Mounting assembly of thermostat for gasoline engine

A technology for installing components and thermostats, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., and can solve problems such as the influence of thermostat and thermostat seat sealing, affecting the sealing performance of cooling water, and temperature sensor distortion , to achieve the effect of simple structure, accurate installation direction and guaranteed sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

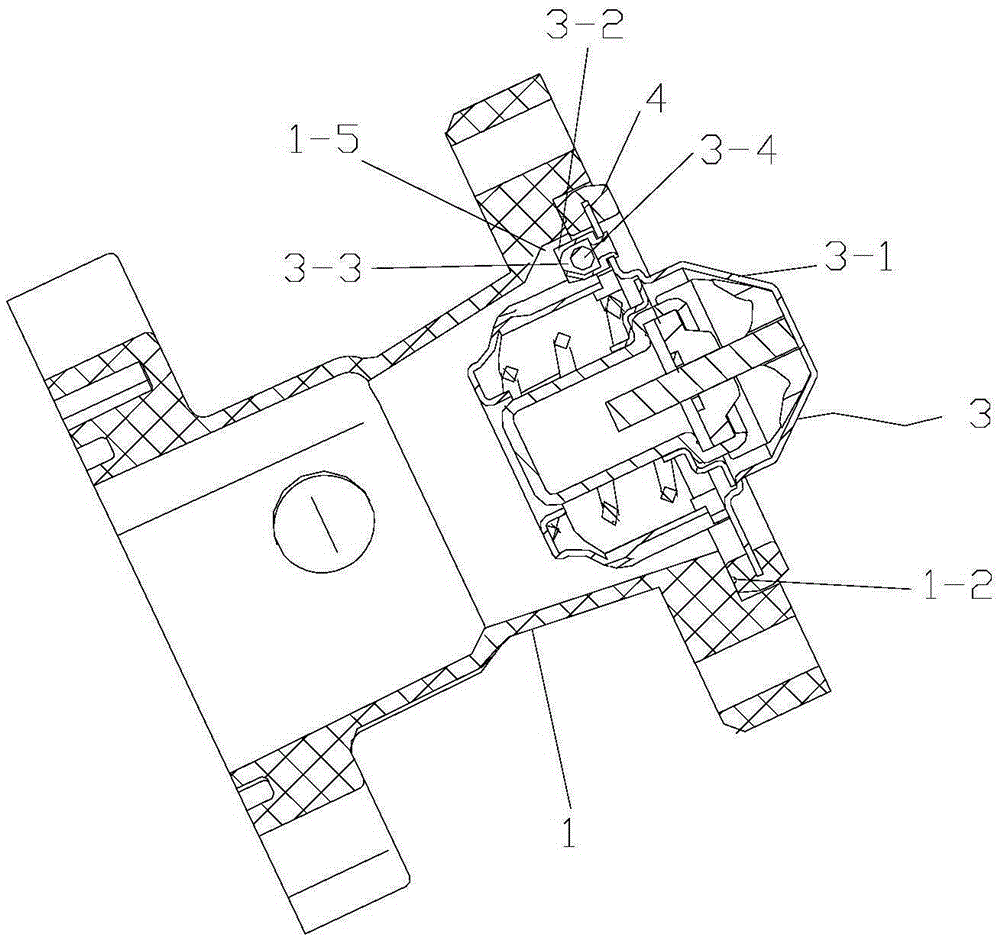

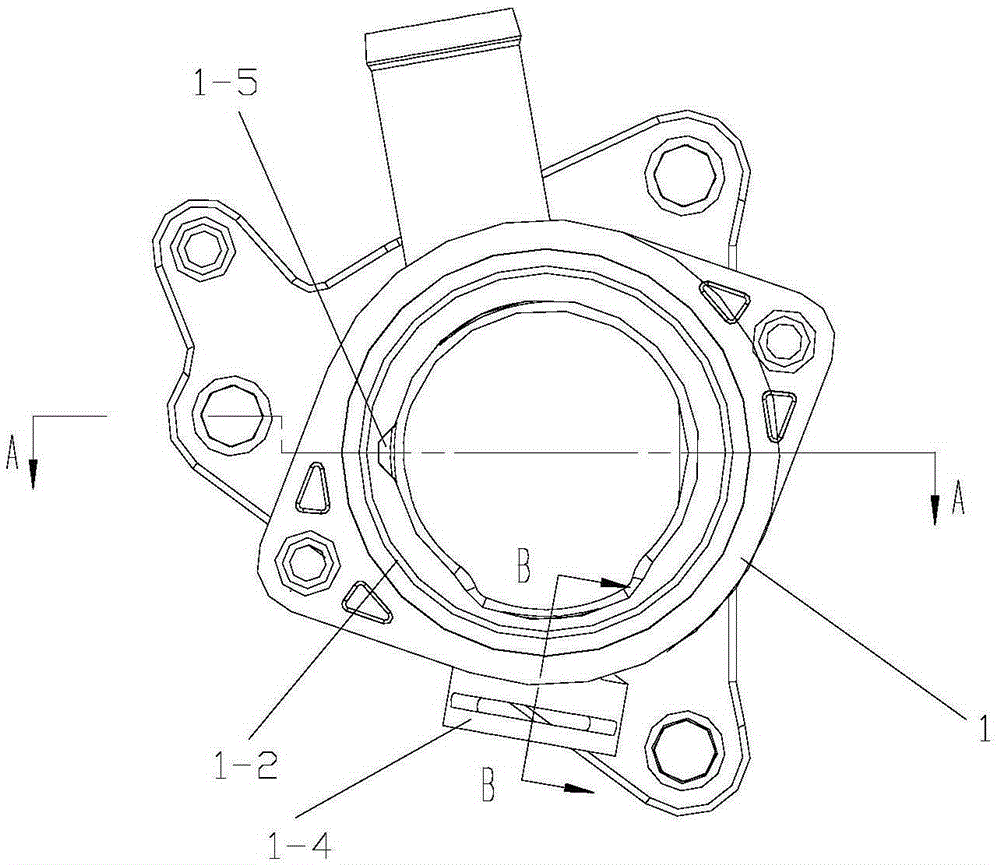

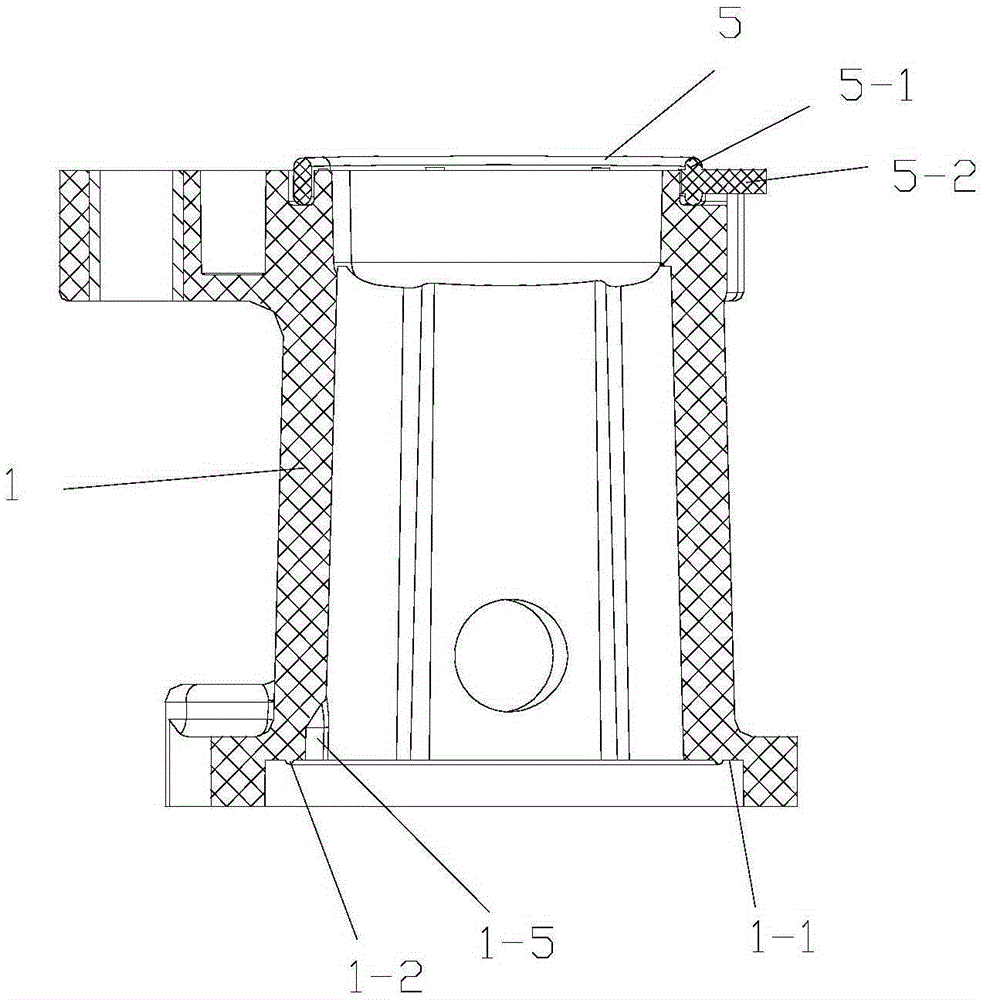

[0023] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 It is a structural schematic diagram of the thermostat seat in the present invention, image 3 for figure 2 A-A direction view, Figure 4 for figure 2 B-B direction view, Figure 5 for figure 2 side view, Figure 6 for figure 2 Rear view, Figure 7 It is a structural schematic diagram of a thermostat in the present invention, Figure 8 It is a schematic diagram of the assembly of the overall structure of the present invention combined with the end cover of the thermostat, as shown in the figure: the engine thermostat of this embodiment includes a thermostat 3 and a thermostat seat 1, and the upper end of the thermostat seat 1 is formed for installation The valve seat 1-1 of the thermostat 3, the inner wall of the thermostat seat 3 close to the valve seat 1-1 is provided with a limit groove 1-5 for limiting the installation of the thermostat 3, and the thermostat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com