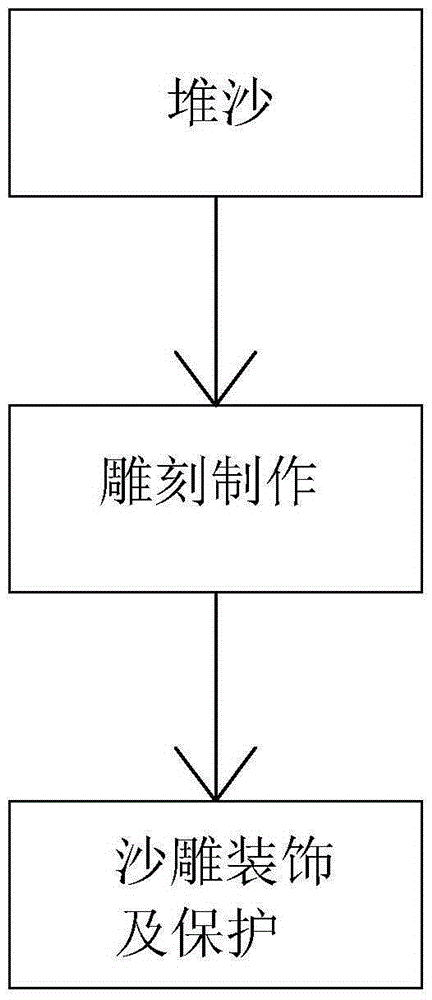

Sand sculpture manufacturing method

A sand sculpture production and sand sculpture technology, applied in the field of sand sculpture technology, can solve the problems of not being very large, unable to form a complete sand sculpture, unable to express, etc., to achieve the effect of improving stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

