Large-scale biological negative electrode microbial fuel cell stack apparatus

A fuel cell stack and bio-cathode technology, which is applied in the field of water treatment, can solve the problem of no bio-cathode microbial fuel cell for wastewater treatment, and achieve the effects of improving long-term stability, large processing capacity and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0013] Embodiment 1: Device installation

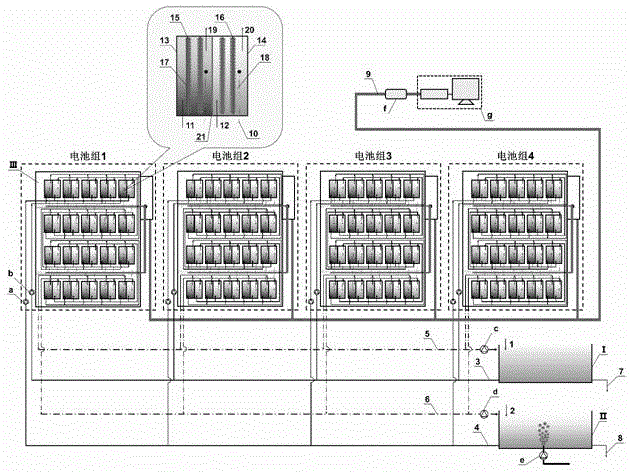

[0014] device according to figure 1 The schematic diagram shown is installed: the anion exchange membrane 21 divides the microbial fuel cells in the battery pack 1 and the battery pack 2 into an anode chamber 13 and a cathode chamber 14, and the cation exchange membrane 21 divides the microbial fuel cells in the battery pack 3 and the battery pack 4 The fuel cell is divided into an anode chamber 13 and a cathode chamber 14, wherein the anion exchange membrane 21 and the cation exchange membrane 21 adopt a non-toxic ion exchange membrane with a transmittance of 94%, a thickness of 0.3 mm, and a burst strength ≥ 0.5 MPa; A carbon felt with a thickness of 5-6 mm is loaded into the chamber 13 as the anode 15, and a carbon felt with a thickness of 5-6 mm is loaded into the cathode chamber 14 as the cathode 16. The anode 15 distributes anaerobic microorganisms 17 with a thickness of 50-70 μm, and the cathode 16 The aerobic microorganisms 1...

Embodiment approach 2

[0015] Embodiment 2: device operation

[0016] After the installation of the device is completed, in the anode pool I, biochemically treatable organic wastewater is added from the anode pool inlet 1 to make it in an anaerobic state with a dissolved oxygen concentration lower than 0.2mg / L, and through the anolyte inflow pipe 3 and the anode circulation When the pump a is lifted, it is injected into the anode chamber 13 from the water inlet 11 of the anode chamber. The organic matter in the wastewater is initially degraded under the action of anaerobic microorganisms 17. At the same time, the electrons generated by the degradation of pollutants are transferred to the anode 15. Discharged from the anode chamber water outlet 19, merged with the same level of microbial fuel cell anode chamber 13 and used as the next level and as the water intake of the next stage microbial fuel cell anode chamber 13, flows into the anode outflow pipe 5 after four stages of degradation, and passes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| bursting strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com