An aluminum alloy formwork protruding section profile and its unit formwork structure

An aluminum alloy formwork and aluminum alloy technology, which is applied in the fields of formwork/formwork components, building structures, and on-site preparation of building components, can solve the problems of unguaranteed safety performance, unreasonable cross-sectional structure, and difficulties in making and forming, etc. problems, to achieve the effect of simple molding, quick and easy disassembly and assembly, and provide space for ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

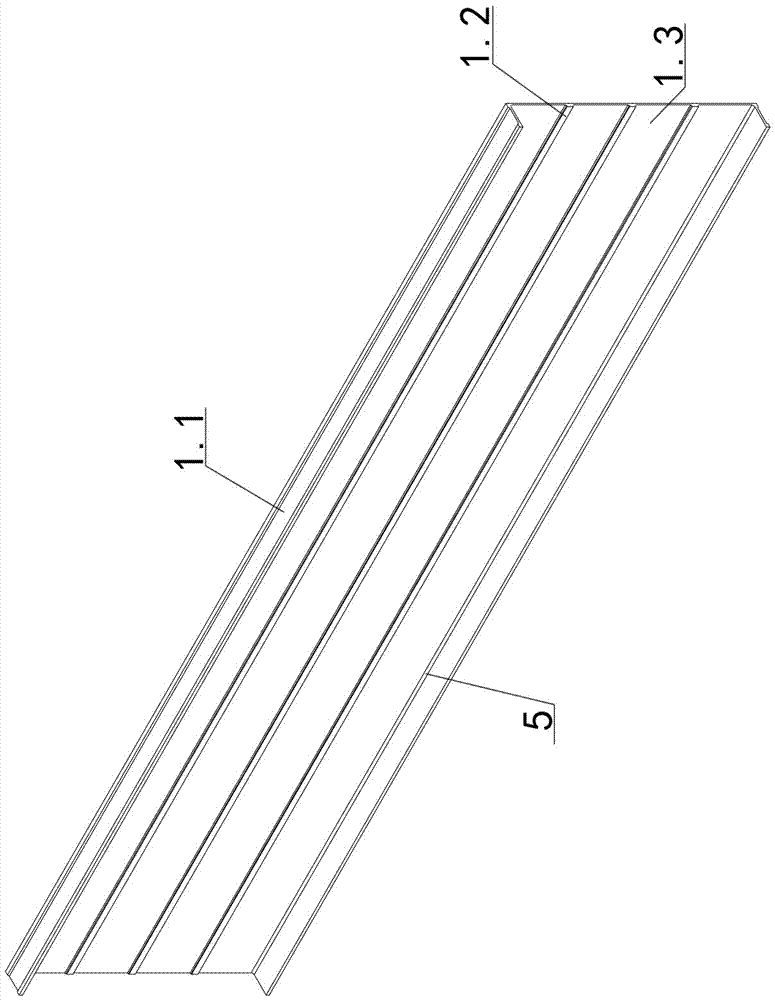

[0030] Examples see Figure 1-2 As shown, an aluminum alloy formwork protruding section profile is an aluminum alloy special-shaped plate 1 extruded as a whole. The aluminum alloy special-shaped plate 1 is composed of a rectangular panel 1.3 and two opposite longitudinal side frames 1.1 on the back of the panel. The formed tank body and the longitudinal protruding ribs 1.2 provided on the bottom of the tank body are composed of a cross-section of the longitudinal protruding ribs 1.2 in the shape of a boss, and the longitudinal protruding ribs 1.2 are arranged in the center of one or the space of the tank body More than two lines are evenly divided, and the longitudinal protruding ribs 1.2 and the rectangular panel 1.3 are transitionally connected by a concave arc 6, and the longitudinal side frame 1.1 and the rectangular panel 1.3 are connected by a chamfer 5.

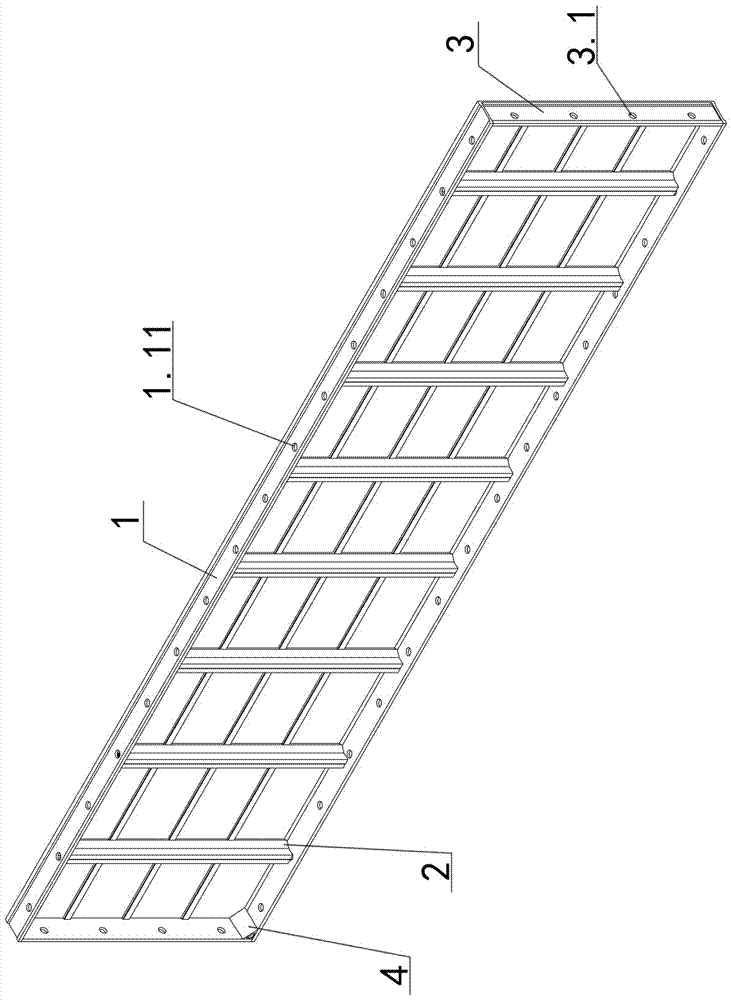

[0031] see Figure 3-4 As shown, a unit formwork structure of an aluminum alloy formwork includes the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com