A laser light guide plate structure

A technology of light guide plate and laser, applied in the field of light guide plate, can solve the problems of inability to satisfy consumers, single brightness and color tone, etc., and achieve the effect of rich color tone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] Examples: The following specific examples illustrate the implementation of the present invention, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

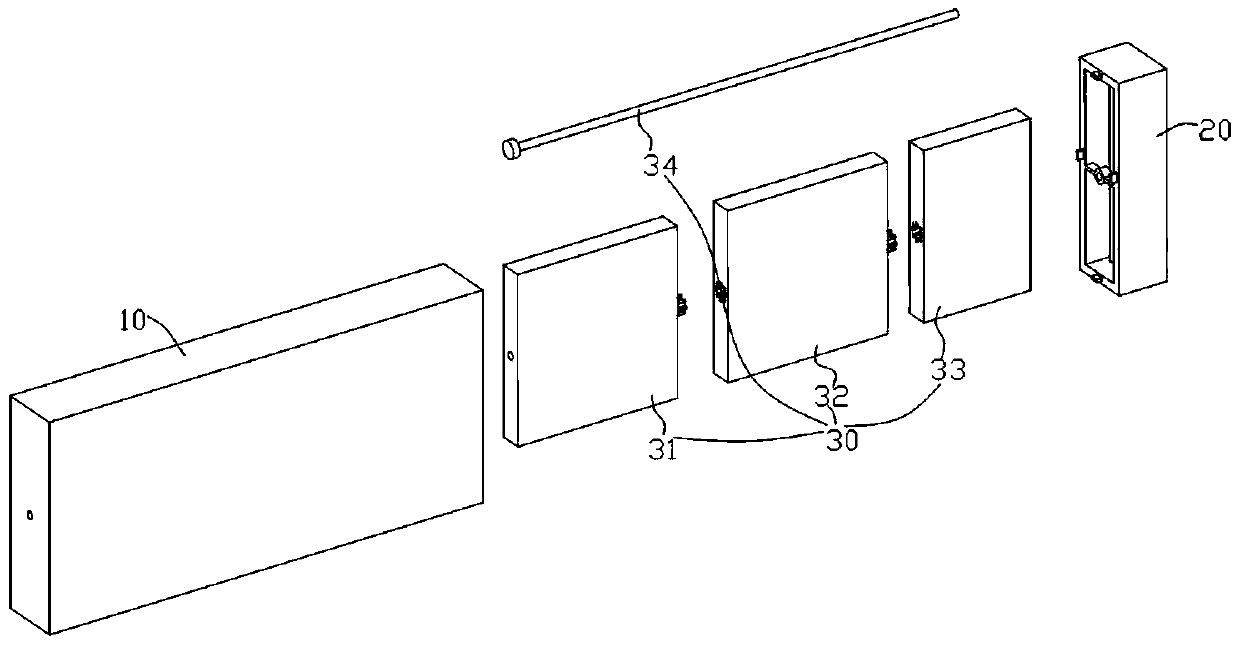

[0028] See figure 1 and figure 2 As shown, a laser light guide plate structure includes: a first housing 10 with an open end; the opening end installed on the first housing 10 and the first housing 10 are jointly surrounded to form a closed chamber The second housing 20; the light guide partition unit 30 installed in the first housing 10; and the light source 40 installed in the second housing 20. See figure 2 As shown, the light guide baffle unit 30 includes a bolt 34 penetrating through the side wall of the first housing 10 and a first light guide baffle 31 and a second light guide baffle that are sequentially sleeved on the bolt 34 . Plate 32 and the third light guide partition 33; see Figure 5 to Figure 7 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com