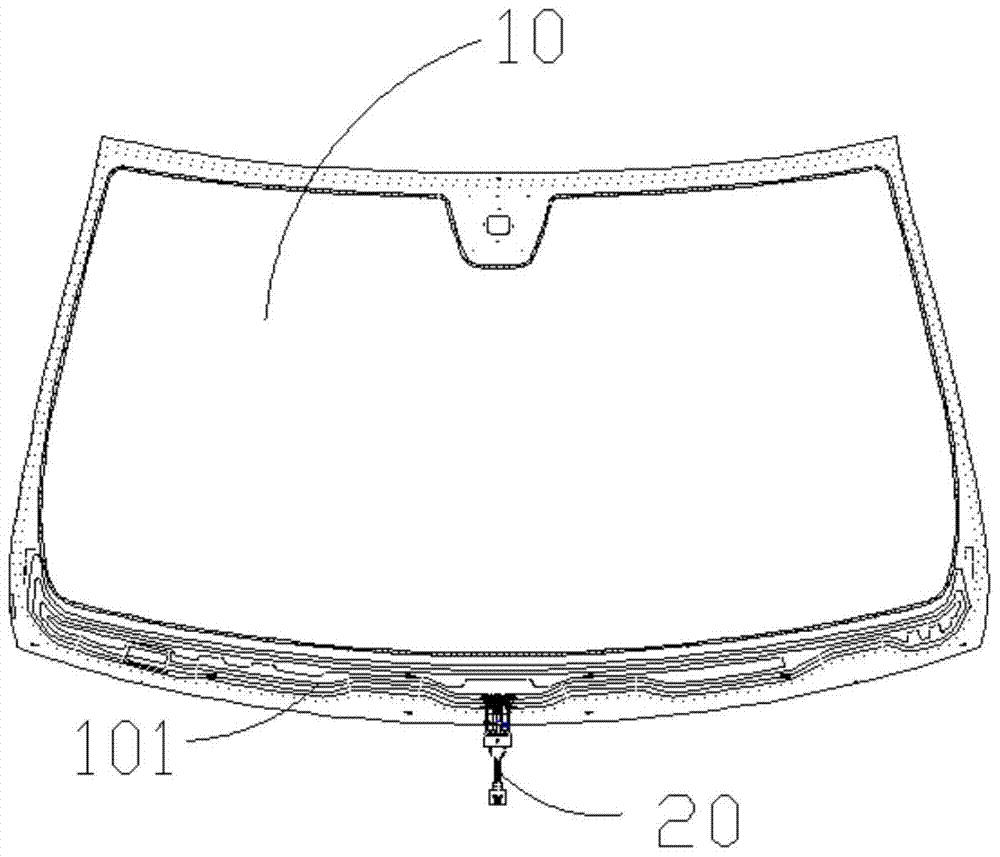

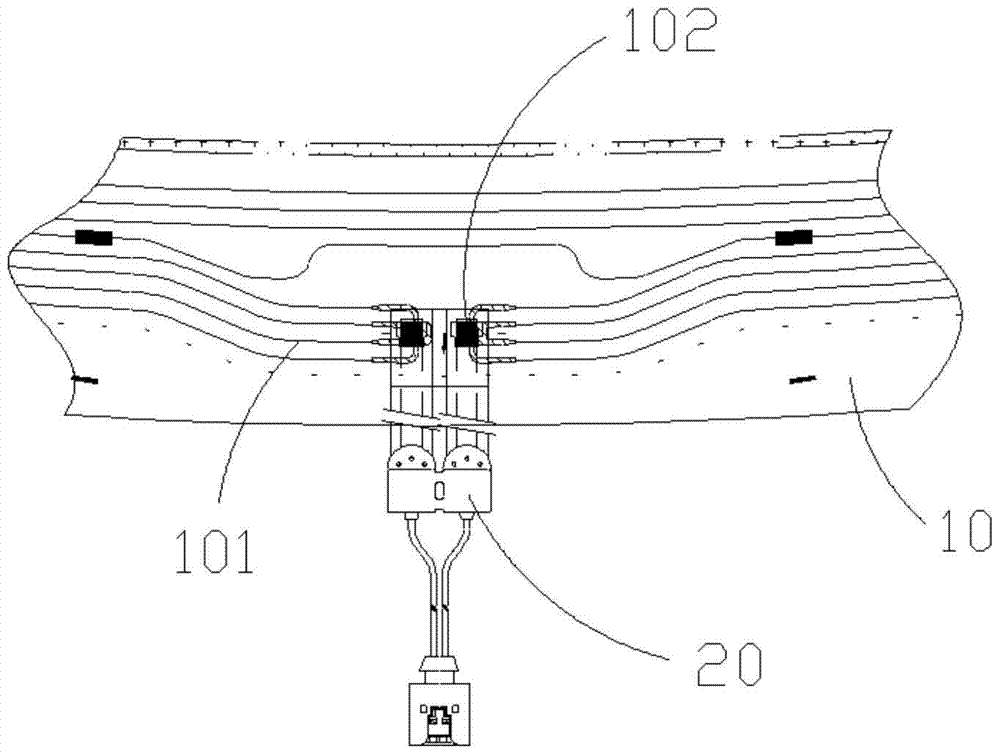

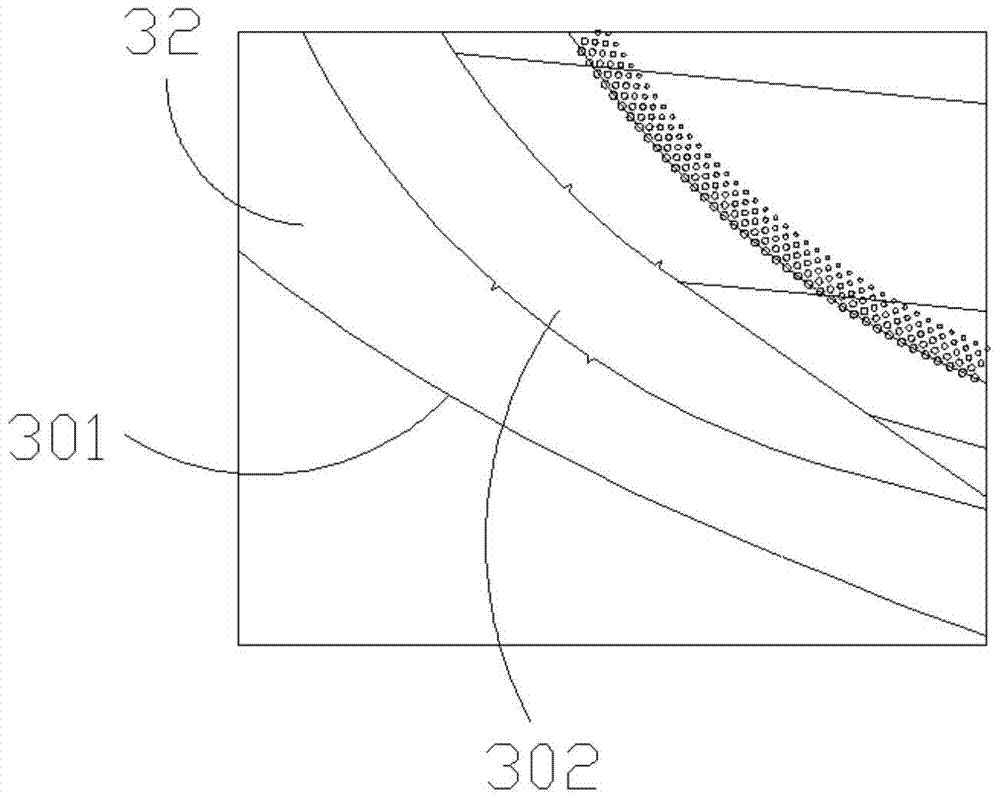

[0031] refer to figure 1 , figure 2 , the present invention is mainly aimed at the problem that the welding head 102 and the wire 20 that appear in batches because the metal printing layer of the welding head 102 is too thin during the production of automotive glass products with heating wires are poorly welded or even cannot be welded, and that they cannot be welded in one printing process. The problem of printing metal heating wires 101 with different thicknesses, so it is necessary to increase the printing thickness of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com