Movable valve seat type spring loaded type relief valve

A direct-acting, moving valve seat technology, applied in the direction of functional valves, lifting valves, safety valves, etc., can solve the problems of incomplete compensation, cavitation wear, small pressure adjustment range, etc., and achieve pressure stability increase, Reduce impact force and erosion, avoid the effect of seat polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

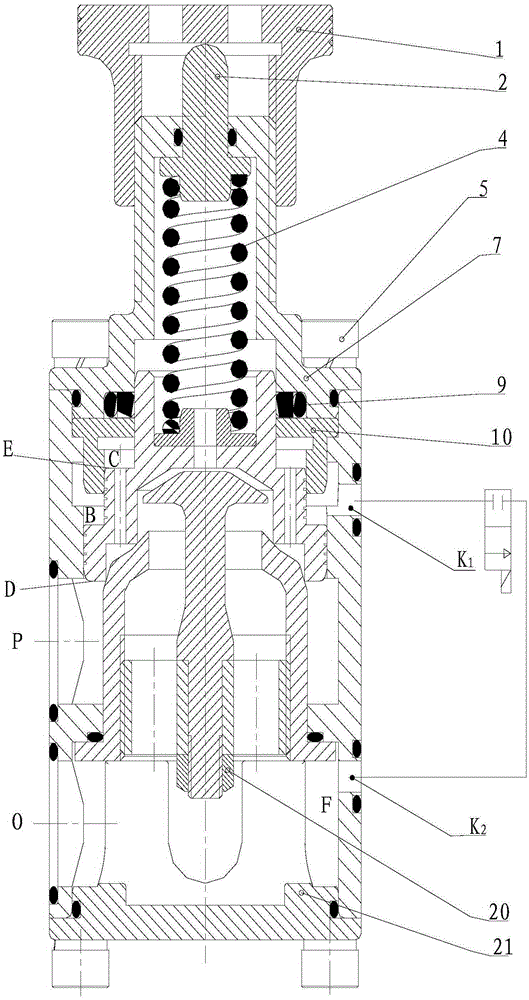

[0030] Example 1, such as figure 1 As shown, this embodiment discloses a movable valve seat type direct-acting overflow valve, which includes a valve body 13 with a cavity, and a water inlet P and a water outlet O on the valve body communicate with the above-mentioned cavity; the valve The valve core 14 and the valve seat 12 are arranged in the cavity of the body 13, the valve core 14 is fixed in the cavity in the valve body through the rear end cover 21, and the valve seat 12 is embedded in the cavity inside the sleeve 10 and the valve body 13, The sleeve 10 is pressed together with the front end cover 7; a spring 4 is arranged in the inner cavity of the front end cover 7, a spring ejector 2 is installed on the top of the spring 4, and a spring seat 11 is provided on the bottom of the spring 4, and one end of the spring 4 is in contact with the spring ejector 2 , the other end abuts against the spring seat 11, the spring seat 11 is installed in the axial through hole on the u...

Embodiment 2

[0037] Example 2, such as figure 2 As shown, in this embodiment, on the basis of Embodiment 1, a control hole K1 is opened on the valve body to communicate with the space B between the first step of the valve seat and the sleeve; and the space F between the valve core and the rear end cover The connected control hole K2; the control holes K1 and K2 are respectively connected to the two ports of the two-position two-way electromagnetic reversing valve.

[0038] In this embodiment, if the two-position two-way electromagnetic reversing valve is opened, the fluid in space B can flow into space F through control holes K1 and K2, and space C loses pressure due to no fluid. With the pre-tightening force on the valve seat, the valve seat can move to the top, the overflow valve opens, and the fluid flows out of the overflow valve through the valve core and the water outlet. Due to the low spring stiffness, the fluid pressure only needs to overcome a small spring force to fully open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com