Method for cutting off heads and tails for squarer

A head-to-tail, open-machine technology, applied in the direction of fine work equipment, work accessories, stone processing equipment, etc., can solve the problems of inclination, inability to meet market demand, sawing skew, etc., to reduce production costs, improve product utilization, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

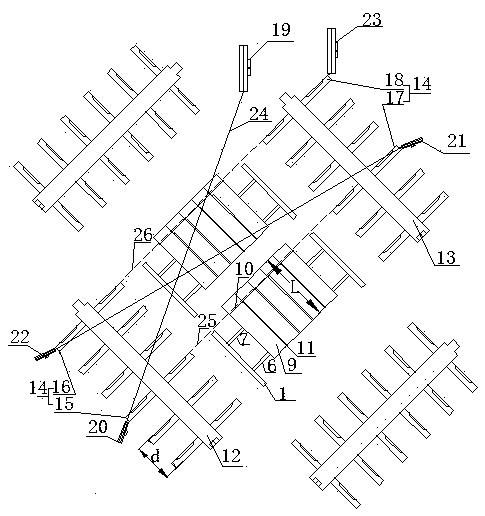

[0023] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] A method for opening the machine to cut off the head and tail, the method is:

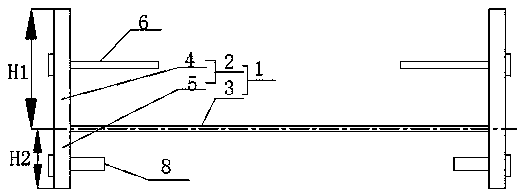

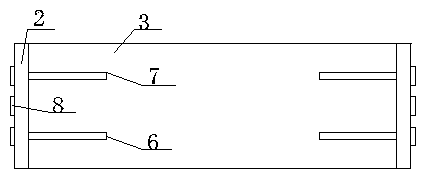

[0025] (1) Crystal brick clamping

[0026] A special jig 1 for crystal tiles is produced. The special jig for crystal tiles includes a side plate 2 and a bottom plate 3. There are two side plates 2 and the two ends of the bottom plate 3 are connected vertically to the two side plates 2 to form an integrated structure. The side plate 2 includes a crystal tile fixing plate 4 and a mounting connecting plate 5, the crystal tile fixing plate 4 and the mounting connecting plate 5 are respectively located on both sides of the bottom plate 3, and the height of the crystal tile fixing plate 4 is H1, so The height of the mounting connecting plate 5 is H2, the H1:H2=8:3, the crystal tile fixing plate 4 is provided with a first positioning bolt 6 and a second positioning bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com