A Specimen Fixture with Self-Adaptive Contact of Frictional Surface

A friction surface, self-adaptive technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problem of friction pairs not being in good contact, and achieve the effect of uniform force and avoiding cumbersome processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

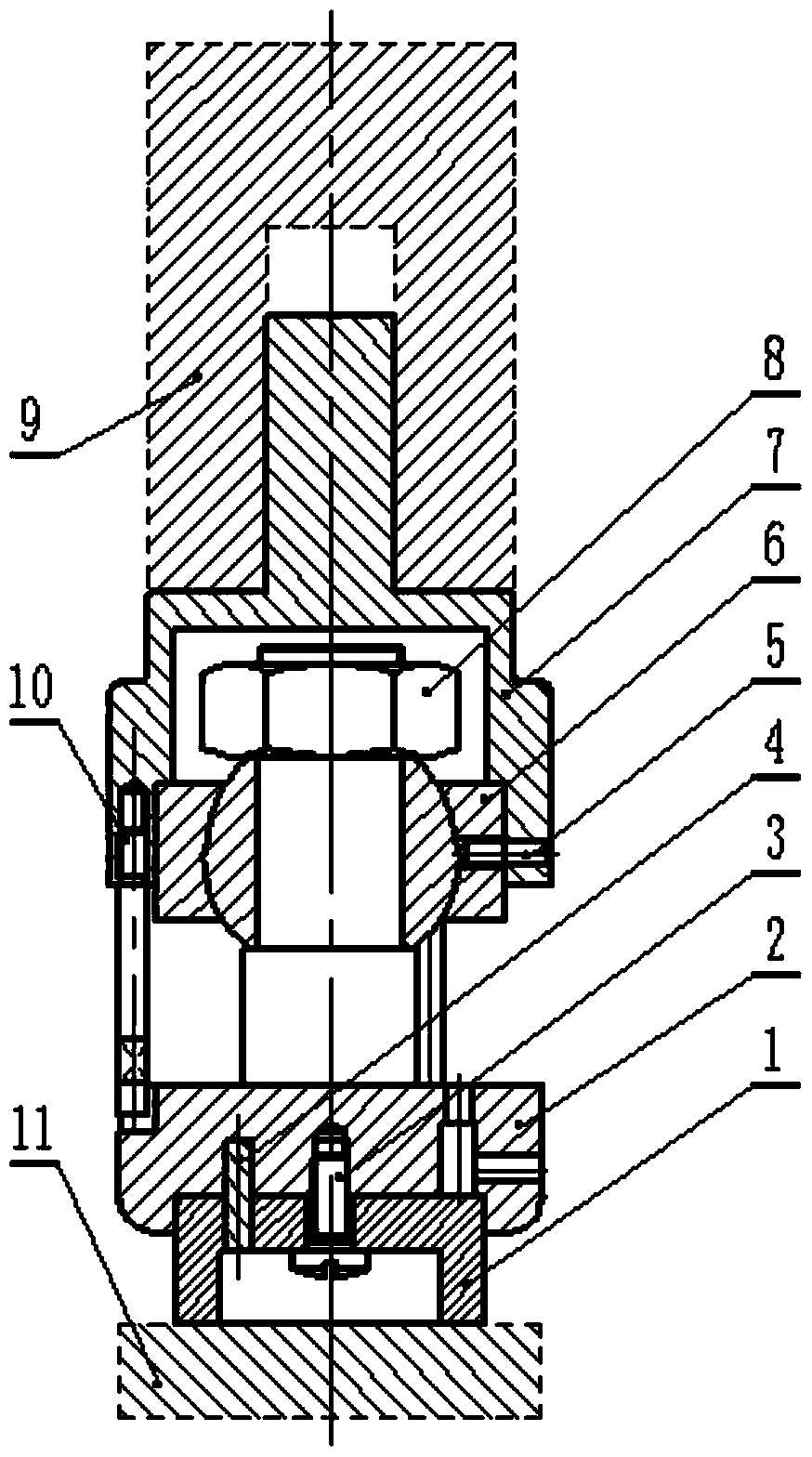

[0026] Embodiment 1, as shown in Fig. 1 (a), the specimen fixture of frictional surface self-adaptive contact is mainly composed of ring specimen 1, clamping piece 2, slotted spherical cylindrical head screw 3, positioning pin 4, slotted cone end Set screws 5, centripetal joint bearings 6, cup-type fixing parts 7, hexagonal nuts 8, and studs 10; On the ball bearing 6, the outer wall of the cup-type fixing part 7 is provided with an upper slotted taper end set screw 5 fixed together with the radial joint ball bearing 6, and the end surface of the cup-type fixing part 7 is provided with abutment The stud 10 on the opposite end surface of the clamping part 2;

[0027] The clamping part 2 is T-shaped, the T-shaped head is a disk, the T-shaped rear part is a stepped shaft that is fitted with a radial joint ball bearing 6, and the tail of the stepped shaft is threaded to fix the radial joint ball bearing 6 8 hexagonal nuts, the shaftless end of the clamping piece 2 has an inner gro...

Embodiment 2

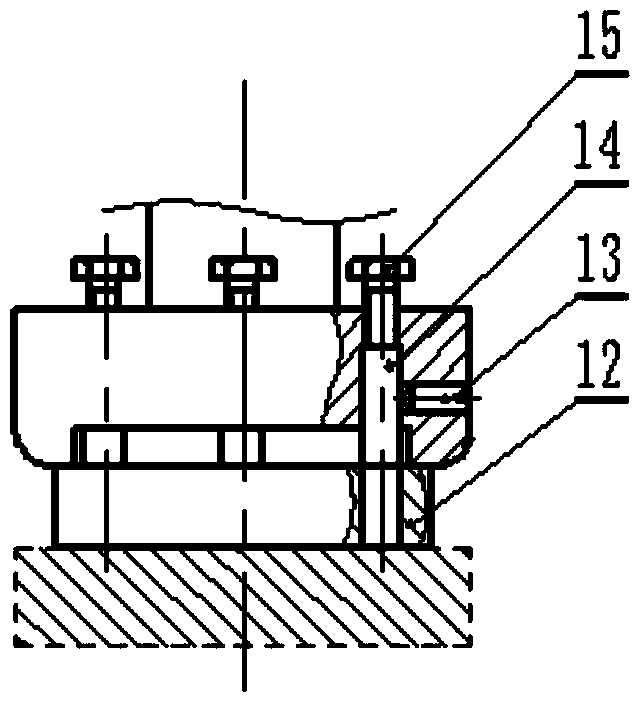

[0031] Embodiment 2 is basically the same as Embodiment 1, and the similarities are omitted. The difference is as shown in Figure 1(b), a spacer 12 is provided under the inner groove at the shaftless end of the head disc of the clamping part 2, and a pad 12 is provided on the spacer 12 to match the circular shape of the head of the clamping part 2. The three through holes corresponding to the three bolt holes on the plate are provided with a pin test piece 14 that enters the pad 12 from the bolt hole, and the top of the pin test piece 14 is provided with a fixing bolt 15, and the pin test piece 14 A set screw 13 with a lower slotted taper end passing through the side wall of the head disc of the clamping part 2 is provided on the side. According to the needs of the experiment, the test piece under the pad 12 can be a plate test piece or a pin test piece, and the contact of the pin test piece 14 with the plate test piece or the pin test piece can realize the pin-disc experiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com