Multi-layer and multi-stage pipe tunnel slide type veneer drying device

A drying device and pipe hole technology, which is applied in the direction of drying gas arrangement, heating device, drying chamber/container, etc., can solve the problems of inability to reduce equipment manufacturing cost, high equipment manufacturing cost and use cost, and more heat dissipation, and achieve favorable The effects of popularization and use, low cost of manufacturing equipment, and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

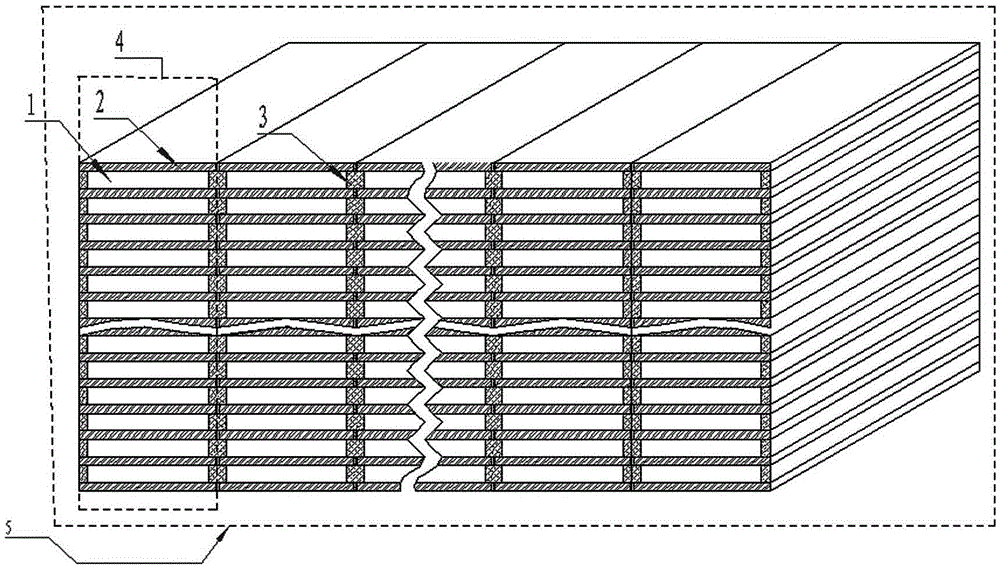

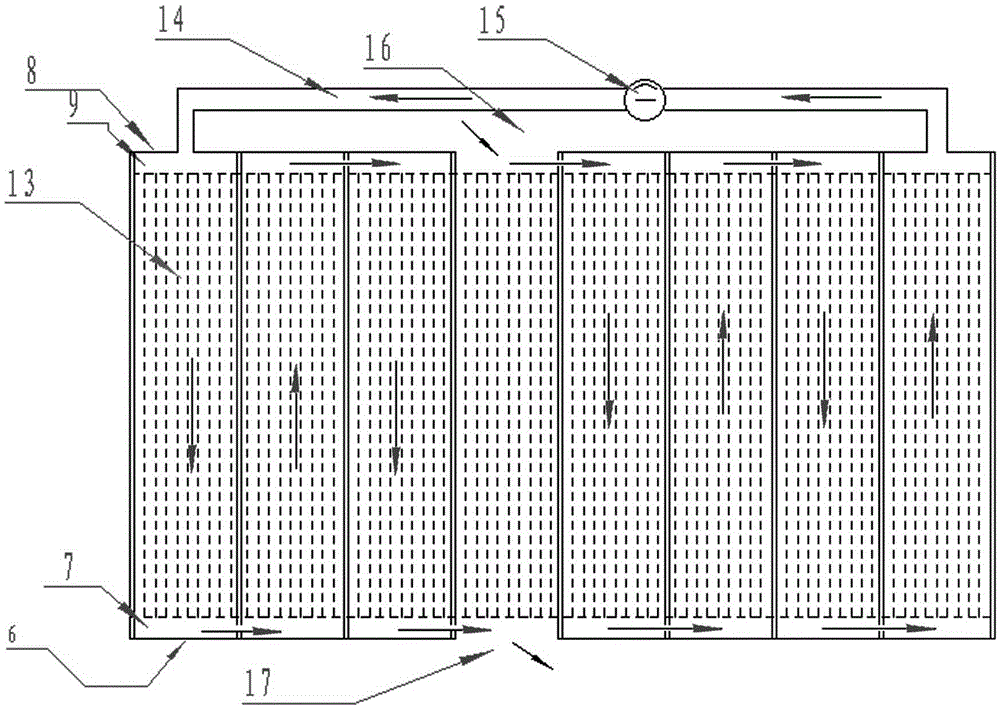

[0027] refer to Figure 1-4 , a 30-layer eight-stage pipe hole slide type veneer drying device, including a drying box (not shown in the figure), a heat-conducting oil boiler 18, a heat-conducting oil circulation pipeline 23 connecting the drying box and the heat-conducting oil boiler 18, and set in The circulating oil pump 20 on the pipeline is provided with a drying rack 5 in the drying box, and a heat insulation layer is also provided on the periphery of the drying box; the drying rack 5 is composed of two hundred and forty Eight heating plates 2 with embedded heating oil pipelines and two hundred and seventy load-bearing support partitions 3 arranged vertically and parallel to each other are constructed. There are 240 flat rectangular tube-shaped spaces in 30 floors and eight rows. This tube-shaped space is called the tube-hole drying room 1; the upper and lower surfaces of each tube-hole drying room 1 are respectively heating plates. 2, the left and right sides are respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com