Convenient assembly structure between boards

A convenient and board-to-board technology, applied in detachable cabinets, household appliances, applications, etc., can solve the problems of high price, time-consuming and labor-consuming, and residual formaldehyde in the room, and achieve the effect of overall beauty, low price and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

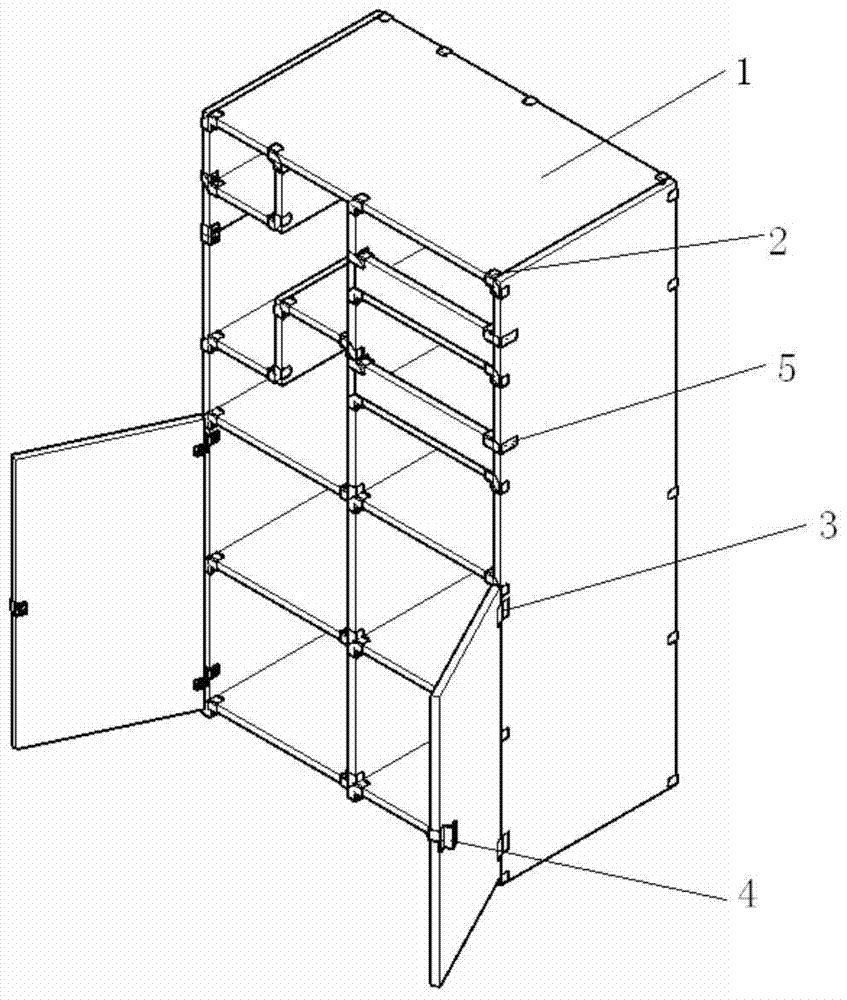

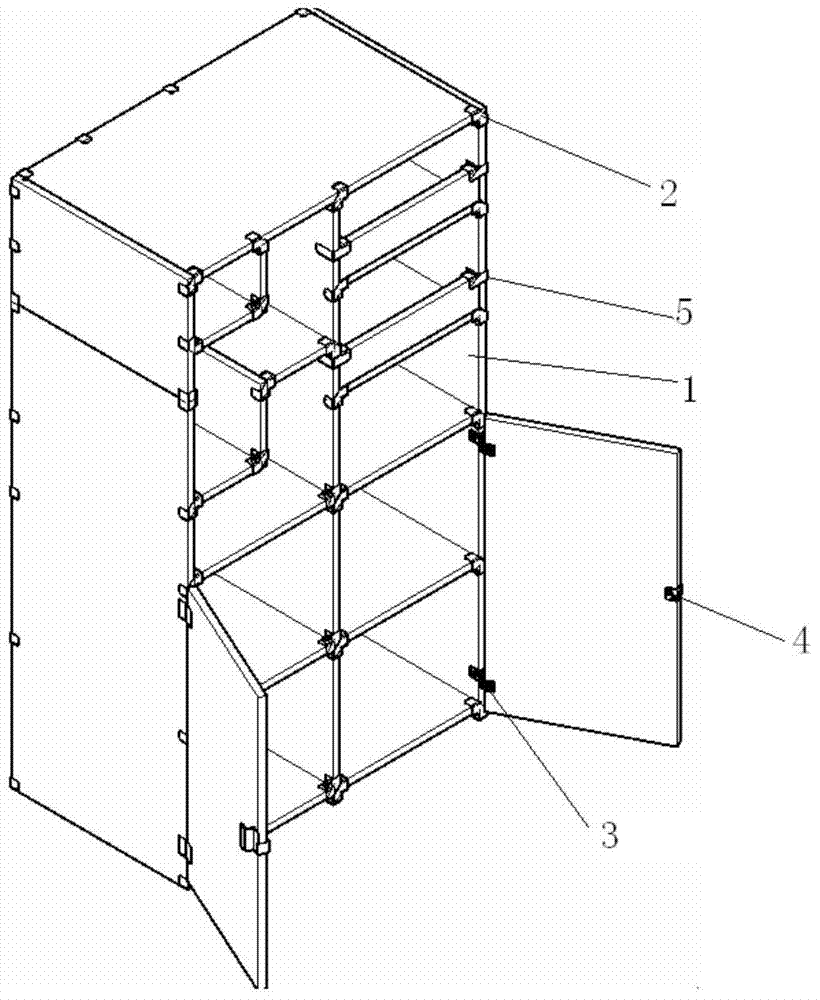

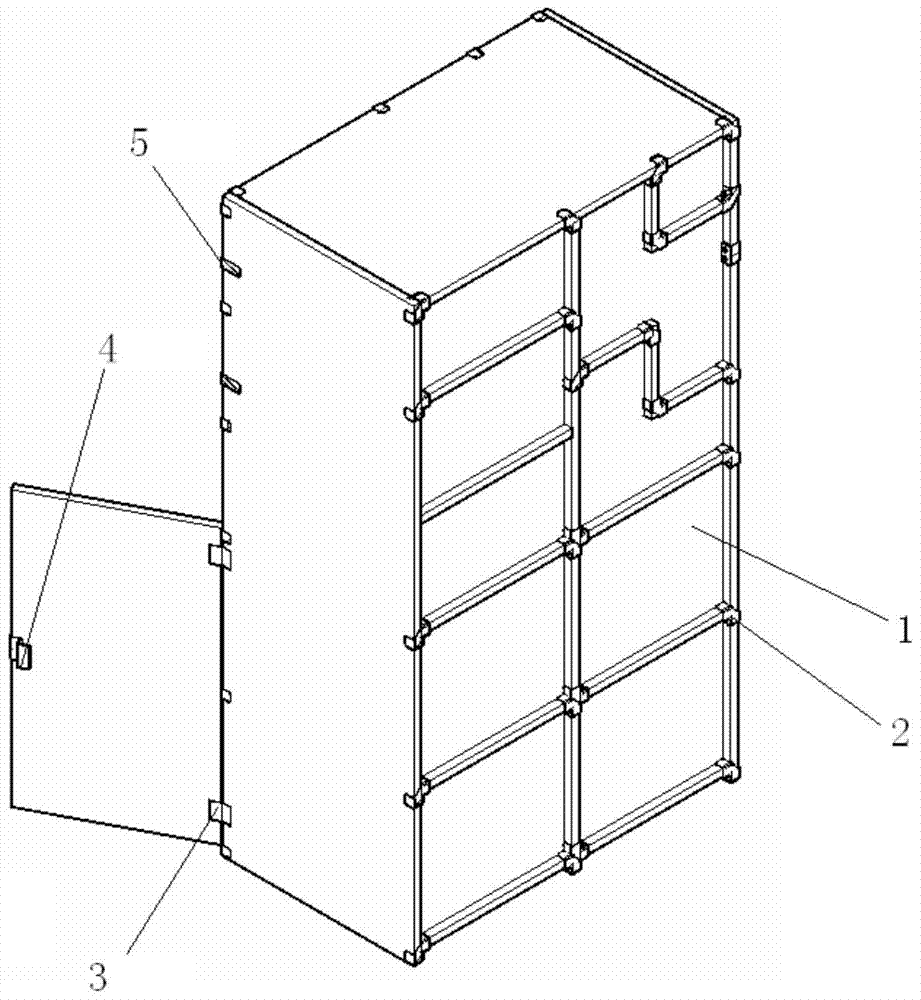

[0040] Embodiment: A convenient assembly structure between boards, including a board 1 and a corner connector 2, the corner connector 2 includes a fixed piece 21, a movable piece 22 and a corner adjustment piece 23, and the fixed piece 21 includes a bottom surface and a first , two side walls, the first and second side walls are respectively fixed on two opposite sides of the bottom surface, a channel for accommodating the plate 1 is formed between the first and second side walls, and the movable piece 22 is connected with the first side wall of the fixed piece 21 , the movable piece 22 is sandwiched between the first and second side walls of the fixed piece 21 , and the angle adjusting member 23 can adjust the distance between the movable piece 22 and the second side wall.

[0041] The boards 1 are assembled in pairs through the corner connector 2, and the two boards 1 are just inserted into the channel of the fixed piece 21 of the corner connector 2, and the movable piece 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com