Automatic height-detecting and reaming integrated machine

An automatic inspection and all-in-one machine technology, applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as increased production costs, inaccurate positioning, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

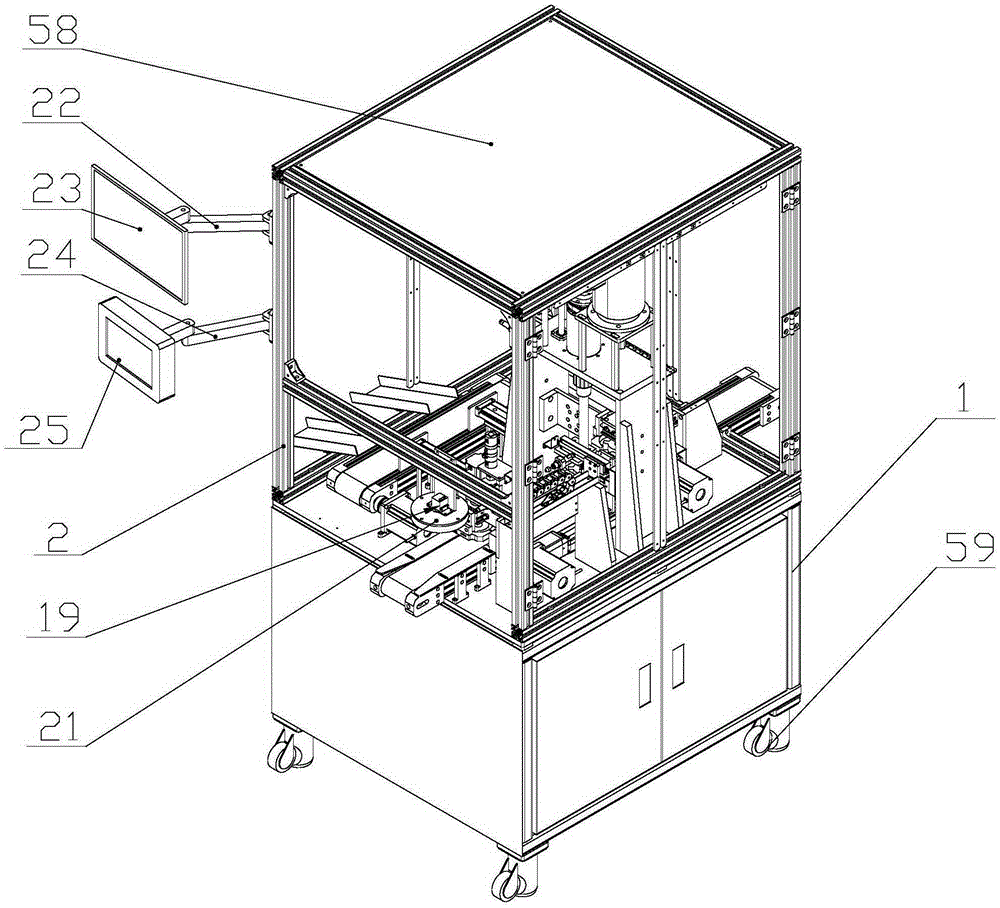

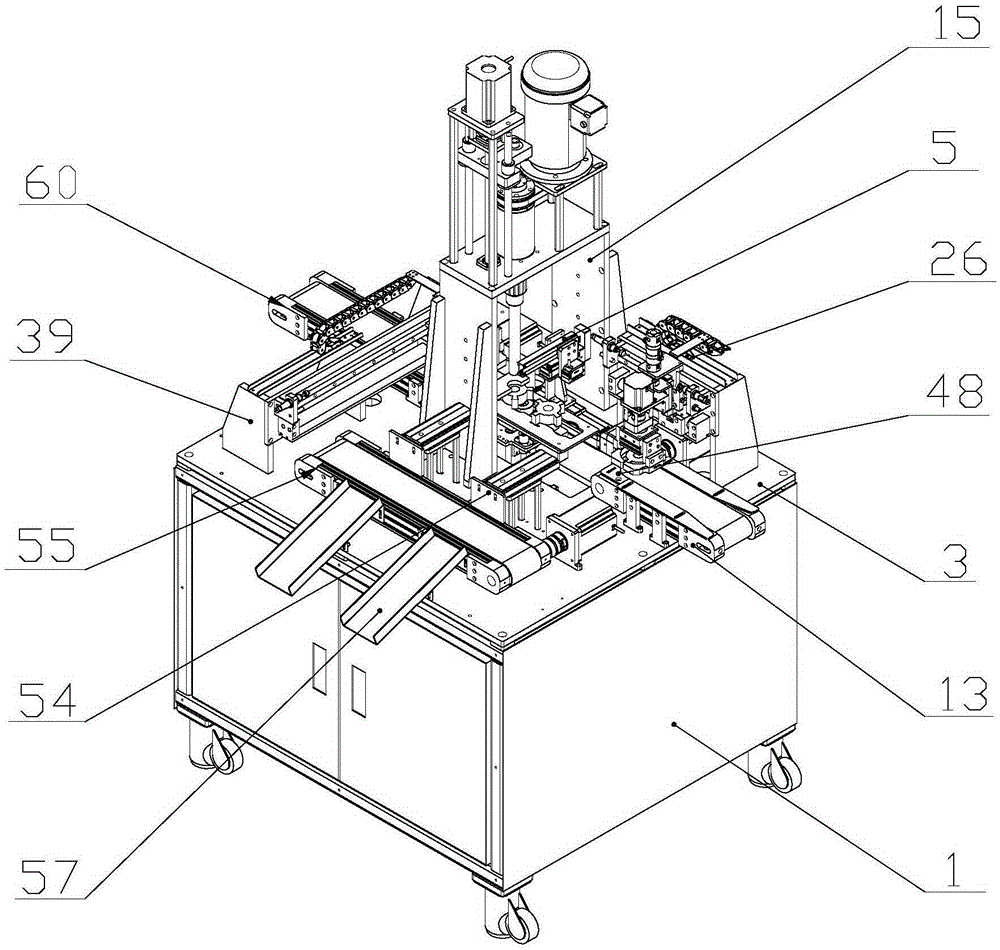

[0024] like Figure 1-9 The automatic height detection and reaming integrated machine shown is mainly composed of frame 1, pillar 2, bottom plate 3, feeding conveying mechanism 13, feeding mechanism, height measuring mechanism, transfer mechanism, reaming mechanism and unloading mechanism The bottom plate 3 is arranged on the upper end face of the frame 