Oxide chemical vapor deposition apparatus and oxide chemical vapor deposition method

A technology of chemical vapor deposition and oxide, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of shortened life, damage, furnace wire failure, etc., to improve quality and uniformity, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

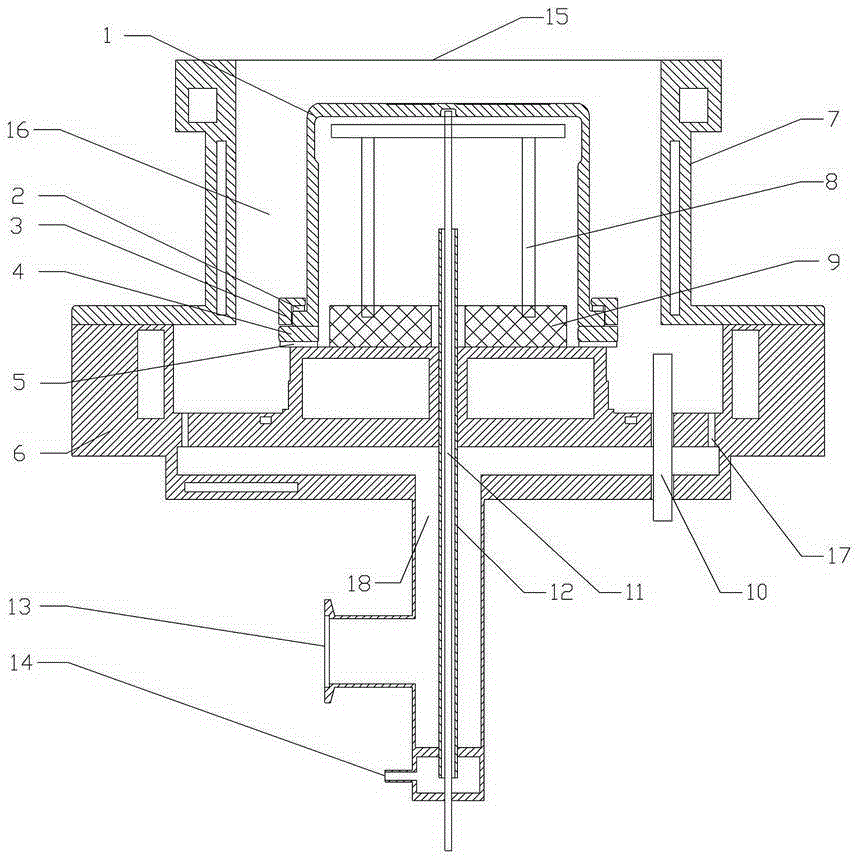

[0018] Embodiments of the present invention are further described below in conjunction with the accompanying drawings, figure 1 is a schematic illustration of the operation of an embodiment device according to the present invention. It should be understood that the disclosed figure 1 The components of the device according to the embodiment of the present invention are highlighted, that is to say, figure 1 It is not intended to illustrate every individual component of the apparatus of the invention.

[0019] Such as figure 1 As shown, an oxide chemical vapor deposition device mainly includes: slide tube 1, gasket 2, compression ring 3, base 6, cavity outer wall 7, heater 8, central gas tube 12, heater mounting seat 9. Reaction gas inlet 15, reaction chamber flow channel 16, bottom flow channel 18, central air inlet 14, exhaust gas port 13, exhaust gas rectification hole 17, characterized in that the compression ring 3 presses the slide tube 1 through the gasket 2 Tightly fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com