Dual-rotating direct connection device for automatic filter cleaning of bituminous coal firing substances

A kind of bituminous coal burning material, automatic filtration technology, applied in the direction of filtration separation, fixed filter element filter, chemical instrument and method, etc., can solve the problems of high labor intensity, reduce labor intensity, improve solution filtration efficiency and filtration quality , the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, the present invention will be further described in detail with reference to the drawings and specific embodiments.

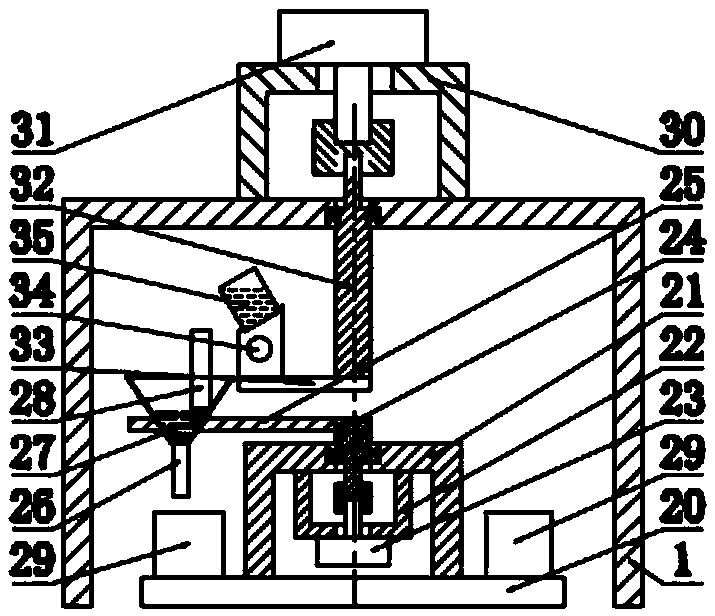

[0014] See figure 1 As shown, a dual-rotation direct connection device for automatic filtering and cleaning of bituminous coal burns of the present invention includes a funnel rotating device and a beaker rotating device; the funnel rotating device includes a bottom plate 20, a U-shaped rotating frame 21, a second motor frame 22, The second motor 23, the second rotating shaft 24, the rotating funnel frame 25, the funnel 26, the filter paper 27 and the waste liquid cup 29.

[0015] See figure 1 As shown, the bottom plate 20 is equipped with a U-shaped rotating frame 21 and N symmetrically distributed waste liquid cups 29; the second motor 23 is mounted on the second motor frame 22, and its output shaft is connected to the lower end of the second rotating shaft 24; The second rotating shaft 24 is mounted on the U-shaped rotating frame 21 through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com