1, and the four corners of the frame 1 are provided with pillars 2, and the bottom plate 3 is successively provided with a feeding transmission mechanism 13, a feeding mechanism, a transfer mechanism, a height measuring mechanism, and a reaming hole Mechanism and the qualified product conveying mechanism 60, the described unloading mechanism is vertically arranged between the reaming mechanism and the qualified product conveying mechanism 60.

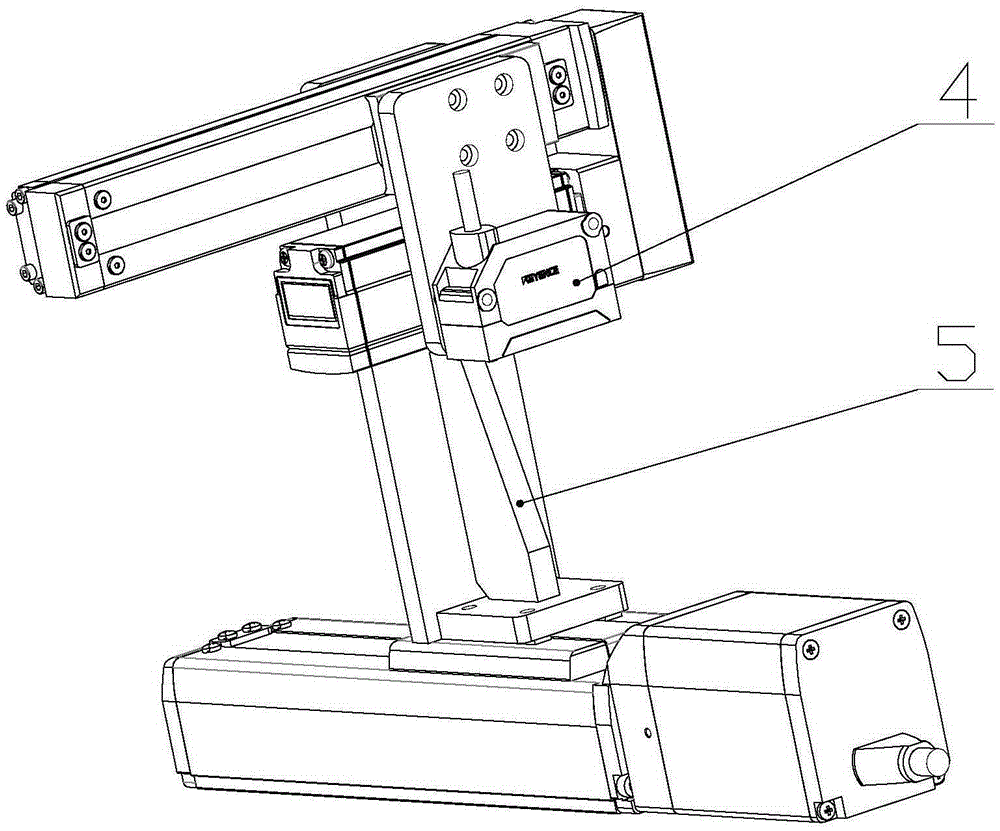

[0025] like image 3 The height-measuring mechanism shown is mainly composed of a laser sensor 4 and a height-measuring module group 5, the height-measuring module group 5 is movably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com