Real-time calculation method of abrasion loss of disc cutter of hard rock tunnelling boring machine

A technology of tunnel boring machine and real-time calculation, applied in the direction of measuring devices and instruments, can solve problems such as the safety and efficiency of tunnel construction, poor working conditions of disc hob, and complicated rock breaking process, so as to achieve clear design ideas and improve Driving efficiency, logical and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

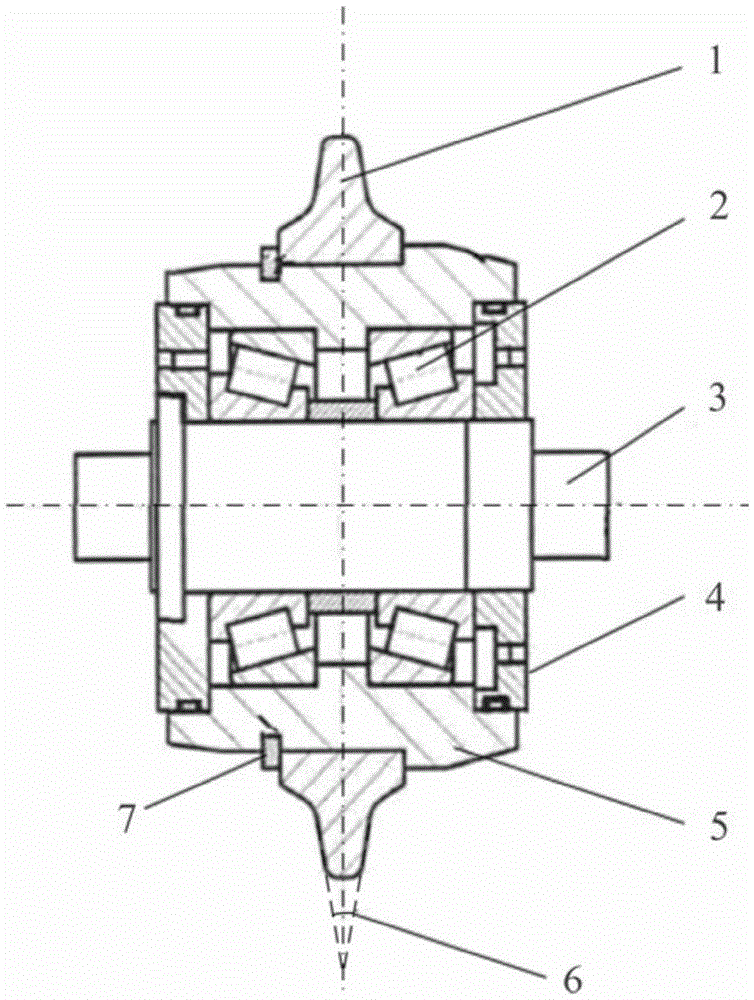

[0044] In the tunnel engineering of this embodiment, the structural parameters of the hard rock TBM used are as follows: 38 disc-shaped hobs with a constant section of 432 mm are installed on the cutter head, that is, the initial radius R of the hob is 216 mm, and 0°<the edge of the hob cutter ring Angle 6≤5°, the sum of all hob installation radii is 62.415m. The project is constructed under hard rock conditions. The specific steps of the method for realizing the real-time calculation of hob wear during hard rock TBM excavation are as follows:

[0045] The first step is to calculate the equivalent hob cutting coefficient and depth of cut of the TBM cutter head in real time:

[0046] Firstly, the tunneling parameters collected in real time by hard rock TBM construction equipment are used, including cutterhead thrust, cutterhead torque, cutterhead speed and tunneling speed, and then the structural parameters of TBM cutterhead tools are used, including the number of cutters on th...

Embodiment 2

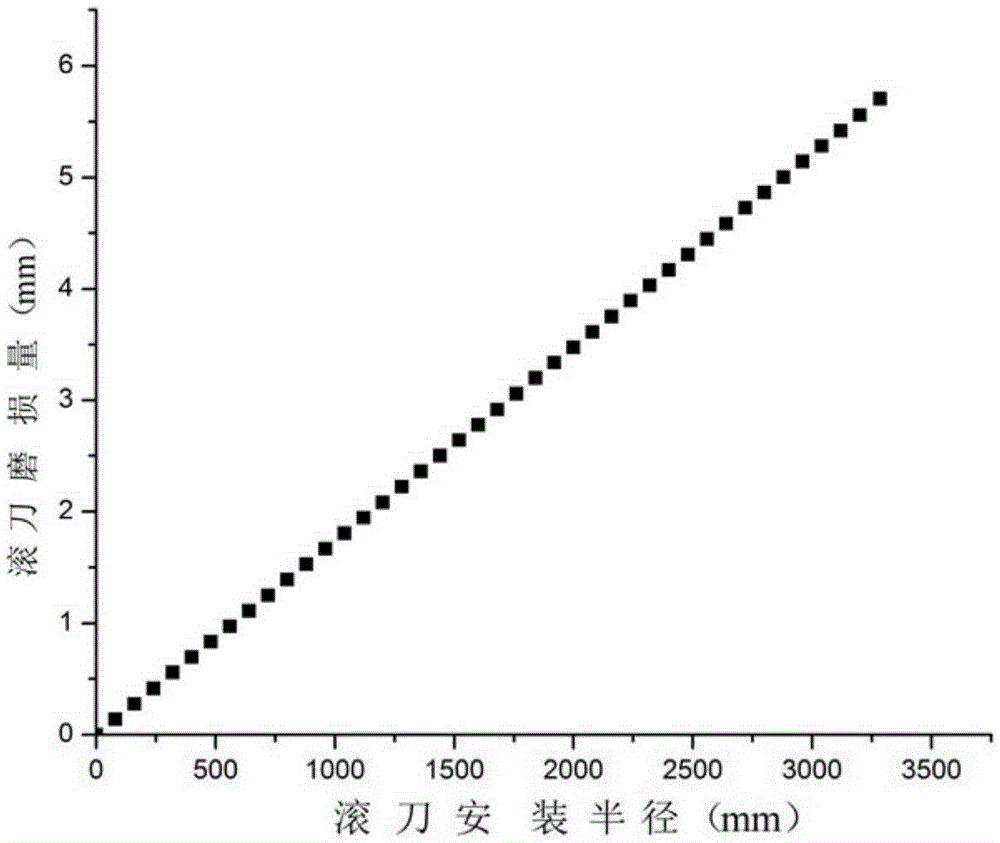

[0084] In the tunnel engineering of this embodiment, the structural parameters of the hard rock TBM used are as follows: 71 disc-shaped hobs of 432 mm are installed on the cutter head, that is, the initial radius R of the hob is 216 mm, and the edge angle 6 of the hob cutter ring is 20° , the sum of the installation radii of all hobs is 172.62m, and the installation radii of the cutters on each cutter position are as follows Figure 4 Shown: the cutterhead axis of the hard rock TBM cutterhead used in the tunnel engineering in this embodiment is located at the center of the cutterhead, the diameter of the cutterhead is 8800mm, and 71 432mm disc-shaped hobs are installed, and the cutter position numbers are 1, 2, 3. ..., 69, 70, 71, the larger the tool position number, the farther the tool is from the center of the cutter head; the installation radius of No. 1 tool on the cutter head is 42mm; among No. 1 to No. The installation radius difference between them is 84mm; the total i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com