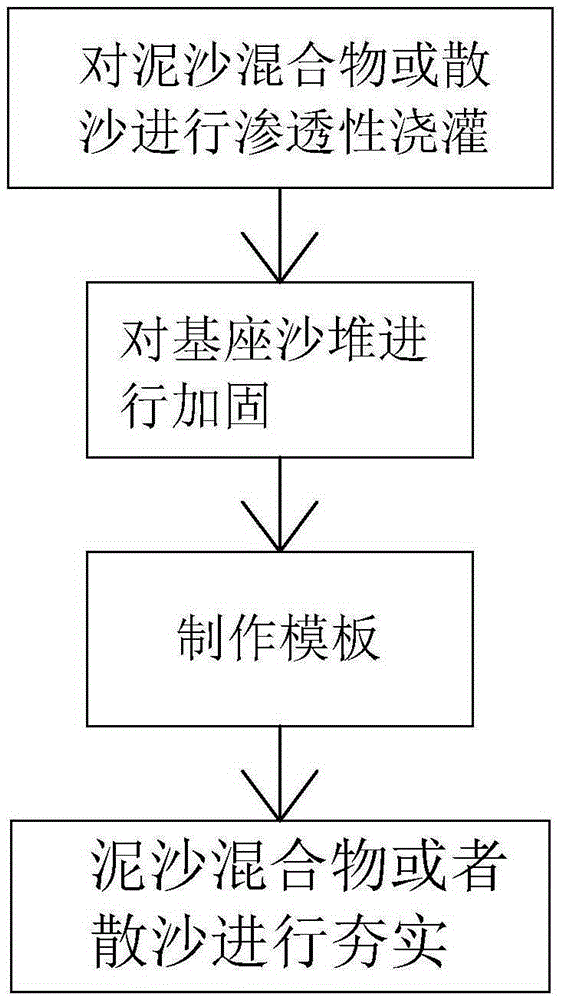

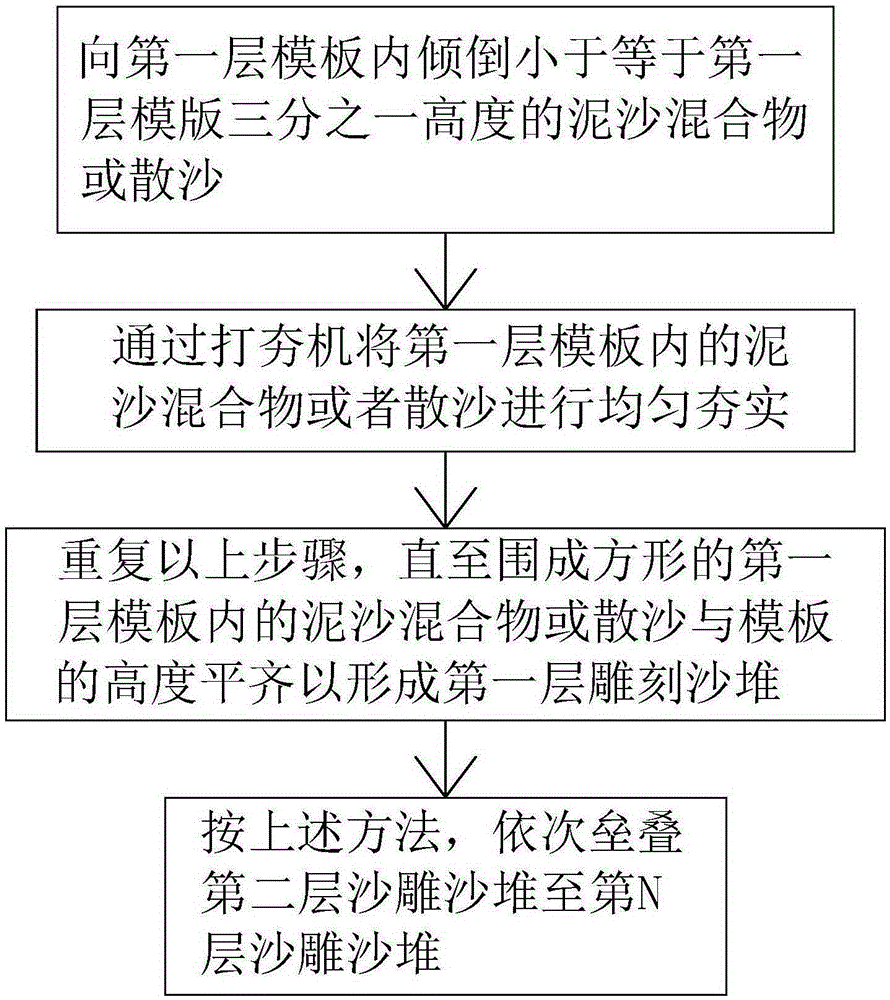

[0049] Embodiment 1: Sand can be piled up by using the method of wrapping templates, and using tools such as forklifts, ramming machines, water, loose sand, cement, templates, iron wires, and iron nails to achieve multi-layer accumulation, such as figure 2 As shown, it specifically includes the following steps:

[0050]First, in one embodiment, when the mud content of the loose sand is too low or the viscosity of the sand itself is too large to cause insufficient viscosity, the loose sand and cement are mixed with each other to form a sediment mixture, and the sand and mud mixture is mixed with water. Carry out permeable watering to make the mud-sand mixture completely wet. After a period of time, use a forklift to stack the sand-sand mixture that has undergone permeable watering into a base sand pile. The height and position of the base sand pile are determined by the sand sculptures carved . The mixing ratio of loose sand and cement is 40:1.

[0051] In one embodiment, wh...

Embodiment approach 2

[0074] Embodiment 2, not shown in the figure, loose sand artificial pile method, the steps are as follows:

[0075] First, the loose sand is directly piled up into a carved sand pile, and then the loose sand is irrigated with water to make the loose sand completely soaked. Among them, the general height of the carved sand pile is set to be approximately equal to 60cm, which can effectively avoid the collapse of the upper layer of loose sand due to excessive height.

[0076] Second, tamp the loose sand, and use a shovel to slap or trample the permeable sand from bottom to top. At the same time, regular and quantitative watering is required during the pat or trample process to avoid too little water and reduce its viscosity. , At the same time, it cannot be watered point-to-point, so as not to wash away the carved sand pile.

[0077] Carving production mainly consists of oil painting knives No. 1-30, watering cans, straws, special glue for sand sculpture, large and small trowel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com