Method for regenerating a filter element contaminated with solid materials in an exhaust gas system, and exhaust gas system

An exhaust equipment and filter technology, applied in mechanical equipment, exhaust devices, engine components, etc., can solve problems such as hindering exhaust gas recovery, increasing fuel consumption of internal combustion engines, and affecting emissions performance, and achieves accelerated regeneration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

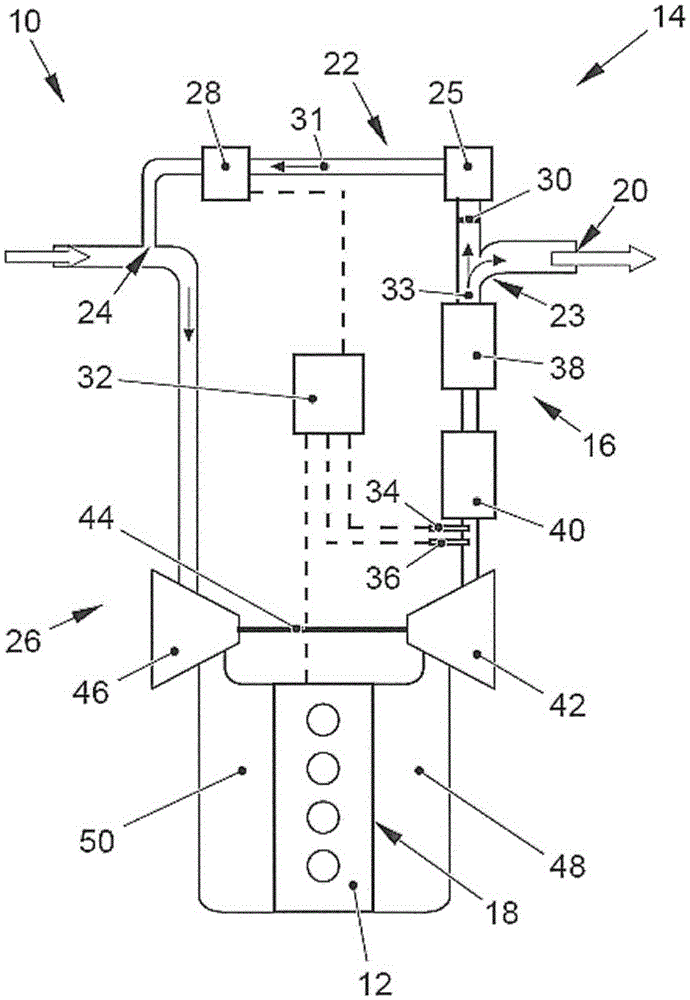

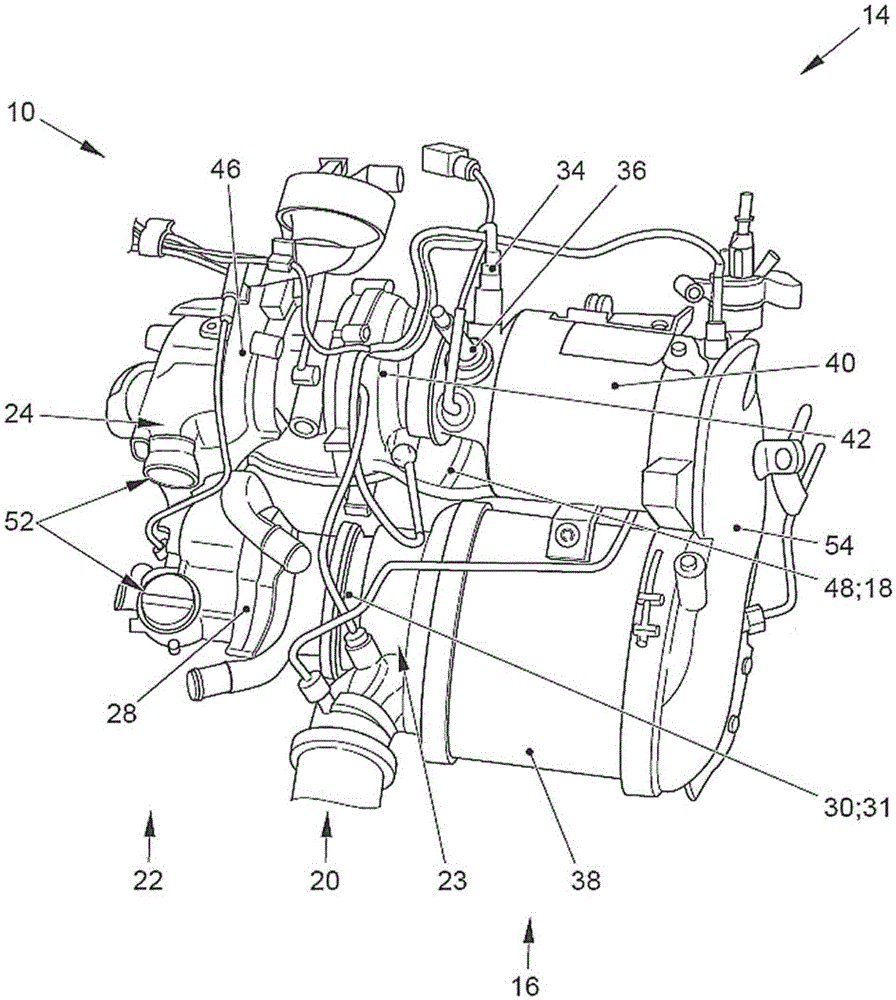

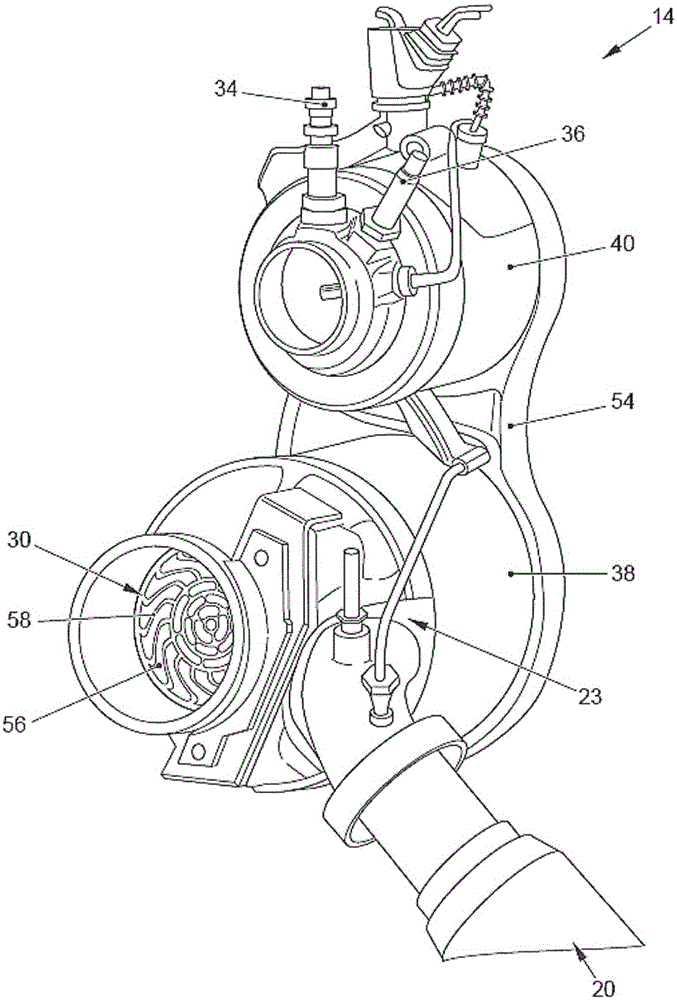

[0041] figure 1 A partial schematic view of the automobile 10 is shown. The automobile 10 includes an internal combustion engine 12 , such as a diesel engine, and an exhaust 14 . The exhaust device 14 has a main exhaust path 16 . The main exhaust path 16 is between an engine-side end 18 connected to the internal combustion engine 12 (by means of an exhaust elbow 48 of the exhaust device 14 ) and an outlet-side end 20 for discharging the exhaust gas of the internal combustion engine 12 into the environment extend. The exhaust apparatus 14 also has an AGR path 22 (AGR stands for Exhaust Gas Recovery) extending between the branch 23 of the main exhaust path 16 and the inlet-side end 24 . The inlet-side end 24 is connected to an air supply 26 of the internal combustion engine 12 . The exhaust apparatus 14 also includes an AGR valve 28 in the AGR path 22 .

[0042] Furthermore, the exhaust system 14 also includes a filter element 30 between the engine-side end 18 and the AGR v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com